Pure zinc coated steel plate with good dezincification resistance and surface quality as well as production method and application of pure zinc coated steel plate

A surface quality, coated steel technology, applied in the direction of coating, hot-dip plating process, metal material coating process, etc., can solve the problems of too high P content, high P content, easy cracking in stamping, etc., to achieve a wide range Application prospects, simple manufacturing method, and the effect of reducing waste of resources

Active Publication Date: 2022-05-06

MAANSHAN IRON & STEEL CO LTD

View PDF14 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the high content of C (≥0.002wt%), it is unfavorable to obtain more excellent deep drawing performance. At the same time, the content of P is too high, the strip steel is difficult to clean, and it is easy to compound with Mn during the continuous annealing process. Solid solution strengthening effect, precipitates bonded to furnace rolls Long-term continuous production may easily cause furnace roll nodules and damage the surface, resulting in pinpoint missing plating defects in the subsequent hot-dip galvanizing process

This document also does not introduce how to control the quality of the surface zinc layer to obtain excellent anti-dezincification powder performance

[0005]A patent document with publication number CN 110172637 A published on August 27, 2019 discloses a high-strength interstitial atom-free steel strip for 340MPa deep drawing and its preparation method, the chemical composition does not contain Nb, which is unfavorable for obtaining stable hot-dip coating and mechanical properties

At the same time, if the P content is too high, it is easy to cause pinpoint missing plating

There is no mention of how to control the surface quality of the zinc layer to obtain excellent anti-dezincification powder performance, and the yield strength of the product shown in the examples is too high (≥235MPa), and stamping is prone to cracking problems

[0006]A patent document published on April 29, 2015 with the publication number CN104561788A discloses a phosphorus-containing high-strength interstitial atom-free steel and its production method. At the same time, the P content is added If it is too high, it is easy to cause pinpoint missed plating

And the method claimed in the invention patent is only applicable to the field of bell annealing, not suitable for the field of hot-dip galvanizing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1- Embodiment 6

[0070] The pure zinc-coated steel sheet with good dezincification powder resistance and surface quality includes the chemical composition in the mass percentage amount shown in Table 1, and the balance not shown in Table 1 is Fe and unavoidable impurities.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Login to View More

