High-performance multifunctional strain sensor material with stable interface as well as preparation method and application of high-performance multifunctional strain sensor material

A strain sensor, high-performance technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, coating, etc., can solve the problems of poor stability, small deformation of crack structure particle layer, poor repeatability of reciprocating deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

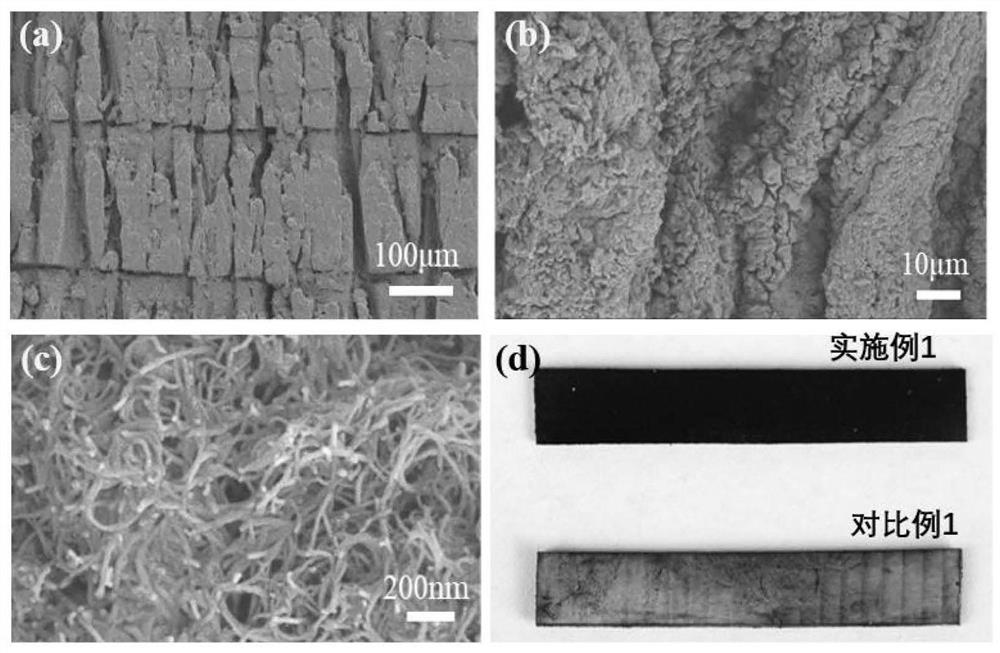

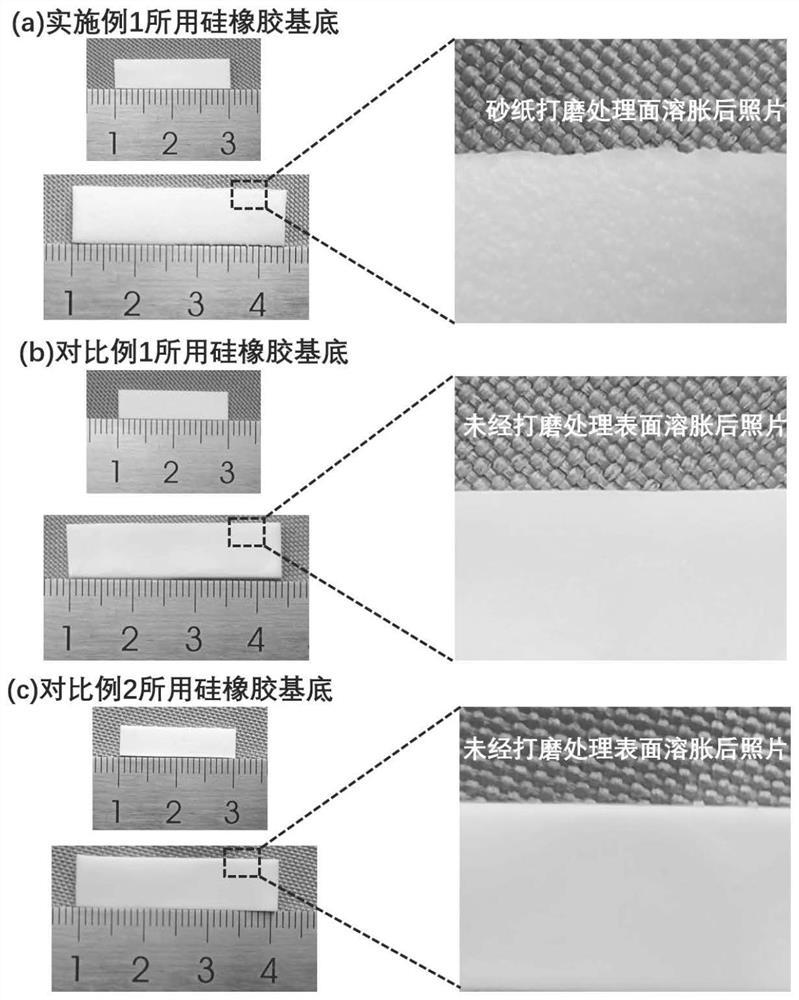

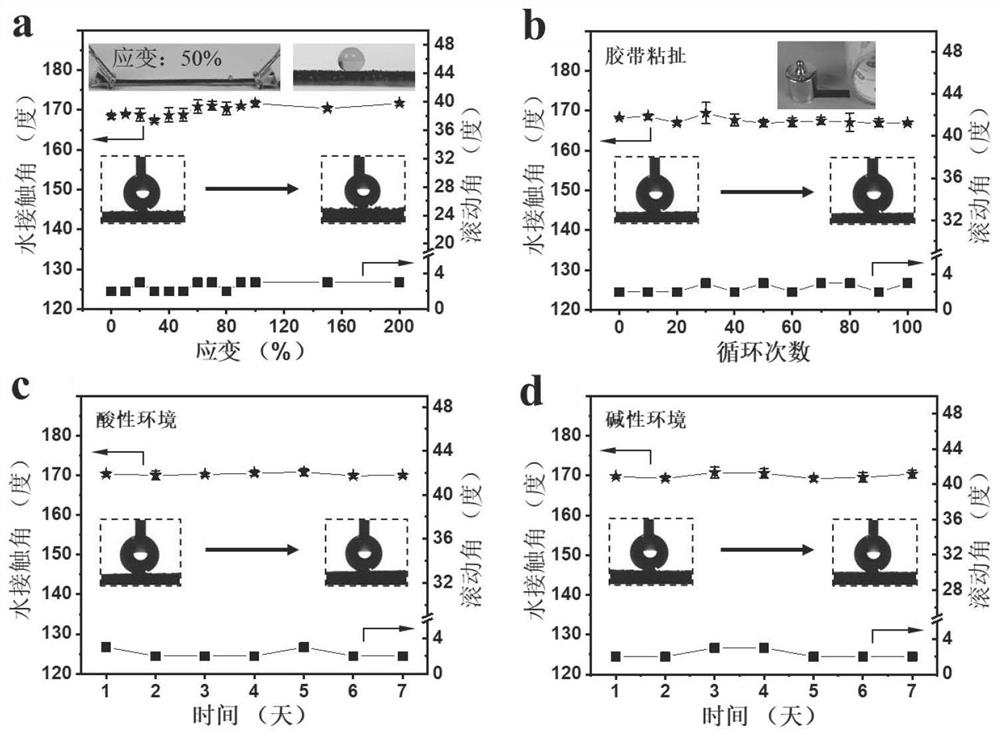

Embodiment 1

[0064] (1) 100g of hydroxyl-terminated polydimethylsiloxane (107 silicone oil) with a viscosity of 10000mPa·s, 30g of hydroxyl-terminated polydimethylsiloxane (107 silicone oil) with a viscosity of 8000mPa·s, silane-modified silica Put 60g into DLH-5L experimental power mixer in turn and stir, heat at 140°C, vacuumize and dehydrate for 2h; after cooling to room temperature, add 6.5g aminopropyltriethoxysilane, 13g vinyltrimethoxysilane, 1.3g Isopropyl titanate and 55 g of silane-modified silicon dioxide were uniformly stirred and mixed under a vacuum condition of -0.09 MPa to obtain a silicone elastomer raw material and sealed for storage. Add 1g of silicone elastomer raw material to 7ml of organic solvent n-hexane and fully dissolve it by stirring to obtain a silicone elastomer raw material solution; then pour it into a polytetrafluoroethylene mold and leave it at room temperature for 12 hours to obtain a surface with a film thickness of 400 μm Initially cured flexible silico...

Embodiment 2

