Method for improving flotation of ilmenite by using titanium dioxide waste liquid

A technology of titanium dioxide waste liquid and ilmenite, which is applied in flotation, solid separation, etc., can solve the problems of pipeline blockage, high concentration cost, and high transportation cost, so as to improve the grade and recovery rate, improve the flotation index, and reduce the cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

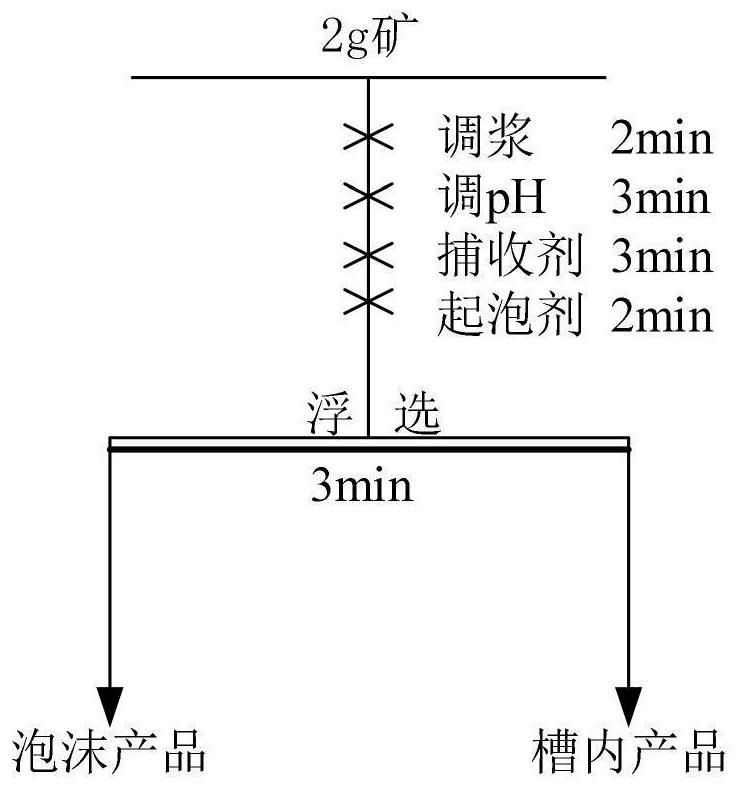

Method used

Image

Examples

Embodiment 1

[0050] What used in this embodiment is a certain titanium dioxide waste liquid in Chengde City, and its composition is shown in Table 1.

[0051] Table 1 Chemical composition of a titanium dioxide waste liquid in Chengde (g / L)

[0052]

[0053] The process of salicylic hydroxamate iron / titanium complex collector in the present embodiment is as follows:

