Preparation method of silicon doping carbon quantum dots by adoption of solvothermal method and applications thereof

A technology of carbon quantum dots and solvothermal method, which is applied in the direction of biochemical equipment and methods, chemical instruments and methods, nano-carbon, etc., can solve problems such as limiting biological science applications, not being environmentally friendly, and emitting wavelength shifts, etc., to achieve easy Popularization, simple preparation process and equipment, good light fastness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: The method for preparing silicon-doped carbon quantum dots by one-step solvothermal method

[0025] Weigh 0.97g of hydroquinone, place it in a 25mL stainless steel high-pressure reactor lined with polytetrafluoroethylene, add 5mL of acetone to dissolve, transfer 1.00mL of silicon tetrachloride into the above-mentioned reactor slowly, and The sealed reaction kettle was placed in a blast drying oven and heated at 200° C. for 2 hours. When the autoclave is cooled to room temperature, the mixed liquid in the autoclave is concentrated and evaporated to dryness by means of rotary evaporation to obtain silicon-doped carbon quantum dots.

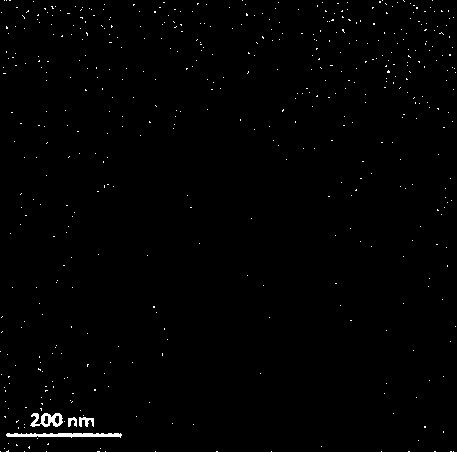

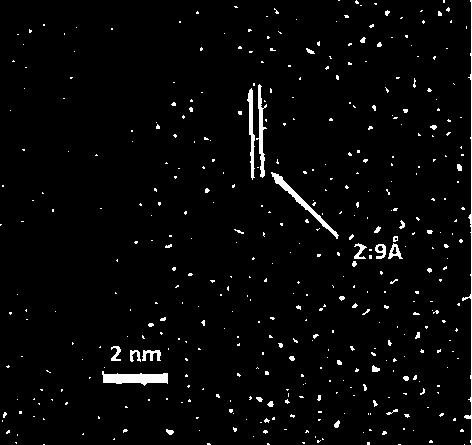

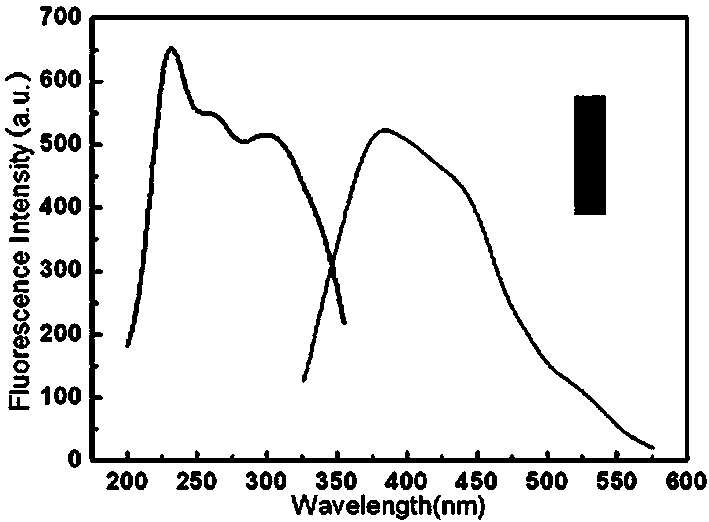

[0026] Such as figure 1 TEM imaging shows that silicon-doped carbon quantum dots are monodisperse and uniform spherical, and the particle size is mainly distributed in the range of 5-15nm. Such as figure 2 The high-resolution transmission electron microscope photos in the paper show that silicon-doped carbon quantum dots hav...

Embodiment 2

[0034] Embodiment 2: the method for preparing silicon-doped carbon quantum dots by one-step solvothermal method

[0035] Weigh 0.97g of hydroquinone, place it in a 25mL stainless steel high-pressure reactor lined with polytetrafluoroethylene, add 5mL of acetone to dissolve, pipette 2.00mL of silicon tetrachloride and slowly drop it into the above-mentioned reactor. The sealed reaction kettle was placed in a blast drying oven and heated at 150° C. for 1 hour. When the autoclave is cooled to room temperature, the mixed liquid in the autoclave is concentrated and evaporated to dryness by means of rotary evaporation to obtain boron-doped carbon quantum dots.

[0036] Use the reference method to measure the fluorescence quantum yield, the calculation formula is: Ф=Ф S [(I·A s n 2 ) / (I s ·A·n s 2 )] (Ф represents the quantum yield, I represents the integrated area of the fluorescence emission spectrum under the excitation of the optimal excitation wavelength, A represents th...

Embodiment 3

[0044] Embodiment 3: the method for preparing silicon-doped carbon quantum dots by one-step solvothermal method

[0045] Weigh 0.97g of hydroquinone, place it in a 25mL stainless steel autoclave lined with polytetrafluoroethylene, add 5mL of acetone to dissolve, pipette 3.00mL of silicon tetrachloride and slowly drop it into the above-mentioned reaction kettle. The sealed reaction kettle was placed in a blast oven and heated at 220° C. for 5 hours. When the autoclave is cooled to room temperature, the mixed liquid in the autoclave is concentrated and evaporated to dryness by means of rotary evaporation to obtain silicon-doped carbon quantum dots.

[0046] Use the reference method to measure the fluorescence quantum yield, the calculation formula is: Ф=Ф S [(I·A s n 2 ) / (I s ·A·n s 2 )] (Ф represents the quantum yield, I represents the integrated area of the fluorescence emission spectrum under the excitation of the optimal excitation wavelength, A represents the absorb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com