Preparation method of phosphorus-doped graphene fiber modified by cobaltosic oxide nanowire, product prepared by preparation method and application of product

A technology of nano-cobalt tetroxide and phosphorus-doped graphene, which is applied in the fields of cobalt oxide/cobalt hydroxide, fiber chemical characteristics, and material electrochemical variables, and can solve the problems of large demand for doping sources, inability to prepare batches, and cumbersome processes, etc. , to achieve the effect of increasing the specific surface area, accelerating the contact sufficiency, and being environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of the cobalt tetroxide nanowire array modified phosphorus-doped graphene fiber of the present invention is described in detail below, which comprises the following steps:

[0049] S1, mixing phytic acid and graphene oxide solution with a mass ratio of 0.5-2 to obtain a spinning dope, and using a wet spinning process to prepare phytic acid-graphene oxide fibers.

[0050] S2, the phytic acid-graphene oxide fiber obtained in S1 is subjected to reduction treatment, and the fiber after the reduction treatment is washed and dried to obtain the phytic acid-graphene fiber.

[0051] S3, the phytic acid-graphene fibers obtained in S2 and the reaction solution comprising cobalt nitrate and 2,4-dihydroxybenzoic acid are placed in a closed system for solvothermal reaction, and the fibers after the reaction are cleaned and dried to obtain cobalt-based Nanowire arrays decorate graphene fibers.

[0052] S4, the cobalt-based nanowire array modified graphene fibe...

Embodiment 1

[0070] 2.5mmol Co (NO 3 ) 2 and 1 mmol 2,4-dihydroxybenzoic acid was added to 39 mL mixed solution, wherein the mixed solution was a mixed solution of ethanol, water and dimethylformamide, and their volume ratio was 1:1:1, and stirred for 30 After min, the reaction solution was obtained, and the reaction solution was transferred to a tetrafluoroethylene liner, and 20 pieces of S2 were added to obtain phytic acid-graphene fibers. After reacting for 20 hours, after cooling to room temperature, the reacted fibers were taken out, washed with ethanol and water for 3-4 times, and dried in vacuum at 70°C to obtain cobalt-based nanowire array modified graphene fibers and packaged and stored.

[0071] The obtained cobalt-based nanowire array modified graphene fibers were placed in a quartz boat and placed in a tube furnace. , and cooled to obtain cobalt tetroxide nanowire array modified phosphorus-doped graphene fibers.

