Power supply device, electric vehicle using same, and power storage device

A power supply device and battery technology, which is applied to the arrangement of multiple different prime movers of general power plants, the arrangement of cooling combination of power plants, electric vehicles, etc., to reduce frictional resistance and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

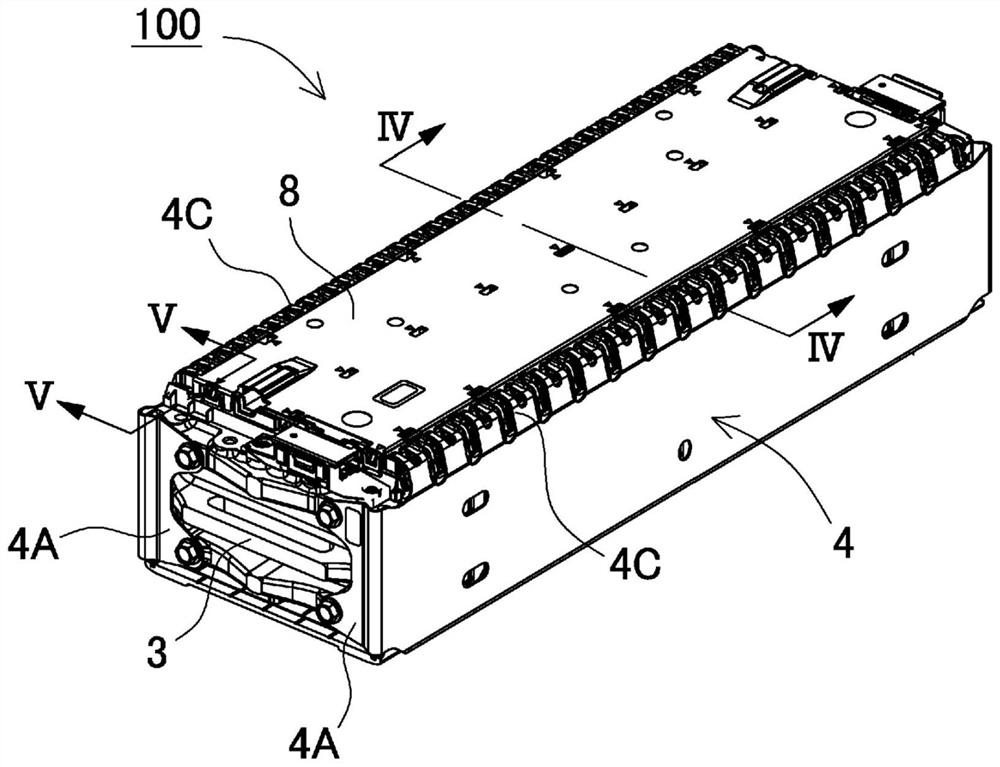

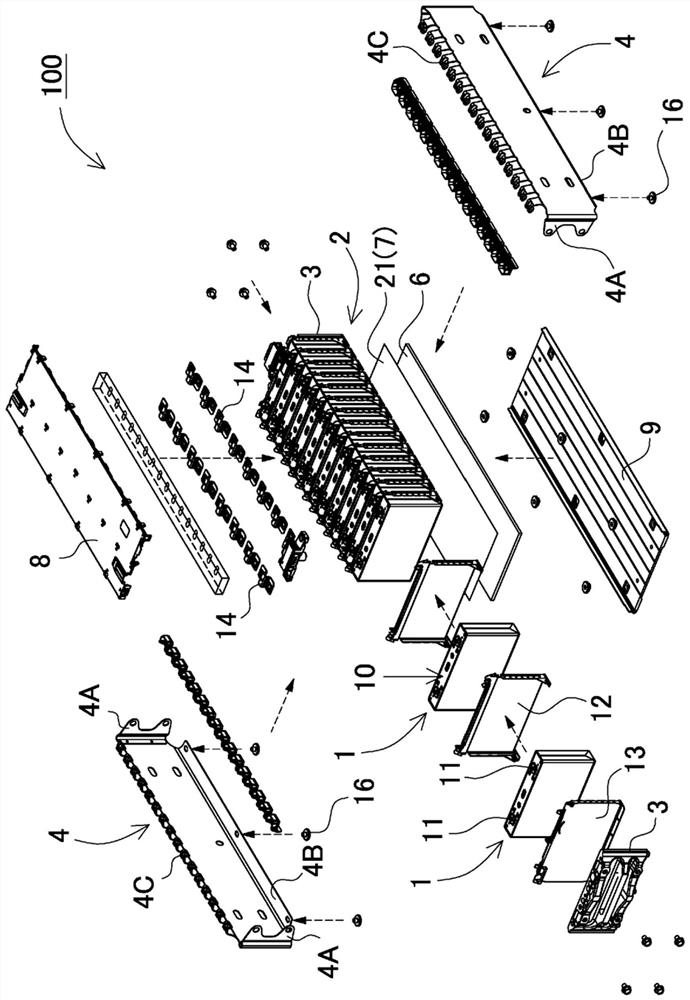

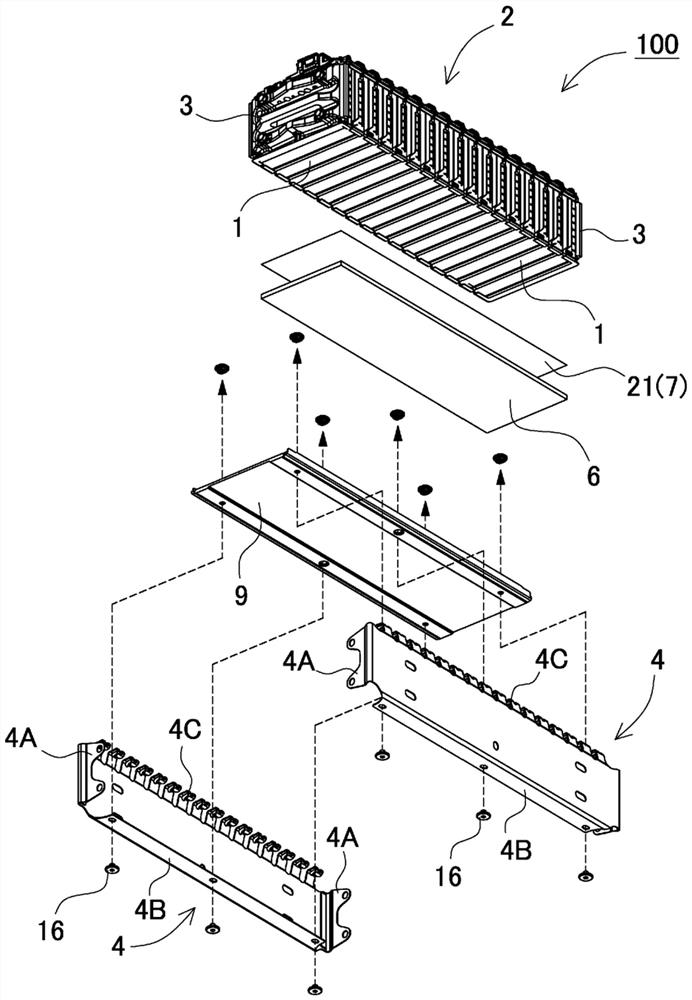

[0046] Figure 1 to Figure 5 Each shows a power supply device according to Embodiment 1 of the present invention. In these figures, figure 1 shows a perspective view of the power supply unit, figure 2 shows the view from obliquely above figure 1 The exploded perspective view of the power supply unit observed, image 3 shows the view from obliquely below figure 1 The exploded perspective view of the power supply unit observed, Figure 4 show figure 1 A vertical sectional view of the power supply unit along line IV-IV, Figure 5 show figure 1 The vertical section of the power supply device along the V-V line.

[0047] Such as Figure 1 to Figure 5 As shown, the power supply device 100 has: a plurality of battery cells 1, the external cans of which are set in a square shape; a pair of end plates 3, which cover both end faces of a battery stack 2 formed by stacking a plurality of battery cells 1; A plurality of tightening strips 4, which are plate-shaped extending ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com