Three-dimensional graphene-shape memory polymer composite material and preparation method thereof

A memory polymer and composite material technology, applied in the field of shape memory materials, can solve the problems of poor controllability of conductivity, not easy to bend, low efficiency, etc., achieve strong strain resistance and conductivity, fast shape recovery speed, low The effect of stabilizing resistance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

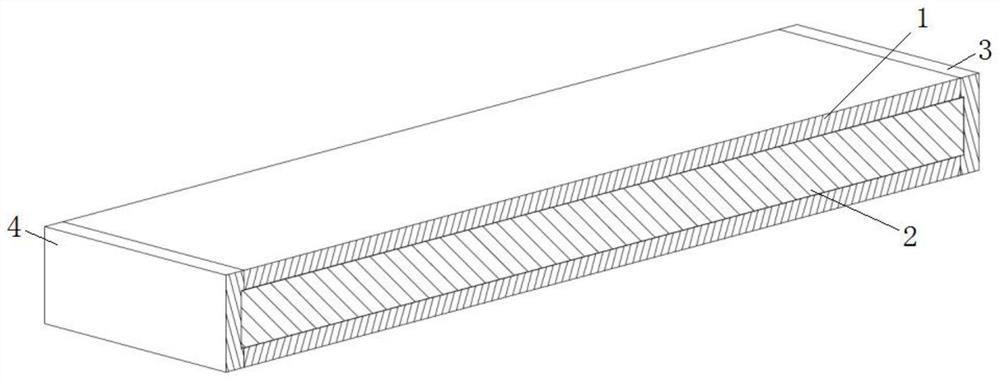

[0048] 1. Three-dimensional graphene-shape memory polymer composites

[0049] 1) The growth of three-dimensional graphene: use the metal foam pressed by 3 layers of nickel foam as the template, adjust the universal testing machine to the compression mode, set the compression force to 4KN, and perform vapor phase chemical deposition growth on the compressed template: growth temperature 1000°C, methane flow rate 30 sccm, hydrogen flow rate 10 sccm, growth time 30 min, and then cooled to room temperature, the three-dimensional graphene grown on the nickel foam template was obtained.

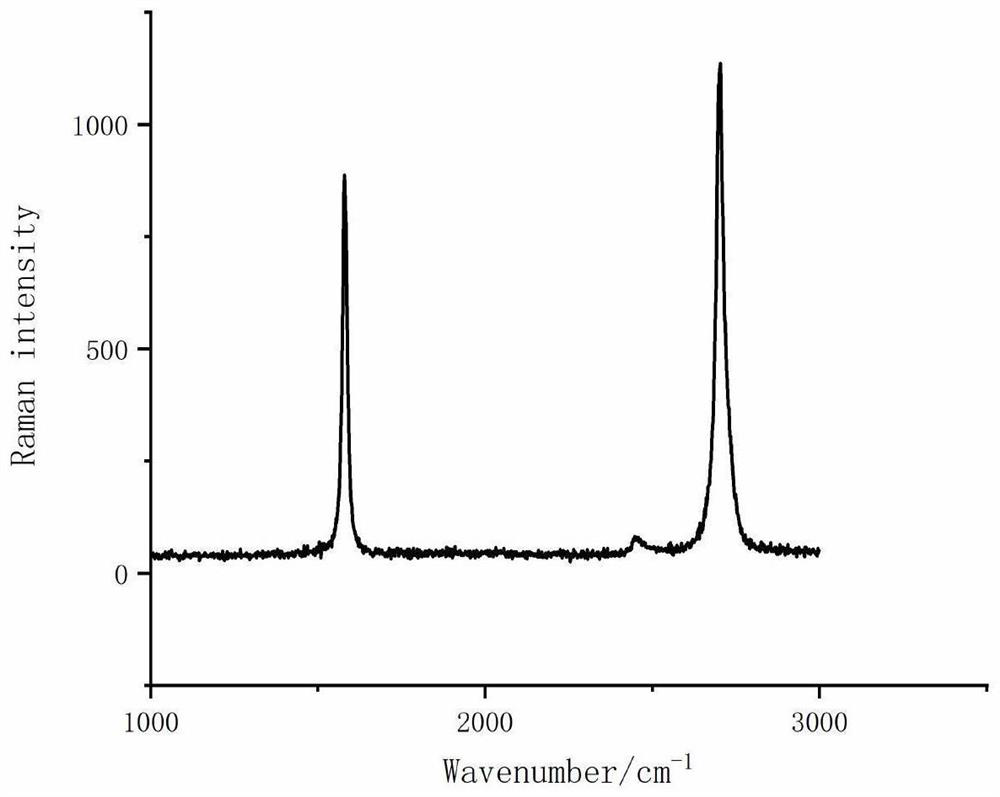

[0050] The growth method is a conventional three-dimensional graphene growth preparation method (as disclosed in the document "J.M. Blocher Jr., Structure / property / process relationships in chemical vapor deposition CVD, J.Vac. Sci. Technol. 11 (1974) 680-686" Reported method), the number of three-dimensional graphene layers obtained in this embodiment is 3-5 layers, and the conductivity is 8s / cm.

