Heating body and manufacturing process thereof

A manufacturing process and heating element technology, applied in the field of heating element and its manufacturing process, can solve the problems of large volume, complex structure of heating element, low thermal efficiency, etc., and achieve the effect of high heat exchange efficiency, simple structure, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

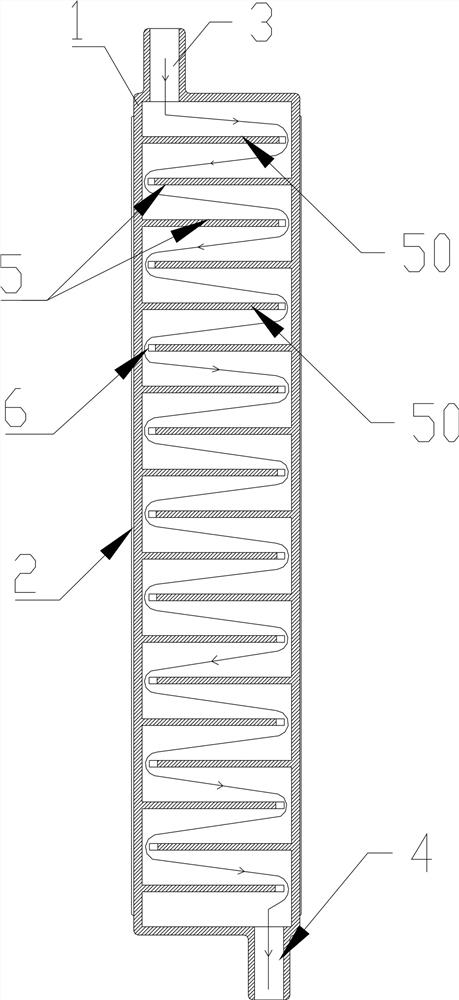

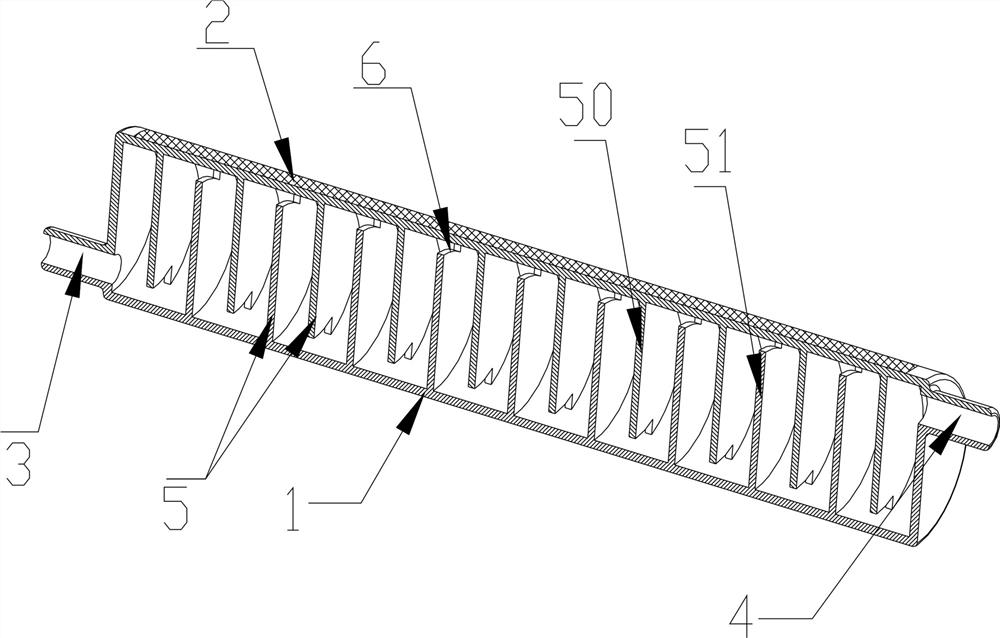

[0032] Such as Figure 1-4 It shows that the present invention discloses a heating body, which includes the heating body blank 1 and heating coating 2 used for heating; The heating body blank body 1 is set with water inlet 3 and water outlet 4; the heating body blank body 1 is set with multiple separators 5, and each partition 5 sets a flowway passage hole 6, 6, 6, 6, 6, 6, 6, 6. The partition plate 5 divides the heating element green body 1 into multiple sections, and after water enters the heating element green body, rapid and sufficient heating can be realized.

[0033] Preferably, the cross-section of the heating element body 1 is circular or elliptical.

[0034] The present invention has a separator in the heating body blank, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com