Grain boundary diffusion method for improving diffusion performance of R-T-B magnet

A technology of R-T-B and grain boundary diffusion, applied in the direction of magnetic objects, magnetic materials, inductors/transformers/magnets, etc., can solve problems such as Br drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

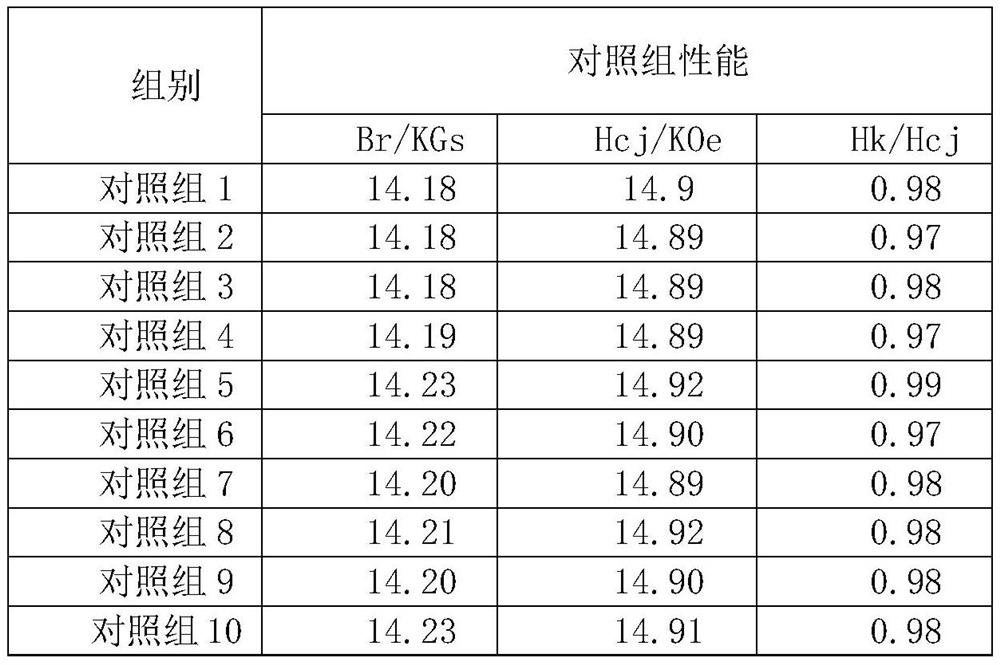

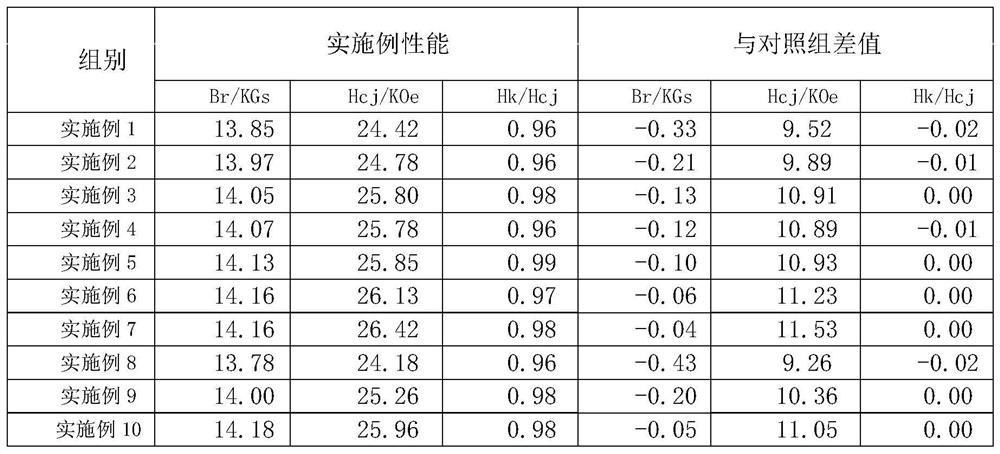

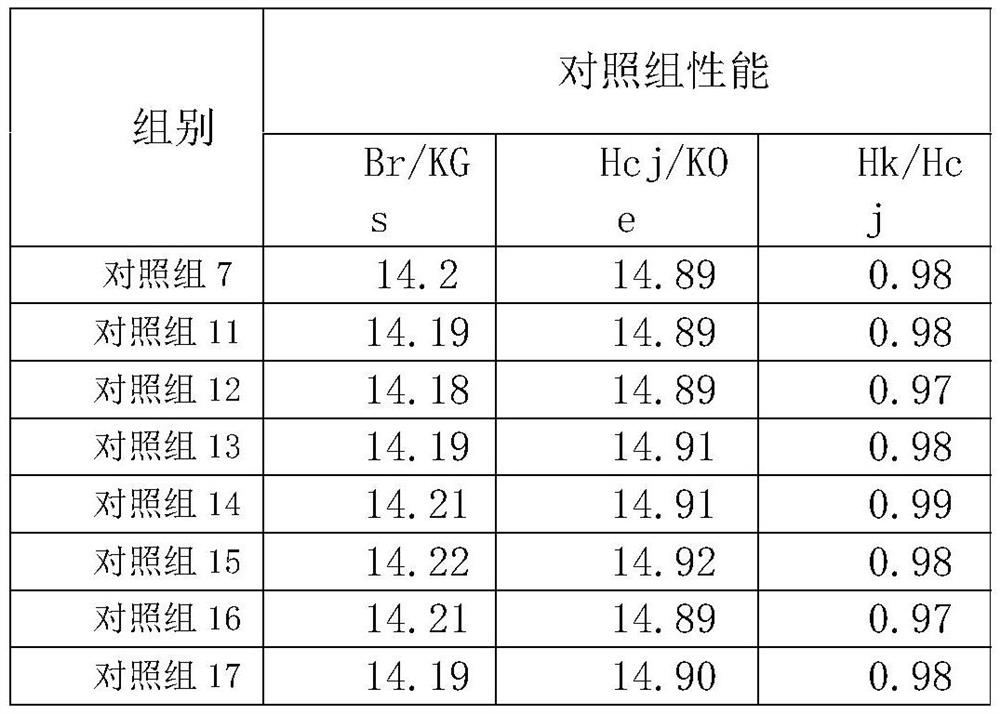

Examples

Embodiment 1

[0027] (1) Several magnets with brand N48M were selected from the product warehouse of our company. In order to facilitate the follow-up performance test, the magnet is wire-cut into several small magnetic steels of φ10*5mm, which are used as the experimental substrate. In actual production, the shape of the magnet base is not limited.

[0028] Cover the diffusion source Tb to the surface of the substrate, and use the physical vapor deposition method: on the φ10mm*5mm magnetic steel, perform magnetron sputtering physical vapor deposition in the plasma vacuum coating machine, and the atmosphere source is high-purity Ar. The principle is After the high-voltage glow discharge, the magnetic field is used to bind the accelerated electrons to bombard the Ar atoms and form a plasma, and then the electric field and the magnetic field are used to control the Ar+ ions to bombard the target, so that the Tb atoms are dispersed in the cavity after sputtering; finally, the gravity field is ...

Embodiment 2

[0034] Embodiment 2: The same as the preparation method of Embodiment 1, the difference is that the absolute vacuum degree is adjusted to 4.0*10 -2 Pa.

Embodiment 3

[0035] Embodiment 3: The preparation method is the same as that of Embodiment 1, except that the absolute vacuum degree is adjusted to 3.6kpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com