Positive-type thermosensitive computer to plate (CPT) plate

A heat-sensitive and plate material technology, which is applied to photosensitive materials, printing plates, and printing used in optomechanical equipment, can solve the problems of poor thermal sensitivity, achieve good thermal sensitivity, high printing resistance, Printability reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

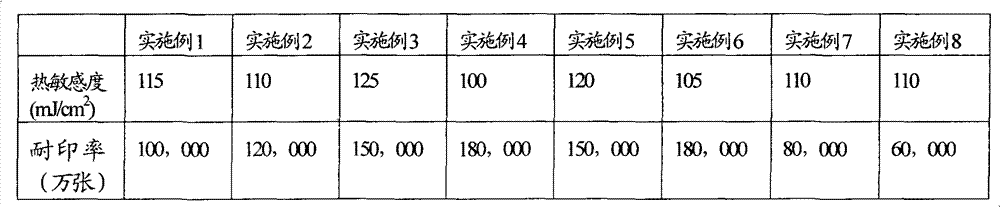

Examples

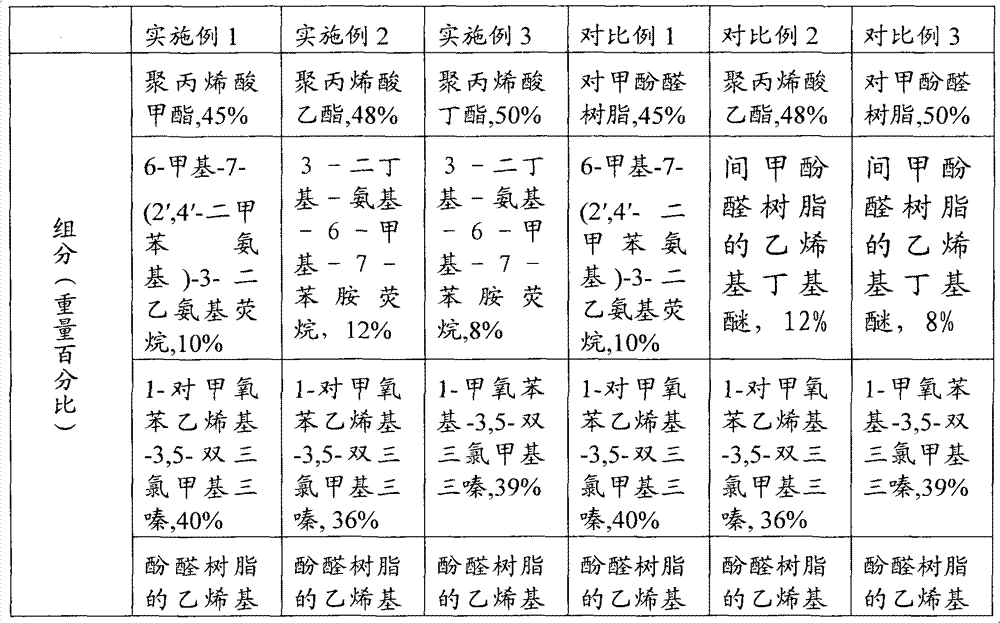

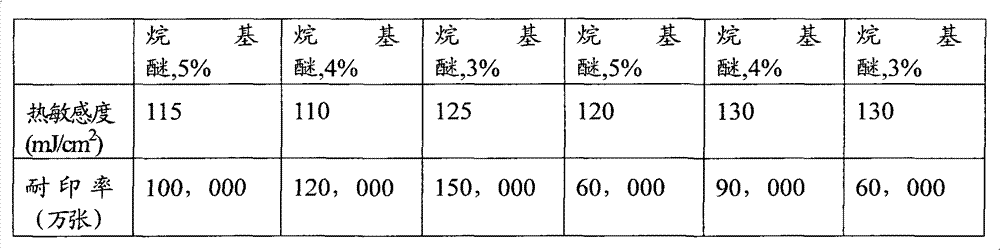

Embodiment 1

[0029] The positive-type heat-sensitive CTP plate material described in this embodiment includes a substrate and a heat-sensitive layer coated on the substrate; the substrate described in this embodiment is an aluminum substrate, and as an optional implementation mode, also The substrate can be selected to be other substrates that can be used for thermal CTP technology;

[0030] The thermosensitive layer is composed of the following components by weight percentage:

[0031] Polymethyl acrylate, 45%;

[0032] 6-methyl-7-(2',4'-xylanilino)-3-diethylaminofluoran, 10%;

[0033] 1-p-methoxystyryl-3,5-bistrichloromethyltriazine, 40%;

[0034] Vinyl alkyl ethers of phenolic resins, 5%.

Embodiment 2

[0036] The positive-type heat-sensitive CTP plate material described in this embodiment includes an aluminum substrate and a heat-sensitive layer coated on the substrate;

[0037] The thermosensitive layer is composed of the following components by weight percentage:

[0038] Polyethylacrylate, 48%;

[0039] 3-Dibutyl-amino-6-methyl-7-anilinofluorane, 12%;

[0040] 1-p-methoxystyryl-3,5-bistrichloromethyltriazine, 36%;

[0041] Vinyl alkyl ethers of phenolic resins, 4%.

Embodiment 3

[0043] The positive-type heat-sensitive CTP plate material described in this embodiment includes an aluminum substrate and a heat-sensitive layer coated on the substrate;

[0044] The thermosensitive layer is composed of the following components by weight percentage:

[0045] Polybutylacrylate, 50%;

[0046] 3-Dibutyl-amino-6-methyl-7-anilinofluorane, 8%;

[0047] 1-methoxyphenyl-3,5-bistrichloromethyltriazine, 38%;

[0048] Vinyl alkyl ethers of phenolic resins, 4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com