Adhesive tape coating liquid composition, adhesive tape coating liquid, adhesive tape and preparation method of adhesive tape

The technology of a composition and coating liquid is applied in the field of tape coating liquid, tape and its preparation, tape coating liquid composition and preparation field, and can solve the problems of LCP destruction, residual glue, disappearance of antistatic effect of tape, etc., To achieve good high temperature resistance, good antistatic effect, high efficiency antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

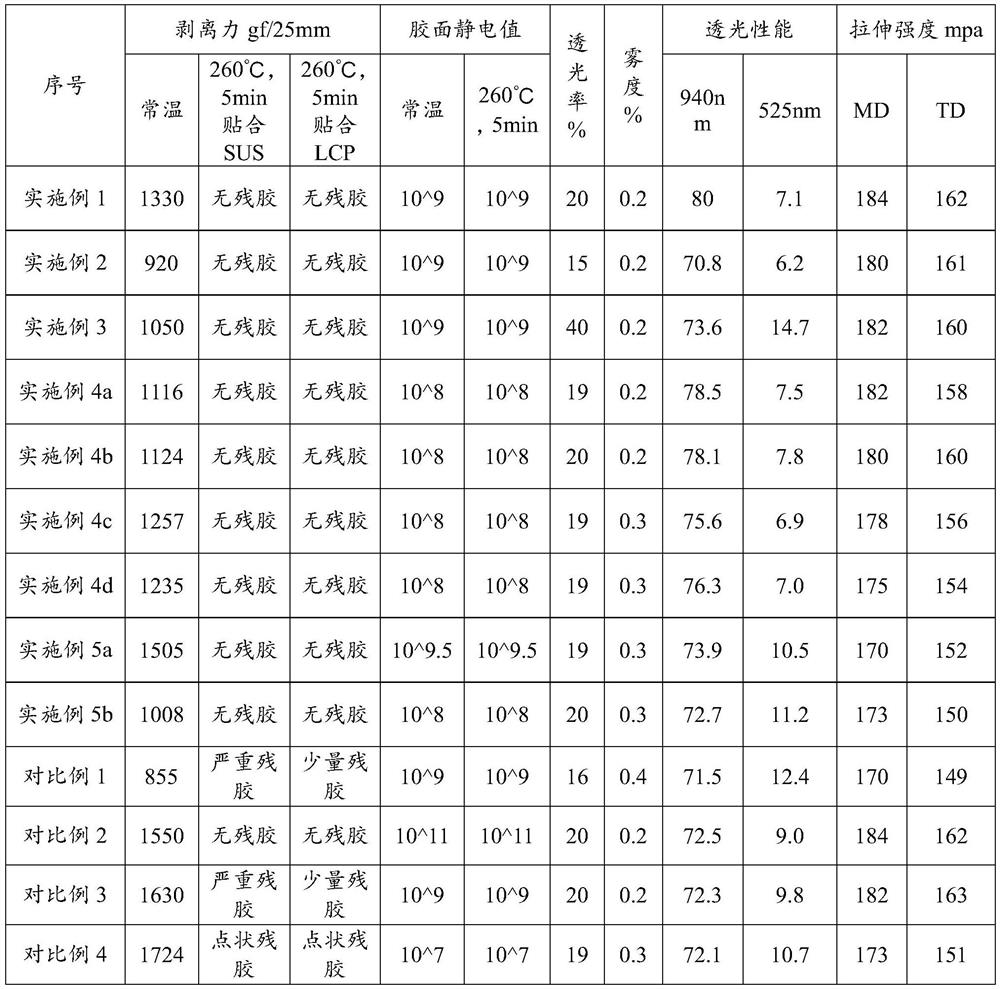

Examples

preparation example 1

[0085] Preparation example 1 prepares polyacrylic acid resin

[0086] (1) Prepare raw materials

[0087] Soft monomer: butyl acrylate, 80 parts by weight;

[0088]Hard monomer: vinyl acetate, 2 parts by weight; Methyl acrylate, 4 parts by weight; Methyl methacrylate, 6 parts by weight;

[0089] Cross-linking monomer: acrylic acid, 8 parts by weight;

[0090] Initiator: azobisisobutyronitrile, 0.4 parts by weight;

[0091] Solvent: ethyl acetate, 130 parts by weight.

[0092] (2) Add the soft monomer, hard monomer and cross-linking monomer in step (1) into the reaction kettle according to the formula, and pass in an inert gas, and heat to 60 ° C for 1 hour; first add 0.2 parts by weight of the initiator First react at 65° C. for 4 hours, then add 0.2 parts by weight of an initiator and react for another 4 hours, and finally add a solvent to obtain a polyacrylic acid resin with a solid content of 30%.

preparation example 2

[0093] Preparation example 2 prepares polyacrylic acid resin

[0094] Carry out with reference to the method of Preparation Example 1, the difference is that the contents of the three monomers are changed. Wherein, soft monomer, 90 parts by weight; Hard monomer, 5 parts by weight; Cross-linking monomer, 5 parts by weight; Keep the type of monomer and the internal ratio constant (for example, the ratio of three components in the hard monomer is different. change, only the total amount is changed).

preparation example 3

[0095] Preparation example 3 prepares polyacrylic acid resin

[0096] (1) Prepare raw materials

[0097] Soft monomer: butyl acrylate, 70 parts by weight;

[0098] Hard monomer: vinyl acetate, 3 parts by weight; Methyl acrylate, 4 parts by weight; Methyl methacrylate, 10 parts by weight;

[0099] Cross-linking monomer: acrylic acid, 13 parts by weight;

[0100] Initiator: azobisisobutyronitrile, 0.4 parts by weight;

[0101] Solvent: ethyl acetate, 130 parts by weight.

[0102] (2) Add the soft monomer, hard monomer and cross-linking monomer in step (1) into the reaction kettle according to the formula, and pass in an inert gas, and heat to 60 ° C for 1 hour; first add 0.2 parts by weight of the initiator First react at 65° C. for 4 hours, then add 0.2 parts by weight of an initiator and react for another 4 hours, and finally add a solvent to obtain a polyacrylic acid resin with a solid content of 27%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com