[0070] (1) Put 100g of hydroxyl-terminated polydimethylsiloxane (107 silicone oil) with a viscosity of 10000mPa·s, 70g of hydroxyl-terminated polydimethylsiloxane with a viscosity of 50000mPa·s, and 30g of silane-modified silica into DLH in sequence -In a 5L experimental power mixer, heat at 140°C, vacuumize and dehydrate for 2 hours; after cooling to room temperature, add 8.5g glycidoxypropyltrimethoxysilane, 23.5g vinyltrimethoxysilane, 0.85g titanic acid Ethyl ester and 55g of silicon dioxide were stirred and mixed uniformly under the vacuum condition of -0.09MPa to obtain the silicone elastomer raw material and sealed for storage. Add 1g of silicone elastomer raw material into 2ml of tetrahydrofuran and fully dissolve it by stirring to obtain a diluted solution of silicone elastomer raw material; then pour it into a polytetrafluoroethylene mold, and leave it at room temperature for 24 hours to obtain a film thickness of 2000μm. flexible silicone elastomer substrate.

[00...

Embodiment 3

[0076] (1) 150g of hydroxyl-terminated polydimethylsiloxane (107 silicone oil) with a viscosity of 30000mPa·s, 10g of hydroxyl-terminated polydimethylsiloxane (107 silicone oil) with a viscosity of 800mPa·s, silane-modified silica Put 120g into the DLH-5L experimental power mixer in turn, heat at 140°C, vacuumize and dehydrate for 2h; after cooling to room temperature, add 15g of aminopropyltriethoxysilane, 15g of phenyltrimethoxysilane, and 1.5g of cycloalkane titanium dioxide and 60 g of silane-modified silicon dioxide were stirred and mixed uniformly under vacuum conditions of -0.09 MPa to obtain a raw material for organosilicon elastomer. Add the organic silicon elastomer raw material into cyclohexane and fully dissolve it by stirring to obtain the organic silicon elastomer raw material solution; the ratio of the organic silicon elastomer raw material to the solvent is as follows: 1g of organic silicon elastomer is added to every 15ml of organic solvent Raw materials; then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com