Surface mount type multi-surface rotating mirror scanning system and manufacturing method thereof

A scanning system and patch technology, applied in the field of optical scanning systems, can solve the problems of surface deterioration, system failure, inability to meet, etc., and achieve the effect of reducing production difficulty, improving reliability, and stabilizing work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

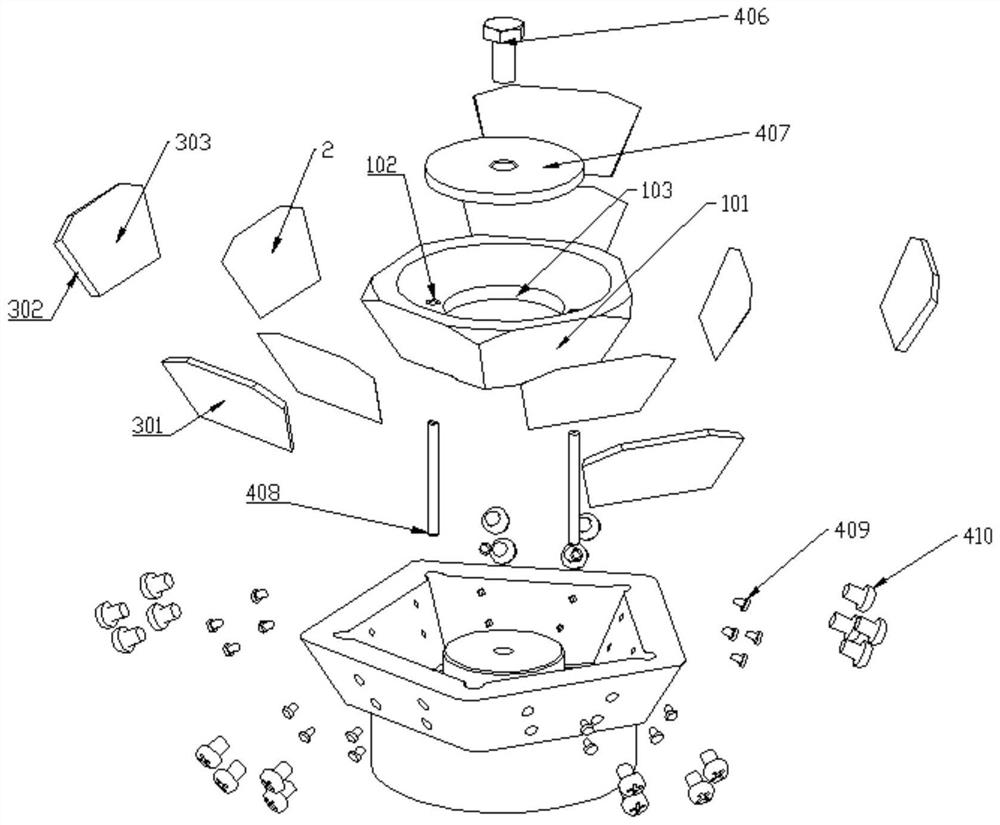

[0021] Such as figure 1 As shown, the patch-type multi-faceted mirror scanning system in this embodiment includes a base, a mirror, a soldering piece, and special tools for assisting welding.

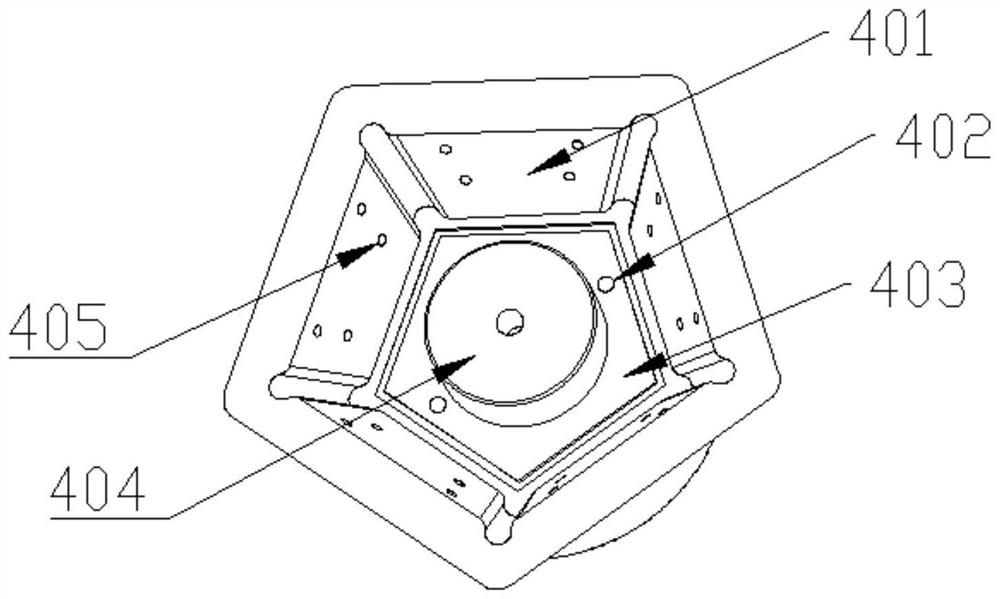

[0022] figure 1 Among them, number 1 is the base, including a positioning plane 101 , a positioning hole 102 and a mounting hole 103 . Among them, 101, the positioning plane 101 usually has a roughness of not more than 2 microns and a dyne value of not less than 28; the positioning hole 102 is used for positioning with the positioning rod 408 and the positioning hole 402 on the welding tool during welding. The mounting hole 103 is used for clearance fit with the positioning column 404 during welding, and is used for positioning; the mounting hole 103 is used for matching with the motor shaft (not shown in the figure) after welding to drive the base 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com