...

Embodiment 2

[0064] The basic preparation method of this embodiment is the same as that of Example 1, the difference is that the number of layers of three-dimensional graphene is 3-5 layers, the conductivity is 7.5s / cm, and the etching solution used in this embodiment is 1mol / L super Ammonium sulfate solution, the etching temperature is 75° C., the etching time is 10 h, and the thickness of the memory polymer prepared in this embodiment is 0.2 cm.

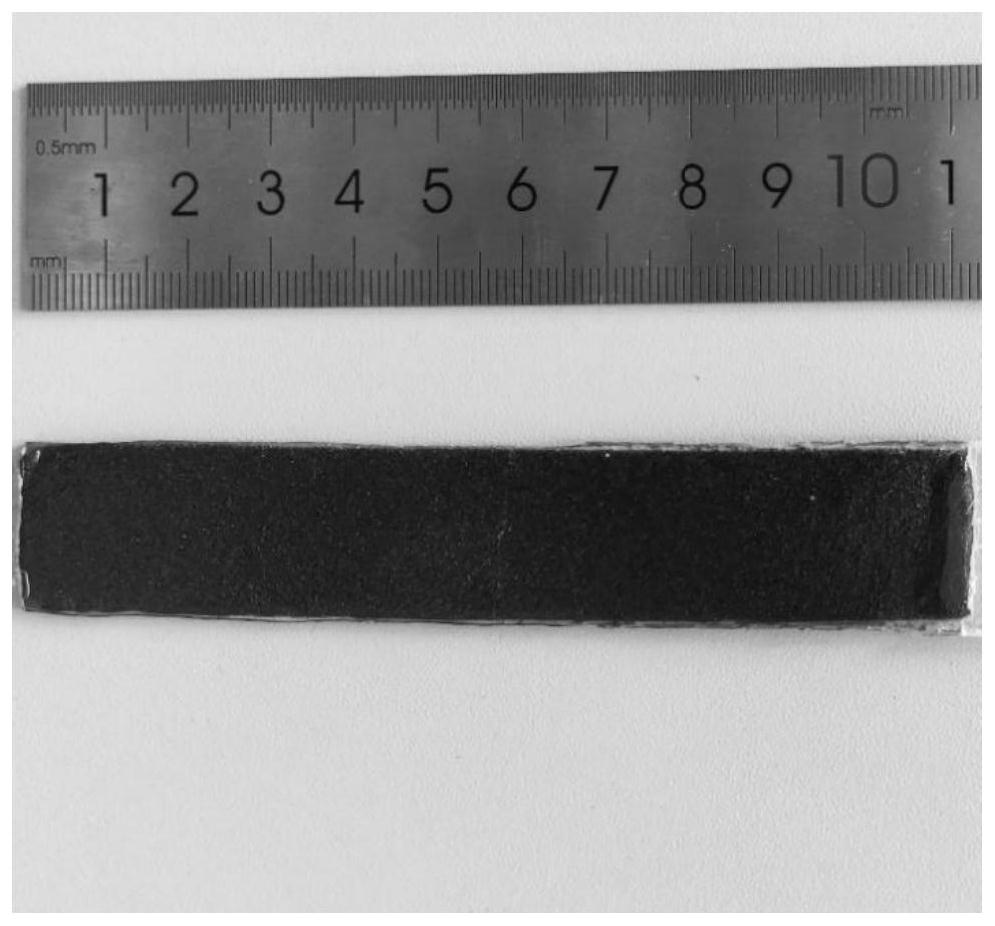

[0065] In this embodiment, the output voltage of the DC stabilized power supply is 20V, and the recovery time is 18S, such as Figure 5 As shown, the shape recovery rate is 100%, and the shape fixation rate is 99.5%.

[0066] Figure 5 Among them, A and B are the photos of the composite material prepared in this example before deformation and after deformation, respectively.

Embodiment 3

[0068] This embodiment is basically the same as Embodiment 1, except that the number of three-dimensional graphene layers is 3-6, the conductivity is 6.9 s / cm, the length of the composite material is 7 cm, and the thickness of the polymer is 0.2 cm.

[0069] In this embodiment, the output voltage of the DC stabilized power supply is 20V, and the recovery time is 8S, such as Image 6 As shown, the shape recovery rate is 100%, and the shape fixation rate is 99.5%.

[0070] Image 6 Among them, A and B are the photos of the composite material prepared in this example before deformation and after deformation, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com