Environment-friendly and efficient special electric appliance composite cleaning agent and preparation method thereof

A compound cleaning agent and circuit board cleaning agent technology, which is applied in the direction of chemical instruments and methods, preparation of detergent mixture compositions, non-surface active cleaning solvents, etc., can solve the problem of dampness of circuit boards, affecting the use of circuit boards, and syncope, etc. problem, to achieve the effect of increasing insulation withstand voltage performance, simple and obvious use effect, and good withstand voltage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

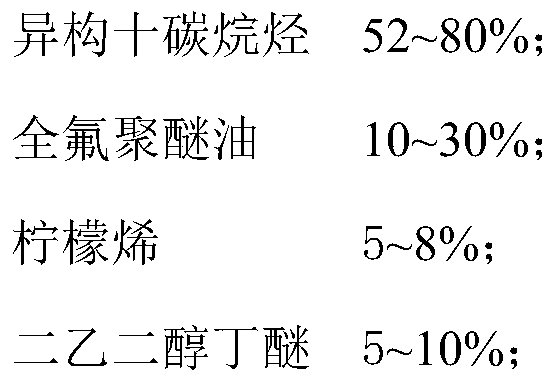

[0047] An environment-friendly and efficient compound cleaning agent for special electrical appliances. The solvent distillation range, mechanical impurity content and weight ratio of each component selected for the electrical appliance surface cleaning agent are respectively:

[0048]

[0049] The solvent distillation range, mechanical impurity content and weight ratio of each component selected by the circuit board cleaning agent are respectively:

[0050]

[0051] The electrical surface cleaning agent and the circuit board cleaning agent are respectively filled in compartments of the cleaning agent packaging barrel.

[0052] The steps of electrical surface cleaner are:

[0053] (1) Open the special reaction kettle for solvent at normal temperature, and start the reaction kettle with uniform speed and slow stirring to preheat for 5-10 minutes;

[0054] (2) Put the isodecane, perfluoropolyether oil, limonene and alcohol ether solvent into the special solvent reaction k...

Embodiment 2

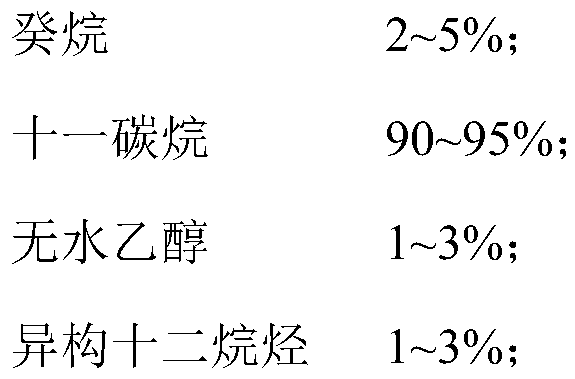

[0062] An environment-friendly and efficient compound cleaning agent for special electrical appliances. The solvent distillation range, mechanical impurity content and weight ratio of each component selected for the electrical appliance surface cleaning agent are respectively:

[0063]

[0064] The solvent distillation range, mechanical impurity content and weight ratio of each component selected by the electric board cleaning agent are respectively:

[0065]

[0066] The steps of electrical surface cleaner are:

[0067] (1) Open the special reaction kettle for solvent at normal temperature, and start the reaction kettle with uniform speed and slow stirring to preheat for 5-10 minutes;

[0068] (2) Put the isodecane, perfluoropolyether oil, limonene and alcohol ether solvent into the special solvent reaction kettle in sequence according to the ratio at room temperature, and start the reaction kettle to stir slowly at a constant speed for 20-30 minutes (required Cover th...

Embodiment 3

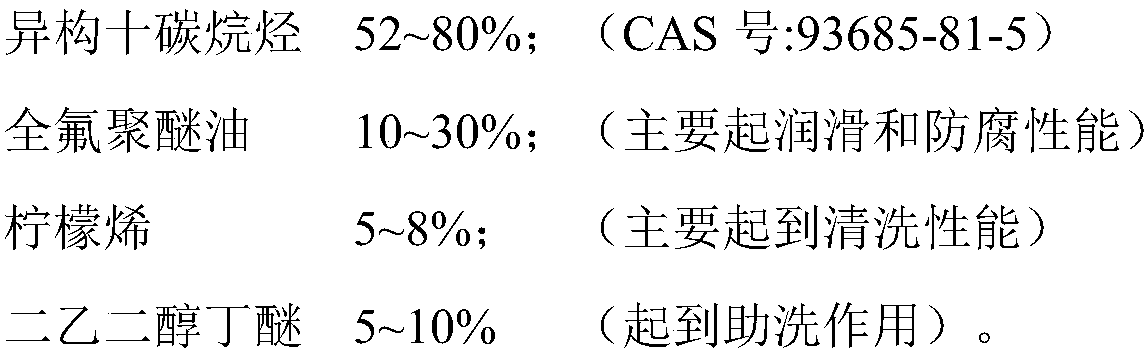

[0076] An environment-friendly and efficient compound cleaning agent for special electrical appliances. The solvent distillation range, mechanical impurity content and weight ratio of each component selected for the electrical appliance surface cleaning agent are respectively:

[0077]

[0078] The solvent distillation range, mechanical impurity content and weight ratio of each component selected by the electric board cleaning agent are respectively:

[0079]

[0080] The electrical surface cleaning agent and the circuit board cleaning agent are respectively filled in compartments of the cleaning agent packaging barrel.

[0081] A kind of preparation method of environment-friendly and high-efficiency special electric appliance composite cleaning agent, the steps of electric appliance surface cleaning agent are:

[0082] (1) Open the special reaction kettle for solvent at normal temperature, and start the reaction kettle with uniform speed and slow stirring to preheat for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com