Two-dimensional material, two-dimensional material alloy and two-dimensional material heterojunction preparation method

A two-dimensional material and heterojunction technology, which is applied in the field of preparation of two-dimensional transition metal chalcogenides, can solve the problems of poor controllability of two-dimensional material growth, poor controllability of two-dimensional material layers, and single crystal quality of two-dimensional materials. To improve controllability and repeatability, realize controllability and high controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1, the two-dimensional material is single-layer or multi-layer MoS 2 controllable preparation method.

[0063] (1) Preparation of MoO with different thicknesses by thermal evaporation 3 Films as Precursor Films:

[0064] In SiO 2 / Si substrate, that is, the surface layer is coated with 300nm SiO 2 layer of MoO on silicon wafers by thermal evaporation method 3 Thin film, set the thermal evaporation current to about 30A, in the SiO 2 Generate MoO on layer 3 The film deposition rate is Four different thicknesses of MoO can be arbitrarily selected within the range of 1-100nm 3 Thin films to grow monolayer or multilayer MoS 2 , in this example, MoO is obtained respectively 3 MoO with film thickness of 5nm, 30nm, 74nm, 100nm 3 / SiO 2 / Si.

[0065] (2) MoS grown by chemical vapor deposition 2 ;

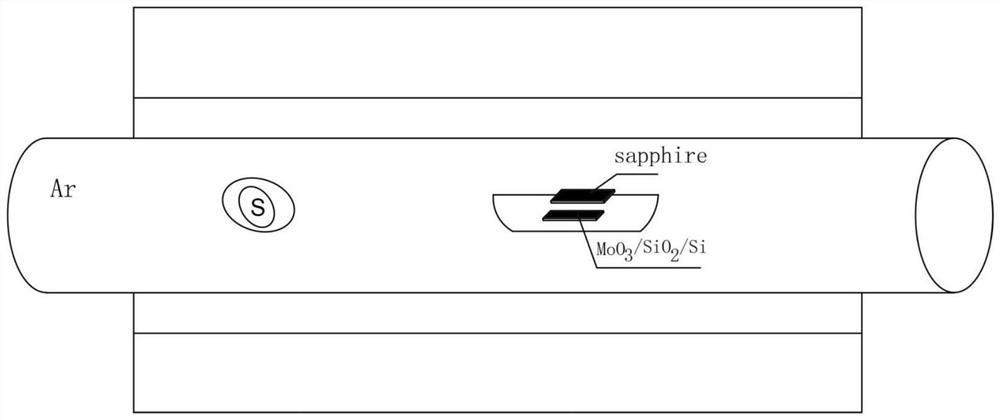

[0066] (2.1) will be coated with MoO 3 thin film MoO 3 / SiO 2 / Si and sapphire substrates are placed in the first evaporation boat, which contains MoO 3...

Embodiment 2

[0072] Embodiment 2, the two-dimensional material is a single layer of WS 2 controllable preparation method.

[0073] (1) Preparation of 30nm WO by thermal evaporation 3 Films as Precursor Films:

[0074] In SiO 2 / Si substrate, that is, the surface layer is coated with 300nm SiO 2 Layers prepared on silicon wafers 3 thin film, set the thermal evaporation current to about 60A, the SiO 2 Generate WO on layer 3 The film deposition rate is Choose to generate WO with a thickness of 30nm 3 , forming WO 3 / SiO 2 / Si to grow monolayer WS 2 .

[0075] (2) Chemical vapor deposition growth WS 2 :

[0076] WO with a film thickness of 30 nm 3 / SiO 2 / Si and sapphire substrates are placed in the first evaporation boat, wherein the MoO 3 The thin film and the sapphire substrate were placed face to face with a distance of 1 mm; the sulfur powder was placed in the second evaporation boat, and the first evaporation boat and the second evaporation boat were respectively placed ...

Embodiment 3

[0077] Embodiment three, the two-dimensional material is Bi 2 S 3 A method for the controllable preparation of nanowires.

[0078] (1) Preparation of 30nm Bi by thermal evaporation 2 o 3 Films as Precursor Films:

[0079] In SiO 2 / Si substrate, that is, the surface layer is coated with 300nm SiO 2 Bi layer prepared on silicon wafer 2 o 3 thin film, set the thermal evaporation current to about 40A, the SiO 2 Generate WO on layer 3 The film deposition rate is Choose Bi 2 o 3 Bi with a film thickness of 30 nm 2 o 3 / SiO 2 / Si to grow Bi 2 S 3 .

[0080] (2) Bi grown by chemical vapor deposition 2 S 3 :

[0081] Bi film with a thickness of 30 nm 2 o 3 / SiO 2 / Si and the sapphire substrate are placed in the first evaporation boat, wherein the Bi 2 o 3 The thin film and the sapphire substrate are placed face to face with a distance of 1mm, the sulfur powder is placed in the second evaporation boat, and the first evaporation boat and the second evaporation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com