A kind of preparation method of urea-formaldehyde foam material modified by shellac waste slag glue

A technology of urea-formaldehyde foam and shellac, which is applied in the field of preparation of urea-formaldehyde foam materials, can solve problems such as waste of natural resources, waste of shellac residue glue, performance defects, etc., and achieves improvement of brittleness and cracking, low biodegradability, good The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of preparation method of the urea-formaldehyde foam material modified by lac waste slag glue, concrete operation steps are:

[0041] (1) Treatment of waste lac residue: heat waste lac residue at 80°C for 12 hours in a vacuum to remove moisture from waste lac residue (WS) to obtain dehydrated waste lac residue (referred to as T-WS ).

[0042] (2) Preparation of shellac waste slag modified urea-formaldehyde resin: (a) 100g of formaldehyde solution (37%) was added to the reaction flask, 3.5g of hexamethylenetetramine was added, and 30% NaOH solution was added dropwise under stirring to pH 7.5, heat up to 40°C, add the first batch of 24g of urea and T-WS mixture (T-WS / urea mass ratio is 1 / 4), slowly reflux and heat up to 60°C, keep warm for 30min; (b) add the second Batch 12g of urea and T-WS mixture (T-WS / urea mass ratio is 1 / 4), keep it warm for 25min, then rapidly raise the temperature to 85°C within 15min, keep it warm for 25min, adjust the pH to 4.5 with 10% fo...

Embodiment 2

[0045] A kind of preparation method of the urea-formaldehyde foam material modified by lac waste slag glue, concrete operation steps are:

[0046] Adjust the step (2) to: (a) Add 100g of formaldehyde solution (37%) to the reaction flask, add 3.5g of hexamethylenetetramine, add dropwise 30% NaOH solution to pH 8.2 under stirring, and heat up to 45°C , add the first batch of 24g of urea and T-WS mixture (the mass ratio of T-WS / urea is 1 / 3), slowly reflux and heat up to 55°C, and keep warm for 35min; (b) Add the second batch of 12g of urea and T-WS WS mixture (T-WS / urea mass ratio is 1 / 3), keep warm for 35min, then rapidly heat up to 90°C within 20min, keep warm for 35min, adjust the pH to 5.5 with 10% formic acid, and observe the change of liquid viscosity in the reaction bottle, until turbid, immediately with 25-28% NH 3 Adjust the pH to 7.5 with water, and adjust the pH to 8.2 with 30% NaOH solution after dehydration under reduced pressure; (c) Cool to below 60°C, add the thi...

Embodiment 3

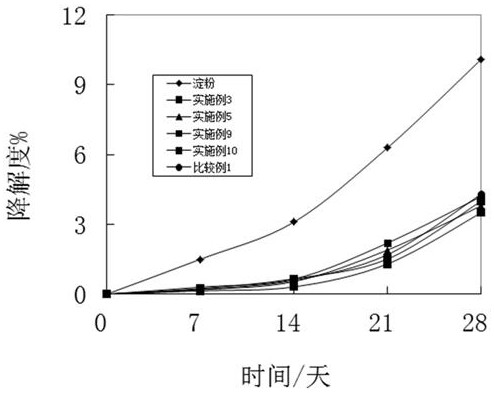

[0049] A kind of preparation method of the urea-formaldehyde foam material modified by lac waste slag glue, concrete operation steps are: repeat embodiment 1, only adjust the mass ratio of T-WS / urea in step (2) to 1 / 2, step (3 ) The mass fraction of sodium bicarbonate in ) was adjusted to 2.5% (2.5g), and the amount of its aqueous solution was adjusted to 25g. The measured solid content of WS-UFR is 55.7%, the viscosity is 130s, and the pH value is 7.8; the measured apparent density of WS-URF is 0.26g / cm 3 , Compression strength is 234.4Kpa, free formaldehyde content is 0.23%, no cracking phenomenon, pulverization rate is 3.0%, thermal conductivity is 0.034W / m.K, 28d biodegradation degree is 4.2%.

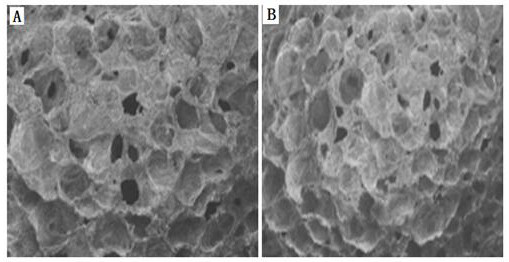

[0050] figure 1 A is an electron microscope photo of the shellac waste slag modified urea-formaldehyde foam material obtained in this example. It can be seen from the figure that this example can produce a foam material with relatively uniform cell and cell wall thickness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pulverization rate | aaaaa | aaaaa |

| pulverization rate | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com