Biaxially oriented polyethylene-based film with high surface energy

A polyethylene base film, biaxial stretching technology, applied in the field of polyethylene film, can solve the problem of low surface energy and achieve the effect of reliable bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

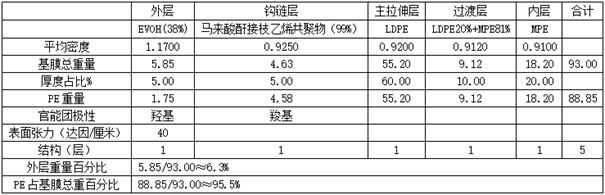

Embodiment 1

[0058]

[0059] The polarity of the functional group (carboxyl group) contained in the hook chain layer is greater than that of the functional group (hydroxyl group) contained in the outer layer;

[0060] The surface tension of the high surface layer is 50 dyne / cm, greater than 38 dyne / cm.

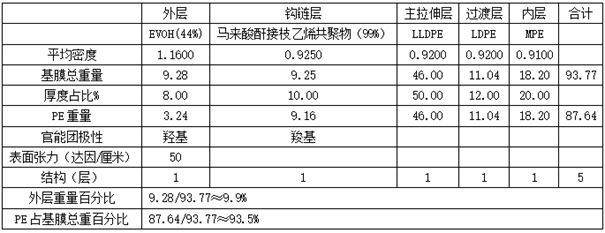

Embodiment 2

[0062]

[0063] The polarity of the functional group (carboxyl group) contained in the hook chain layer is greater than that of the functional group (amide group) contained in the outer layer;

[0064] The surface tension of the high surface layer is 46 dyne / cm, greater than 38 dyne / cm.

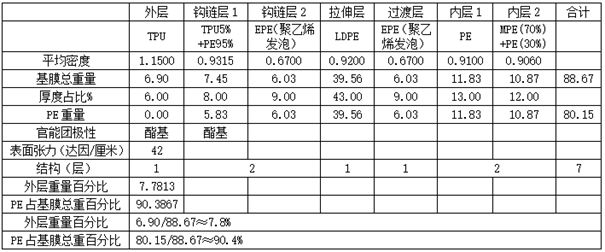

Embodiment 3

[0066]

[0067] The polarity of the functional group (ester group) contained in the hook chain layer is equal to the polarity of the functional group (ester group) contained in the outer layer;

[0068] The surface tension of the high surface layer is 40 dyne / cm, greater than 38 dyne / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com