Abstract

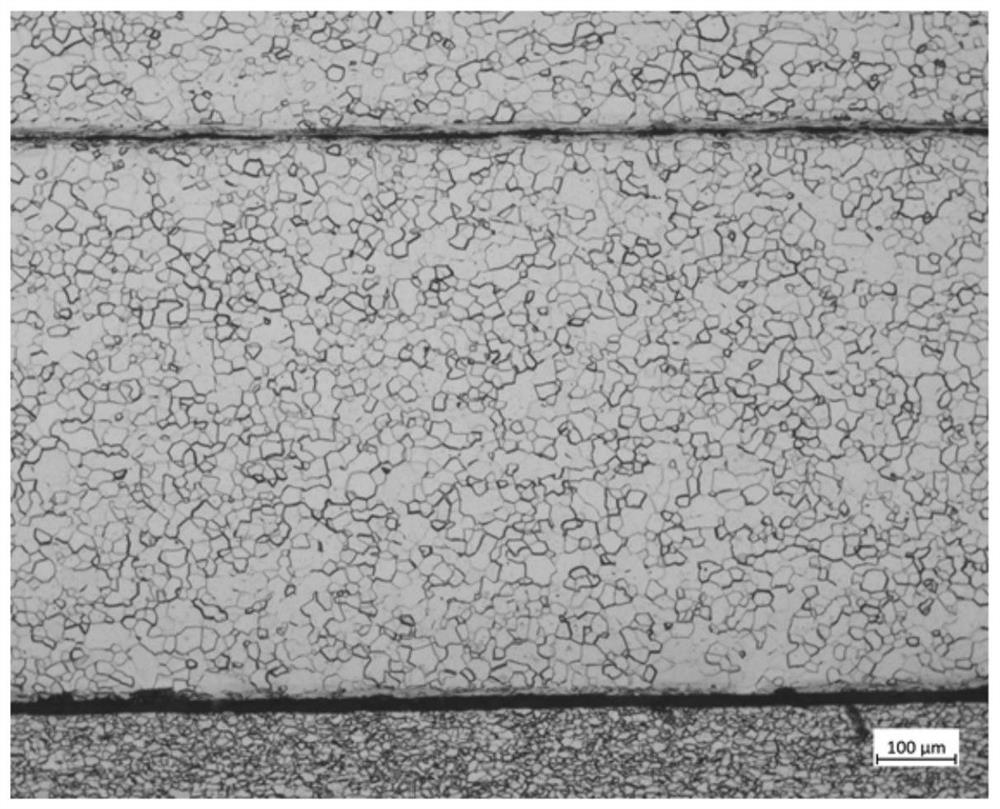

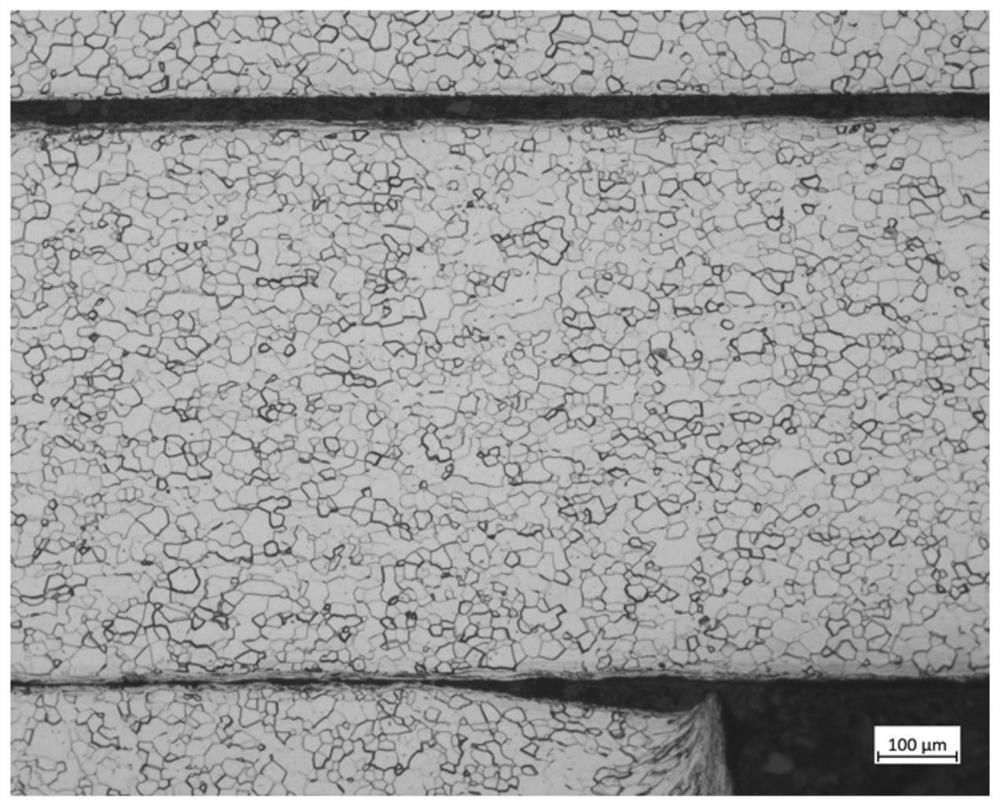

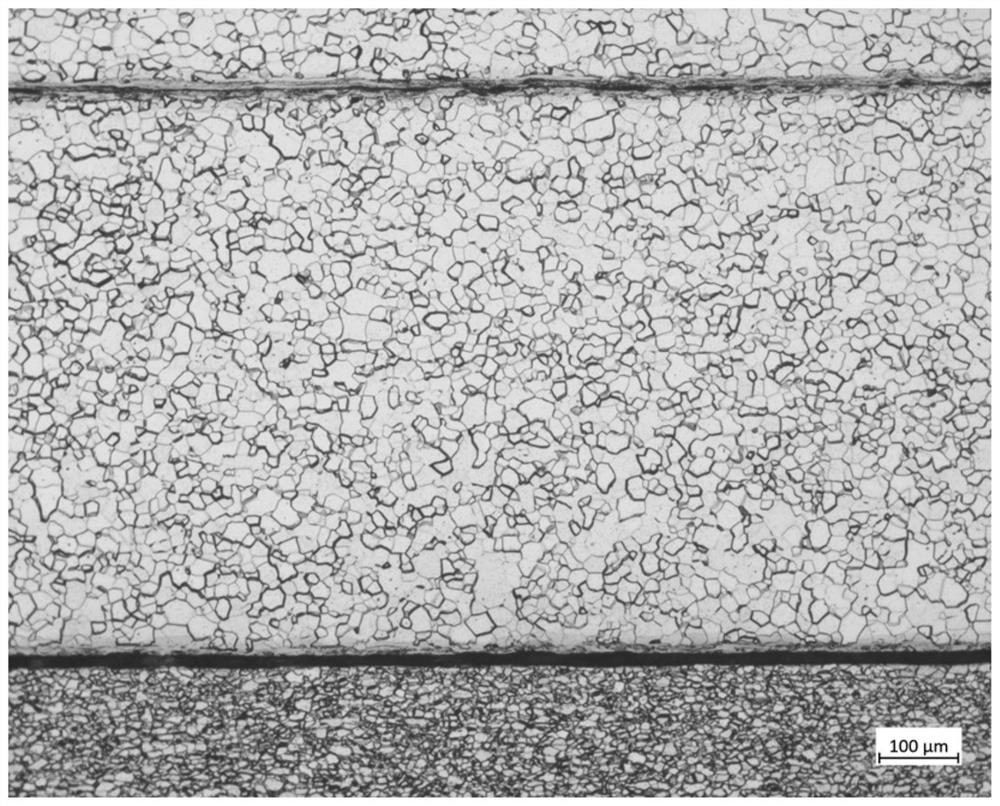

The invention provides a pure zinc coated steel plate with good dezincification resistance and surface quality as well as a production method and application of the pure zinc coated steel plate. The steel comprises the following components in percentage by weight: 0.001 to 0.0025 percent of C, 0.05 to 0.10 percent of Si, 0.4 to 0.6 percent of Mn, 0.03 to 0.05 percent of Al, 0.025 to 0.035 percent of Ti, 0.015 to 0.025 percent of Nb, less than or equal to 0.004 percent of N, 0.0002 to 0.0008 percent of B, 0.02 to 0.03 percent of P, less than or equal to 0.008 percent of S and the balance of Fe and inevitable impurities. Compared with the prior art, needle-point-shaped skip plating points with the diameter of 0.1-1.0 mu m are prevented from appearing on the surface through chemical components and matched process design. And meanwhile, by designing the concentration of the finishing liquid and the high-pressure water process design, it is ensured that the bottoms of the surface finishing pits are smooth and free of mechanical damage, and the zinc layer cannot be accumulated in the mold to pollute the mold even if falling off during stamping plastic deformation.

Description

