Bismuth telluride thermoelectric material based on entropy engineering and preparation method thereof

A thermoelectric material, bismuth telluride technology, applied in the direction of thermoelectric device junction lead-out material, chemical instruments and methods, thermoelectric device manufacturing/processing, etc. Lattice thermal conductivity, enhanced anharmonicity, simple process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

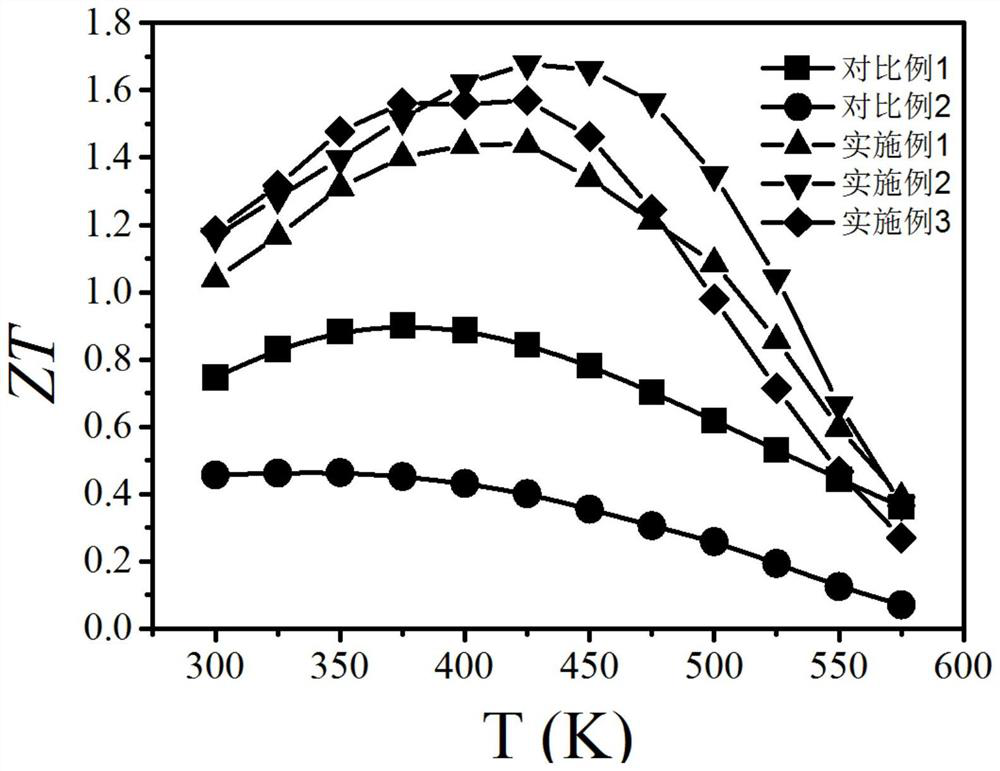

Embodiment 1

[0058] This embodiment provides a bismuth telluride thermoelectric material based on entropy engineering and its preparation method. The preparation method includes the following steps:

[0059] (1) According to the chemical formula Bi 0.97 Ag 0.03 SbT 2The stoichiometric ratio of Se weighs Bi simple substance, Ag simple substance, Sb simple substance, Te simple substance and Se simple substance; wherein, Q is Ag, x=1, y=1, z=0.03; put the weighed raw materials into quartz The tube is sealed and mixed evenly, put into a muffle furnace for smelting, and the master alloy is obtained after cooling;

[0060] Wherein, control the vacuum degree of the sealed quartz tube to be 7×10 -4 Pa; control the heating rate of the smelting to be 5°C / min, the temperature to be 1050°C, and the holding time to be 6h;

[0061] (2) Put the master alloy obtained in step (1) into an agate grinding jar or a stainless steel grinding jar, perform manual grinding for 2 hours, and obtain a sample powde...

Embodiment 2

[0064] This embodiment provides a bismuth telluride thermoelectric material based on entropy engineering and its preparation method. The preparation method includes the following steps:

[0065] (1) According to the chemical formula Bi 0.95 Ag 0.05 SbT 2 The stoichiometric ratio of Se Weigh Bi simple substance, Ag simple substance, Sb simple substance, Te simple substance and Se simple substance; wherein, Q is Ag, x=1, y=1, z=0.05; put the weighed raw materials into quartz The tube is sealed and mixed evenly, put into a muffle furnace for smelting, and the master alloy is obtained after cooling;

[0066] Wherein, control the vacuum degree of the sealed quartz tube to be 7×10 -4 Pa; control the heating rate of the smelting to be 3°C / min, the temperature to be 950°C, and the holding time to be 6h;

[0067] (2) Put the master alloy obtained in step (1) into an agate grinding jar or a stainless steel grinding jar, perform manual grinding for 3 hours, and obtain a sample powder...

Embodiment 3

[0070] This embodiment provides a bismuth telluride thermoelectric material based on entropy engineering and its preparation method. The preparation method includes the following steps:

[0071] (1) According to the chemical formula Bi 0.94 Ag 0.06 SbT 2 The stoichiometric ratio of Se is to weigh Bi simple substance, Ag simple substance, Sb simple substance, Te simple substance and Se simple substance; wherein, Q is Ag, x=1, y=1, z=0.06; put the weighed raw materials into quartz The tube is sealed and mixed evenly, put into a muffle furnace for smelting, and the master alloy is obtained after cooling;

[0072] Wherein, control the vacuum degree of the sealed quartz tube to be 7×10 -4 Pa; control the heating rate of the smelting to be 2°C / min, the temperature to be 850°C, and the holding time to be 6h;

[0073] (2) Put the master alloy obtained in step (1) into an agate grinding jar or a stainless steel grinding jar, perform manual grinding for 2 hours, and obtain a sample ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thermoelectric figure of merit | aaaaa | aaaaa |

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com