Method for improving insulation and voltage resistance of transformer through parylene vapor deposition

A vapor deposition, insulation and withstand voltage technology, applied in transformer/inductor housing, inductance/transformer/magnet manufacturing, transformer/inductor coil/winding/connection, etc., can solve circuit failure, breakdown of transformer and casing, etc. Problems, achieve the effect of improving electrical performance, improving insulation withstand voltage performance, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

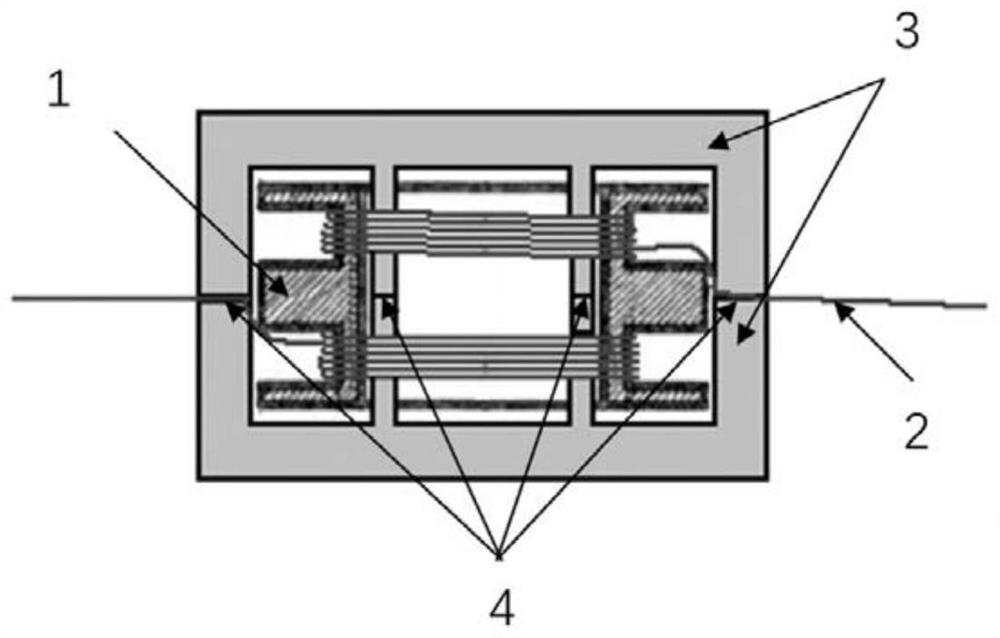

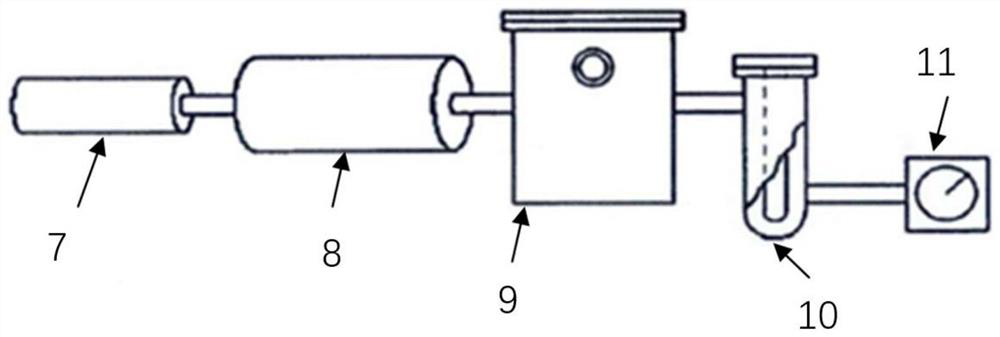

[0046] The transformer is a structure with a magnetic tank and a skeleton, using enameled wire with a diameter of Φ0.08mm, and winding it on the skeleton according to the turn ratio required by the circuit; the insulation withstand voltage requirement of the transformer is that the leakage current between the primary and secondary under AC 2500V does not exceed 0.050mA, and the leakage current does not exceed 1mA at DC 3500V; the circuit needs to be assessed at a high temperature of 150°C during screening. Parylene vapor deposition equipment such as image 3 As shown, it includes a sublimation furnace 7 ; a cracking furnace 8 ; a deposition chamber 9 ; a cold trap 10 ; and a vacuum pump 11 . The specific process steps are: Parylene is heated and gasified in the sublimation furnace 7, and then cracked into free gas phase molecules by the cracking furnace 8 at a high temperature, enters the deposition chamber 9, and passes through the action of the vacuum pump 11 and the cold tr...

Embodiment 2

[0055] The transformer is a structure with a magnetic tank and a skeleton, using enameled wire with a wire diameter of Φ0.08mm, and winding it on the skeleton according to the required turn ratio of the circuit; the insulation withstand voltage requirement of the transformer is that the leakage current between the primary and secondary under AC 1500V should not exceed 1mA, and the leakage current does not exceed 1mA at DC2000V; the temperature of the circuit does not exceed 125°C during screening and assessment and subsequent service.

[0056] (1) The winding is firstly pretreated, that is, the plasma cleaning equipment is used to bombard the surface of the winding with Ar plasma to improve the surface activity of the winding, which helps to strengthen the adhesion of the film layer on the surface of the winding.

[0057] (2) The windings after the pretreatment are placed in the Parylene vapor deposition equipment for film layer preparation, and the batch windings are processed...

Embodiment 3

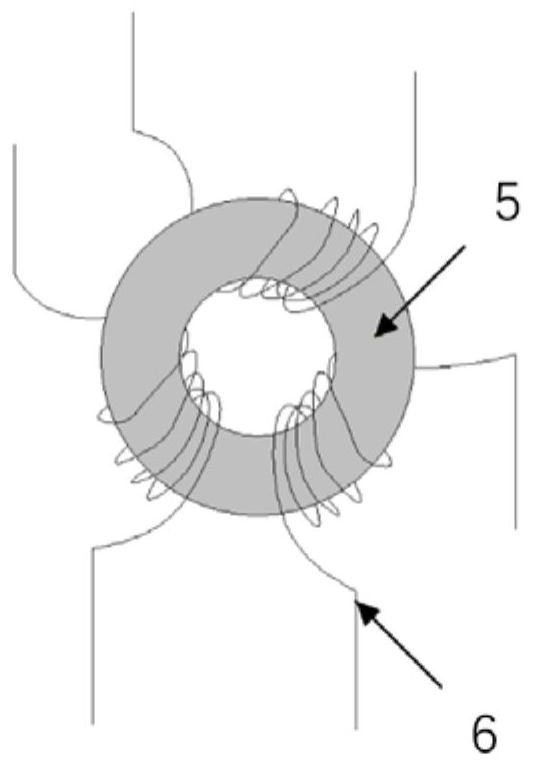

[0064] The transformer is a magnetic core plus enameled wire winding structure, using enameled wire with a wire diameter of Φ0.15mm, which is wound on the magnetic core according to the required turn ratio of the circuit; the insulation withstand voltage requirement of the transformer is the leakage current between the primary and secondary at AC 2000V No more than 1mA, and the leakage current does not exceed 1mA at DC 2800V; the temperature of the circuit is 150°C during screening and assessment and subsequent service.

[0065] (1) The magnetic core is firstly pretreated, that is, the surface activity of the magnetic core is improved by using the plasma cleaning equipment to bombard the surface of the magnetic core, which helps to strengthen the adhesion of the film layer on the surface of the magnetic core.

[0066] (2) After the pretreatment, the magnetic cores are placed in the Parylene vapor deposition equipment for film layer preparation, and the batch magnetic cores are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com