technical field [0001] The invention belongs to the field of galvanized automobile steel manufacturing, and relates to a pure zinc-coated steel plate with a tensile strength of 350 MPa and a production method and application thereof with good anti-dezincification powder performance and surface quality. The production method involved in the present invention is suitable for pure zinc-coated steel sheets with a specified minimum tensile strength of 350 MPa, and is suitable for producing automobile engine hood outer panels, door outer panels, and top cover outer panels with strict deep drawing performance and surface quality requirements. boards and other parts. Background technique [0002] The vigorous development of the automobile industry has put forward higher requirements for the materials used in auto parts. In addition to the new requirements of energy saving and emission reduction, carbon peaking, and carbon neutrality put forward by the state this year, the galvanized...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/02C22C38/04C22C38/06C22C38/12C22C38/14C23C2/06C23C2/26C23C2/40C21D1/26C21D6/00C21D8/02

CPCC22C38/004C22C38/02C22C38/04C22C38/06C22C38/14C22C38/12C22C38/002C21D1/26C21D6/005C21D6/008C21D8/0205C21D8/0226C21D8/0236C23C2/06C23C2/40C23C2/26C21D8/0273C21D2211/005

Inventor 葛浩刘珂刘东亚单梅陈友志崔磊马奇骥周红兵

Owner MAANSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com