Preparation method and application of high-absorbance honeycomb polyamide membrane

A polyamide and honeycomb technology, which is applied in the field of preparation of honeycomb polyamide films, can solve the problems affecting the performance of polyamide plastics, lack of performance, etc., and achieves low production cost, good film-forming properties, and improved hydrophilicity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

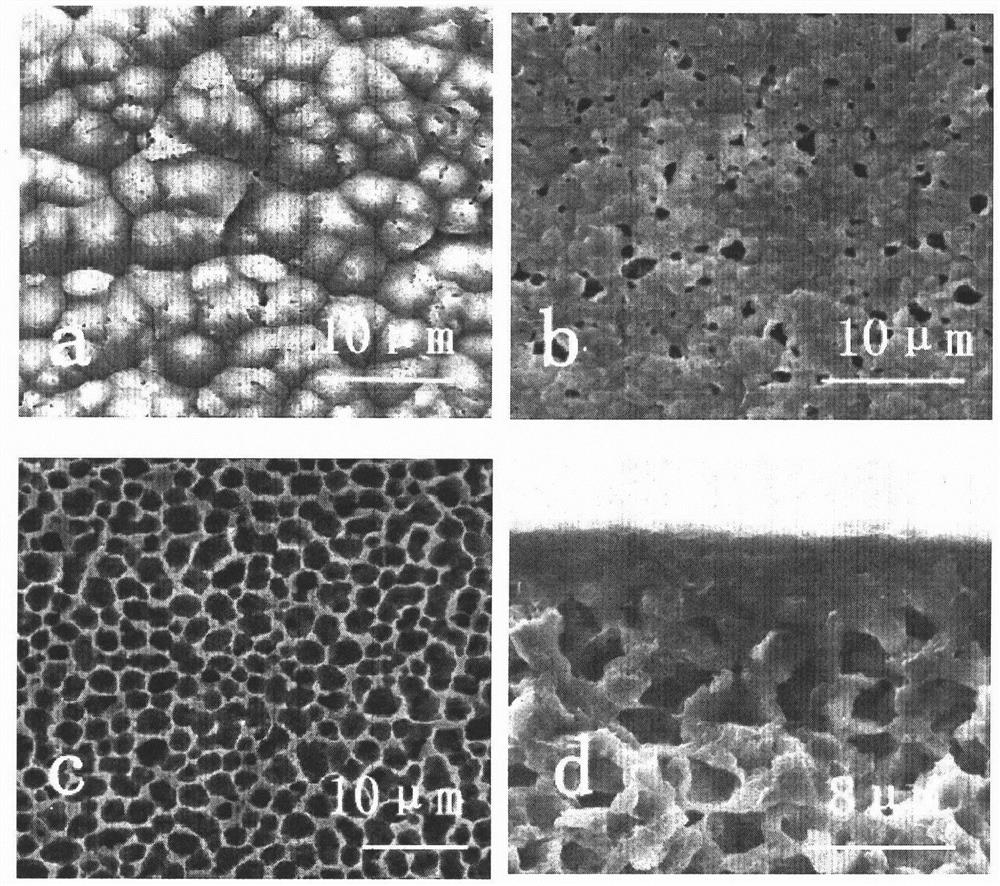

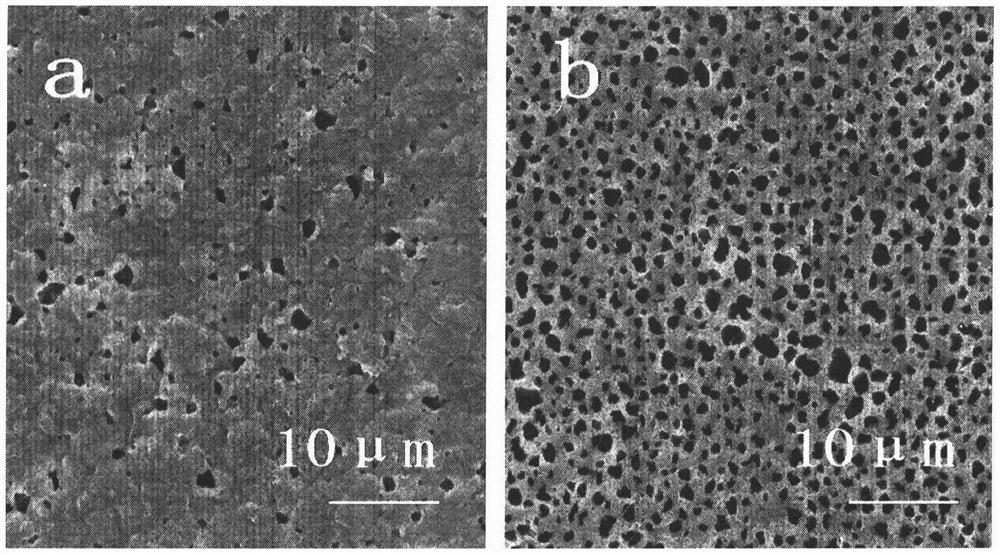

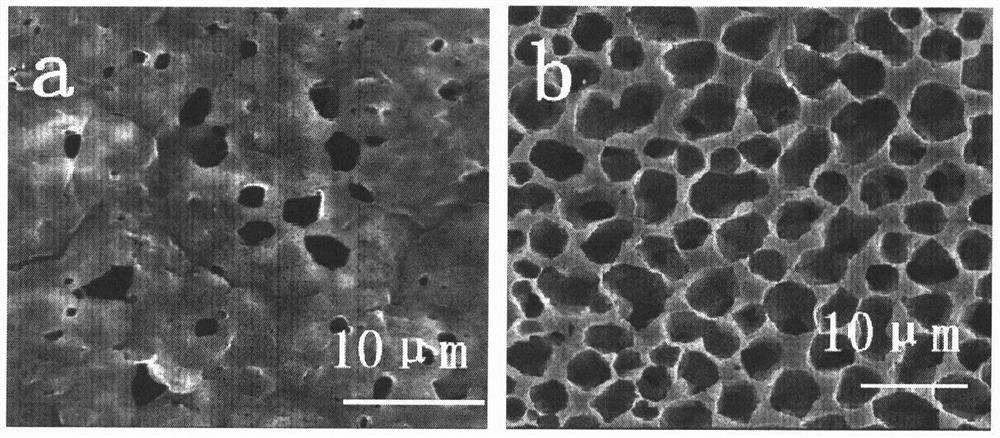

Image

Examples

Embodiment 1

[0033] 1) Synthesis of polyamide 6 composite material: first adopt "one pot method", add 3g caprolactam and 27g 6-aminocaproic acid as reaction monomers in a four-necked flask, add 0.5wt% of dried graphene oxide, After heating and melting, stir mechanically to disperse evenly, program temperature rise to 220°C, and react at a constant temperature for 2 hours; then raise the temperature to 260°C, react at a constant temperature for 8 hours, and stop the reaction; quickly pour out the polymerization product from the reaction container, and cool to obtain a composite material .

[0034] 2) Prepare the casting solution: cut the above composite material into small pieces with diagonal pliers, cook in pure water, and dry the product in a vacuum oven to constant weight. Take an appropriate amount of the above-mentioned raw material slices and dissolve them in formic acid solution to prepare a 20wt% casting solution, then add 9wt% pore-forming agent lithium chloride, stir magnetically...

Embodiment 2~6

[0056] Its preparation process is basically the same as Example 1, the only difference is: change the concentration of GO in step 2).

[0057] The following table is the specific implementation scheme of embodiment 2~5

[0058]

Embodiment 7~10

[0060] The preparation process is basically the same as that of Example 1, except that the concentration of the pore-forming agent in step 2) is changed.

[0061]

[0062]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com