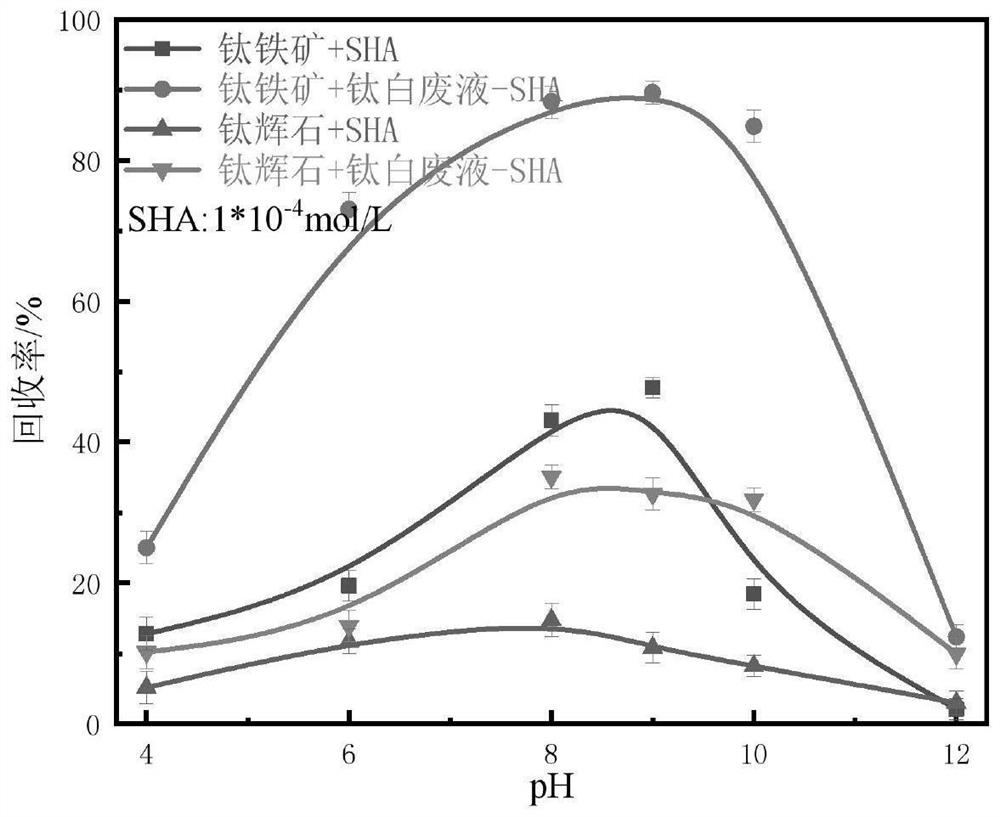

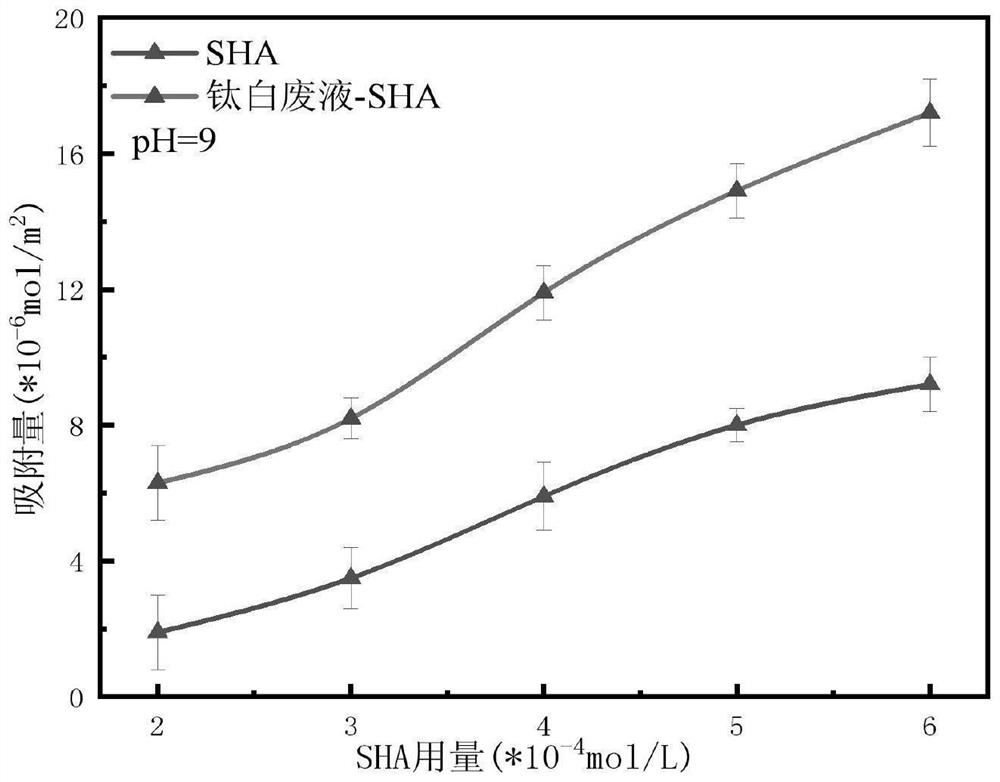

[0054] Get 10.40mL of this titanium dioxide waste liquid in a 100mL small beaker, add 1.53g salicylic hydroxamic acid in the beaker (the molar ratio of the iron ion and titanium ion total concentration in the titanium dioxide waste liquid and salicylic hydroxamic acid at this moment is 1.27:1 ) stirring reaction, the stirring speed is 180rpm, the reaction temperature is 25°C, and the reaction time is 5min to prepare the titanium-iron metal organic complex; then add 4.59g sodium oleate and 65.10mL water to the metal organic complex and stir the reaction, the stirring speed is 150rpm / min, the reaction temperature is 25°C, t...

Embodiment 2

[0062] What used in this embodiment is a certain titanium dioxide waste liquid from Panzhihua, and its composition is shown in Table 3.

[0063] Table 3 Chemical composition of a titanium dioxide waste liquid in Panzhihua (g / L)

[0064]

[0065] The process of salicylic hydroxamate iron / titanium complex collector in the present embodiment is as follows:

[0066] Take 9.50mL of titanium dioxide waste liquid in a 100mL small beaker, and add 1.53g of salicylic hydroxamic acid into the beaker (at this time, the molar ratio of the total concentration of iron ions and titanium ions in the titanium dioxide waste liquid to salicylic hydroxamic acid is 1.39:1) Stir the reaction, the stirring speed is 180rpm / min, the reaction temperature is 25°C, and the reaction time is 5min to prepare the titanium-iron metal organic complex; then add 4.59g sodium oleate and 66.00mL water to the metal organic complex and stir the reaction, the stirring speed 150rpm / min, reaction temperature 25°C, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com