Preparation system and method of KR desulfurizer

A preparation system and desulfurizer technology, applied in the field of KR desulfurizer preparation system, can solve the problems of low effective particle size rate, high equipment failure rate, large lime consumption, etc., to reduce economic operation costs, avoid large dust, reduce lime The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

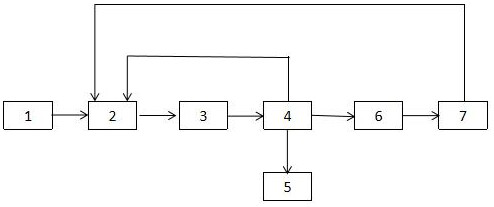

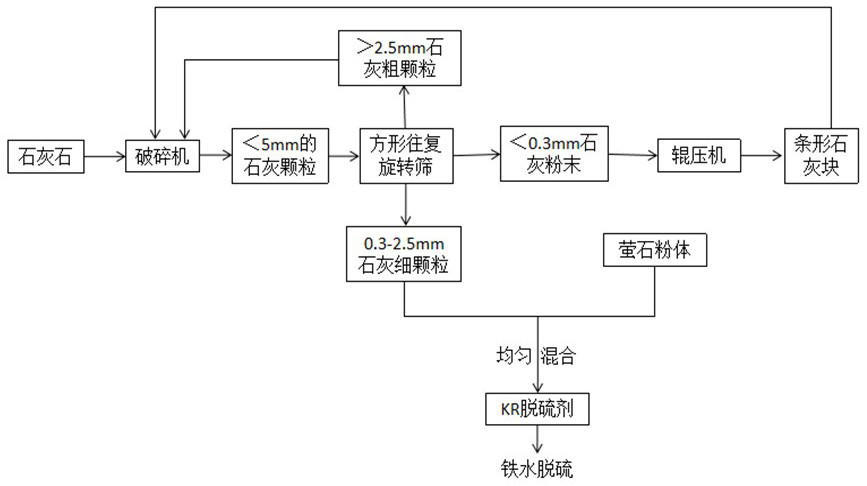

[0022] Such as figure 1 As shown, the present invention provides a preparation system for KR desulfurizer, including a belt conveyor 1, a crusher 2, a bucket elevator 3, a square reciprocating rotary screen 4, a collector 5, a fine powder bin 6 and a roller press 7 , the discharge end of the belt conveyor 1 is connected with the feed port of the crusher 2, the discharge port of the crusher 2 is connected with the feed port of the square reciprocating rotary screen 4 through a bucket elevator 3, and the square reciprocating The first discharge port of the rotary screen 4 is connected with the feed port of the crusher 2, the second discharge port is connected with the feed port of the collector 5, and the third discharge port is connected with the feed port of the fine powder bin 6, so The discharge port of the fine powder bin 6 is connected to the feed port of the roller press 7, and the discharge port of the roller press 7 is connected to the feed port of the crusher 2.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com