High-temperature viscosity tester for continuous casting covering slag

A technology for continuous casting mold flux and viscosity measurement, which is applied in the direction of instruments, measuring devices, scientific instruments, etc. The insertion depth of the head cannot be controlled, etc., to achieve a high degree of automation, a scientific and reasonable design structure, and the effect of improving mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

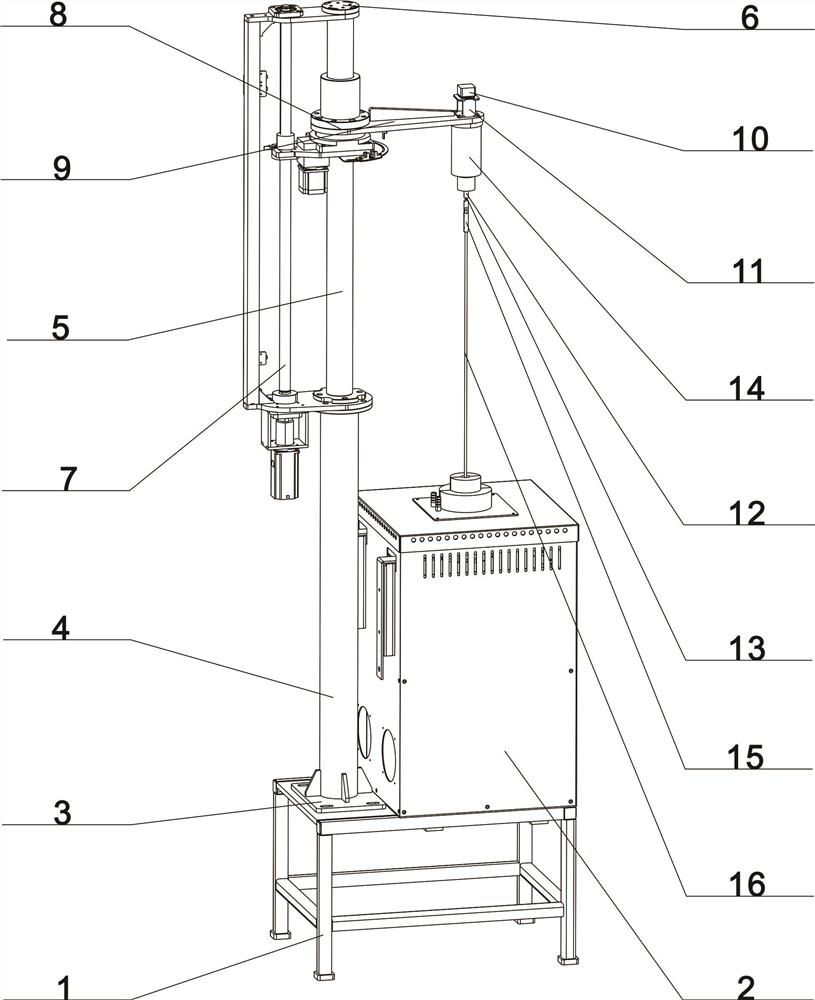

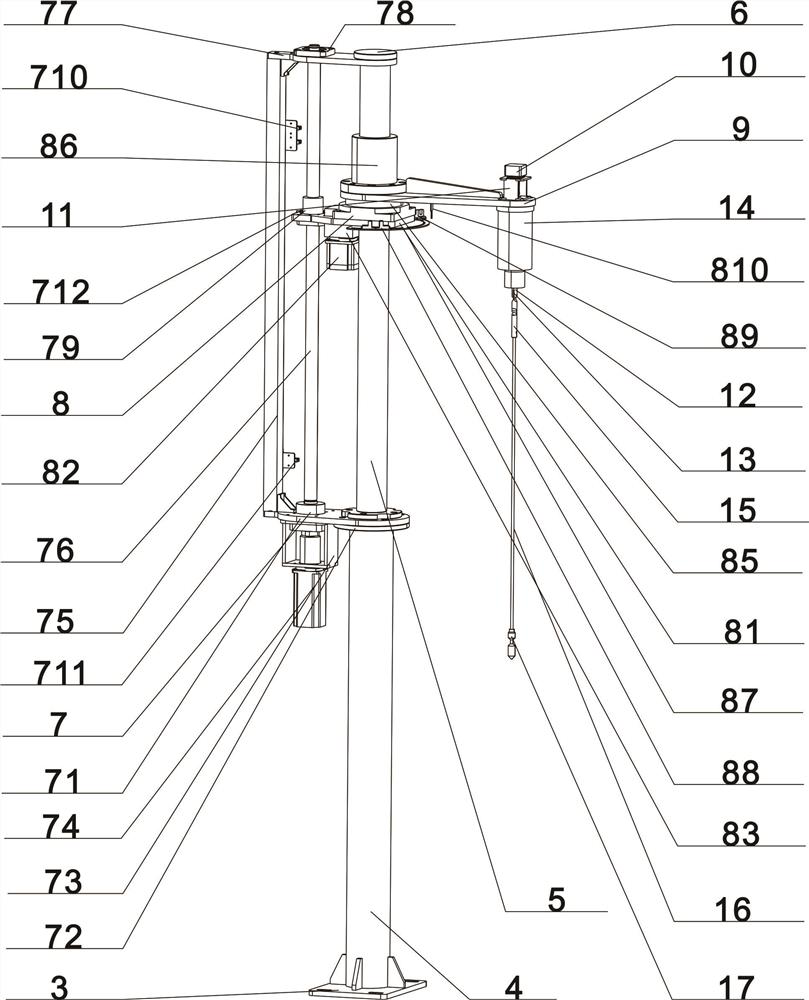

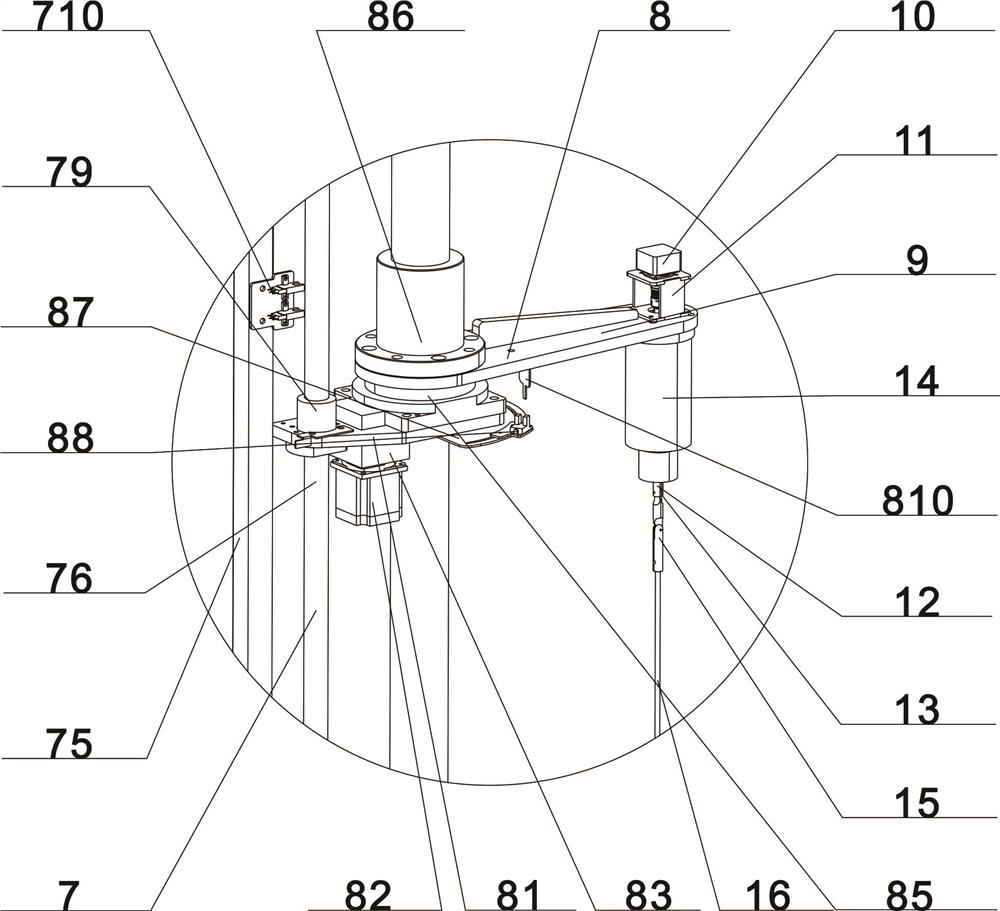

[0030] As shown in the figure, the present invention provides a high-temperature viscosity measuring instrument for continuous casting mold flux, which includes a support 1, a heating furnace 2 and a base 3; the support 1 is a square structure, and the upper left side of the support 1 is fixed with a base 3, A heating furnace 2 is fixedly installed on the right side of the base 3, and the heating furnace 2 is used for high-temperature melting of continuous casting mold slag. The upper column 5 is fixedly arranged; the bottom of the lifting device 7 is fixedly arranged at the upper end position of the bottom column 4, and the upper part of the lifting device 7 is fixedly arranged at the upper end of the upper column 5, and is fixed by the fixed flange 6; the rotating swing device 8 The left side is installed on the liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com