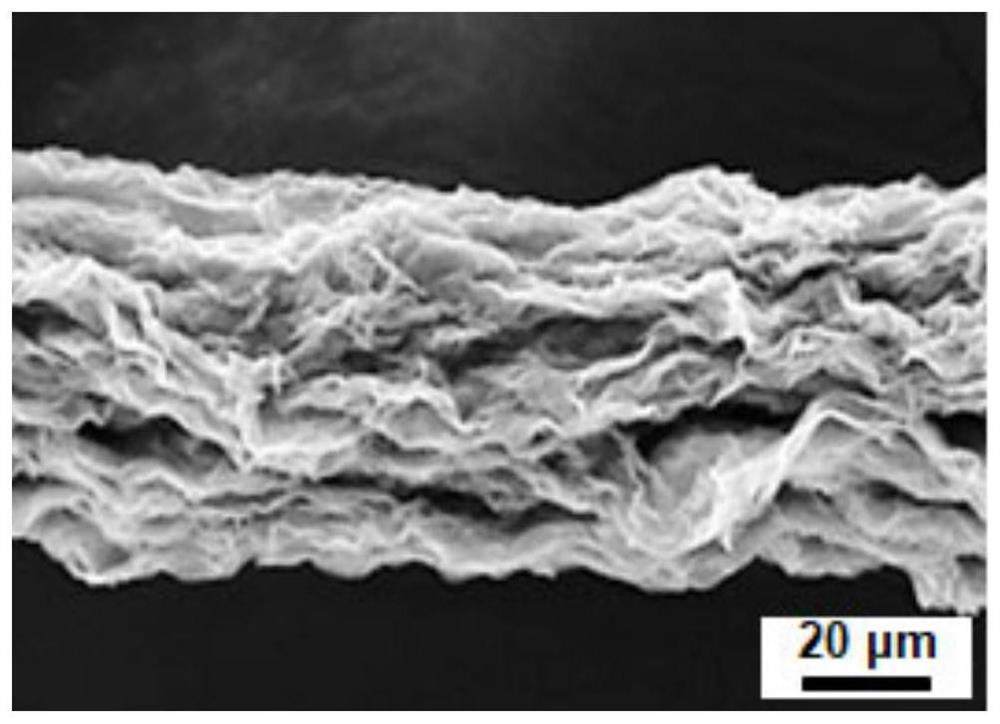

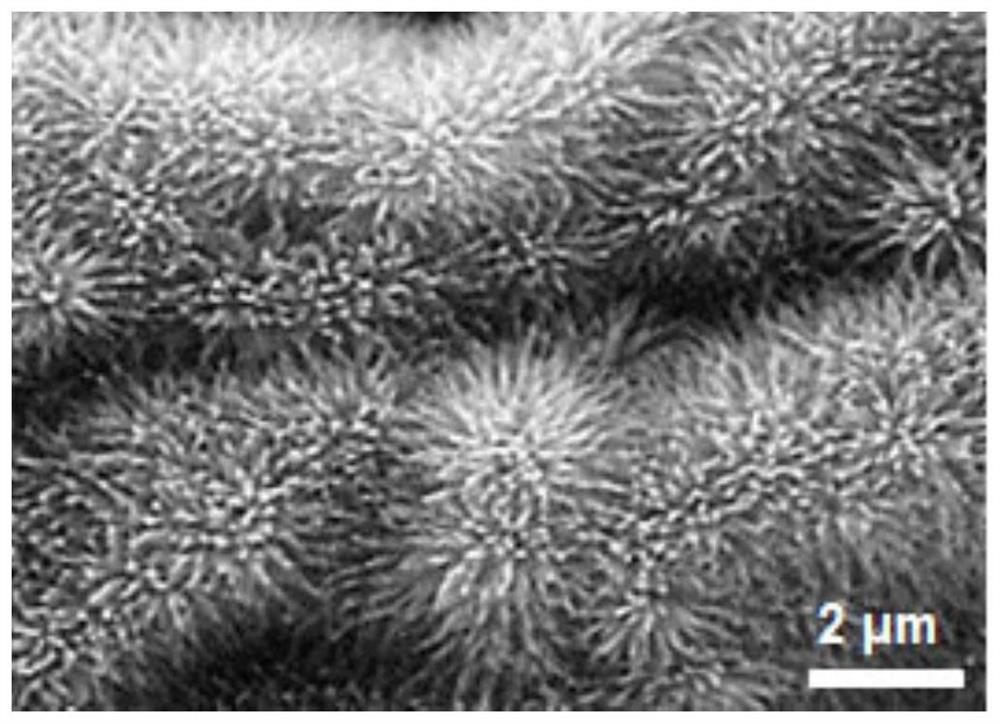

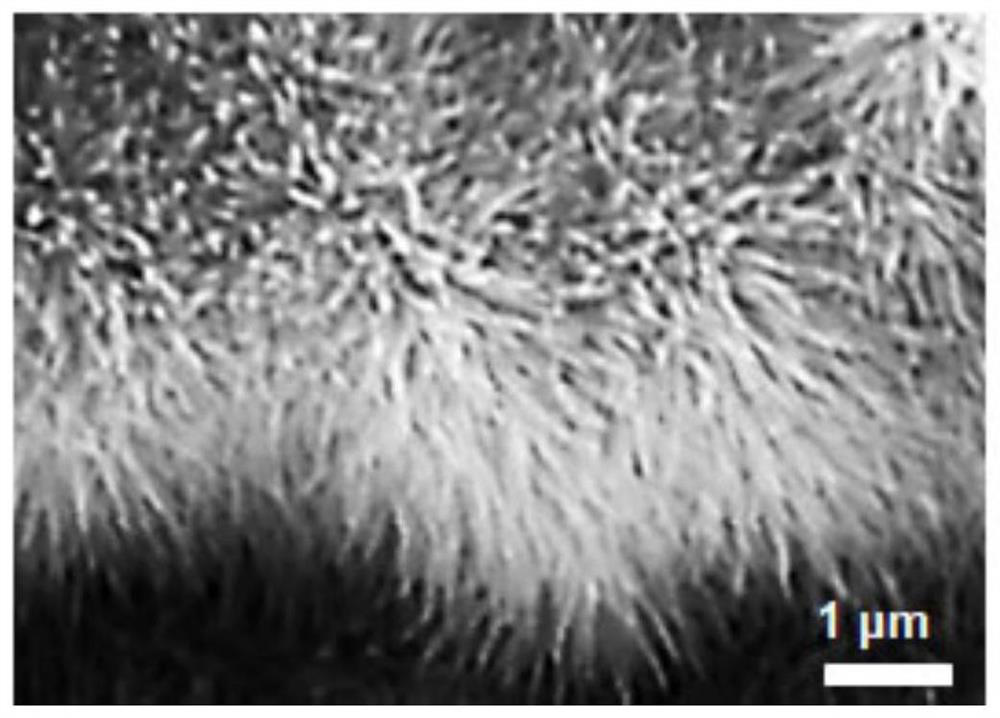

[0072] figure 1 , Figure 2-1 , Figure 2-2 Scanning elect...

Embodiment 2

[0079] 2.5mmol Co (NO 3 ) 2 and 1 mmol 2,4-dihydroxybenzoic acid was added to 39 mL mixed solution, wherein the mixed solution was a mixed solution of ethanol, water and dimethylformamide, and their volume ratio was 1:1:1, and stirred for 30 After min, the reaction solution was obtained, and the reaction solution was transferred to a tetrafluoroethylene liner, and 20 pieces of S2 were added to obtain phytic acid-graphene fibers. After reacting for 20 hours, after cooling to room temperature, the reacted fibers were taken out, washed with ethanol and water for 3-4 times, and dried in vacuum at 70°C to obtain cobalt-based nanowire array modified graphene fibers and packaged and stored.

[0080] The obtained cobalt-based nanowire array modified graphene fibers were placed in a quartz boat and placed in a tube furnace. , and cooled to obtain cobalt tetroxide nanowire array modified phosphorus-doped graphene fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com