Preparation method and application of benzoxazine capable of being rapidly photo-cured, and photo-cured benzoxazine resin

A benzoxazine, light curing technology, applied in organic chemistry, coating, additive processing, etc., to achieve the effects of easy availability of raw materials, environmental protection, and compatibility of process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

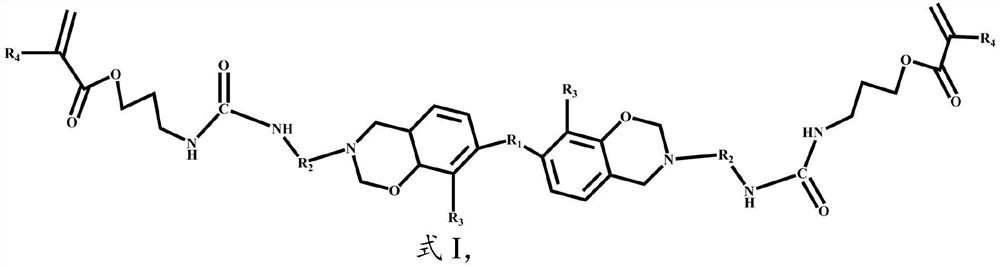

[0046] The present invention also provides a method for preparing the fast photocurable benzoxazine described in the above technical solution, comprising the following steps:

[0047] Mix ethyl acrylic acid isocyanate compound, diamine and solvent to carry out a substitution reaction to obtain a substitution product; the ethyl acrylic acid isocyanate compound is ethyl methacrylate isocyanate or ethyl acrylic acid isocyanate ester;

[0048] Mixing the substitution product, paraformaldehyde and dihydric phenol, and performing a dehydration condensation reaction to obtain a dehydration condensation product;

[0049] The dehydration condensation product is mixed with a precipitating agent to obtain the fast photocurable benzoxazine.

[0050] In the present invention, unless otherwise specified, the raw materials used are all commercially available products in this field.

[0051] In the present invention, ethyl acrylic acid isocyanate compound, diamine and solvent are mixed to c...

Embodiment 1

[0083] At room temperature, add 33.426g of 2,2-bis(4-aminophenyl)hexafluoropropane and 17.067g of ethyl methacrylate isocyanate into 500mL of dimethylformamide, stir for 5 hours, then add 11.42g of bis Phenol A and 9.008g paraformaldehyde, stir well; heat up to 140°C and react for 12 hours; after cooling to room temperature, introduce the reaction liquid into warm water at 60°C, and ultrasonically clean and stir for 1 hour, repeat the lotion process 3 times, Then the light yellow viscous liquid was dried in a vacuum oven at 60° C. for 8 hours, and finally a fast photocurable benzoxazine (P-BOZ-1, structure shown in formula II) was obtained with a yield of 85%.

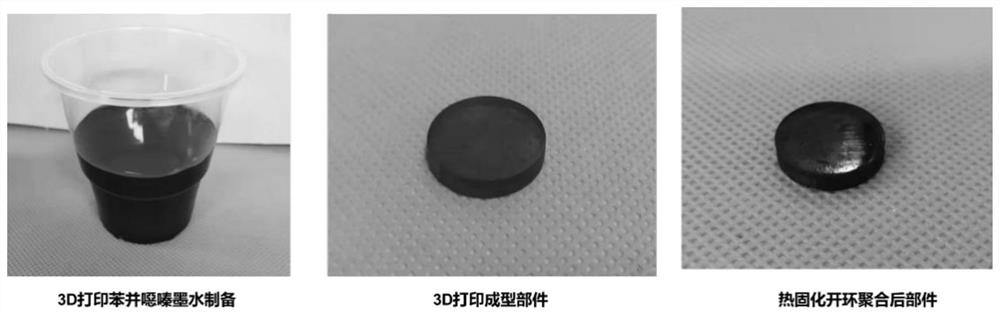

[0084] 70g P-BOZ-1, 10g vinylpyrrolidone, 18g ethoxylated pentaerythritol tetraacrylate and 2g photoinitiator 2,4,6-trimethylbenzoyl-diphenylphosphine oxide (819) were mixed and ball milled Mix and prepare a uniform photosensitive resin, coat the resin on a glass slide, and then perform UV exposure for 30 seconds and c...

Embodiment 2

[0087]At room temperature, add 22.426g 2-(4-aminophenyl)-5-aminobenzimidazole and 17.067g ethyl methacrylate isocyanate to 500mL dimethylpyrrolidone, stir for 6 hours, then add 15.421g alkene Propyl bisphenol A and 9.008g of paraformaldehyde, after being stirred evenly, heated up to 140°C for 12 hours; then, after cooling to room temperature, pour the reaction liquid into 5L of ethanol and water with a volume ratio of 1:20 of 60 Mix in the precipitant at ℃, and ultrasonically clean and stir for 1 hour, repeat the washing process 3 times, then obtain a light yellow viscous liquid and dry it in a vacuum oven at 60 ℃ for 8 hours, and finally obtain the photosensitive benzoxazine intermediate (P-BOZ -2, the structure shown in formula III), the yield is 90%.

[0088] Mix 68g of P-BOZ-2, 5g of vinyl formamide, 25g of trimethylolpropane triacrylate and 2g of photoinitiator dimethoxyacetophenone and mix them by ball milling to prepare a uniform photosensitive resin, and coat the resin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com