Equipment and method for preparing high-purity magnesium silicide powder

A magnesium silicide, high-purity technology, applied in chemical instruments and methods, metal silicides, transportation and packaging, etc., can solve the problems of low preparation efficiency, high preparation cost, inability to effectively improve preparation efficiency, and avoid mixing effects. poor, improve the preparation efficiency, increase the convenience of use and the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

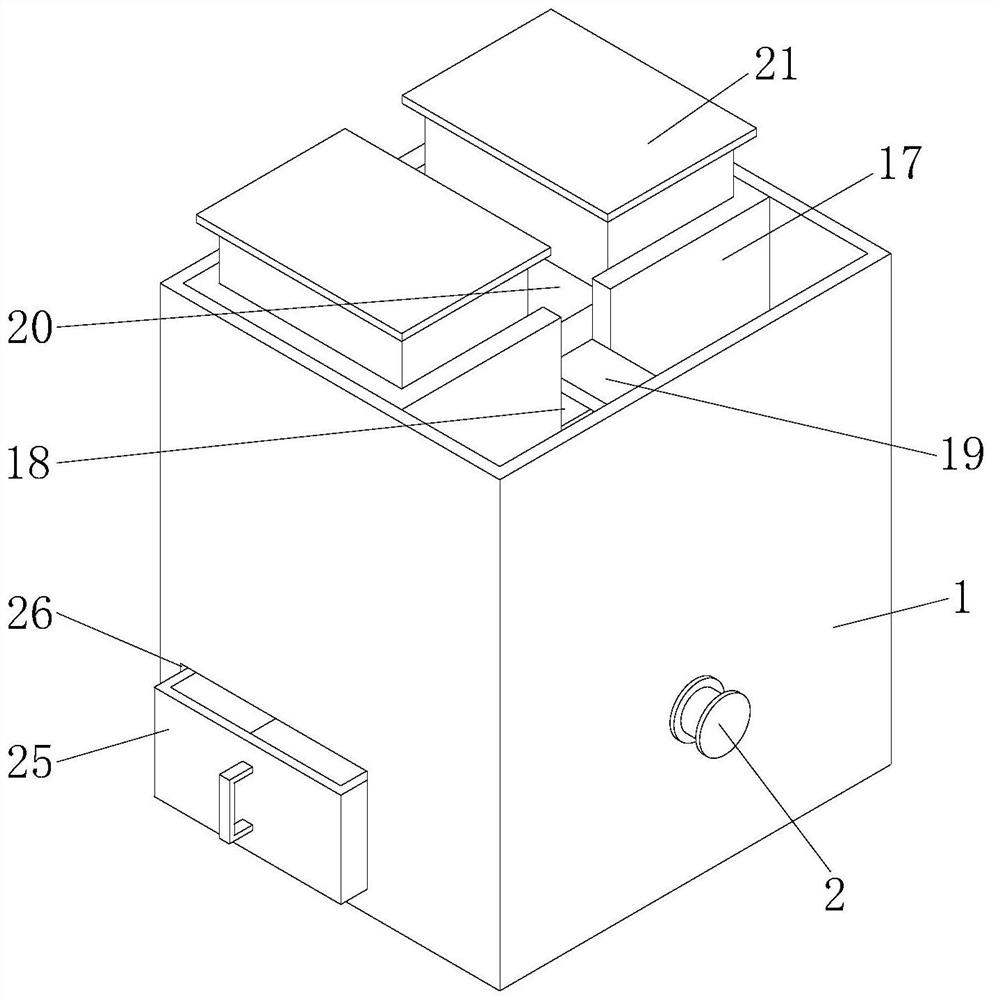

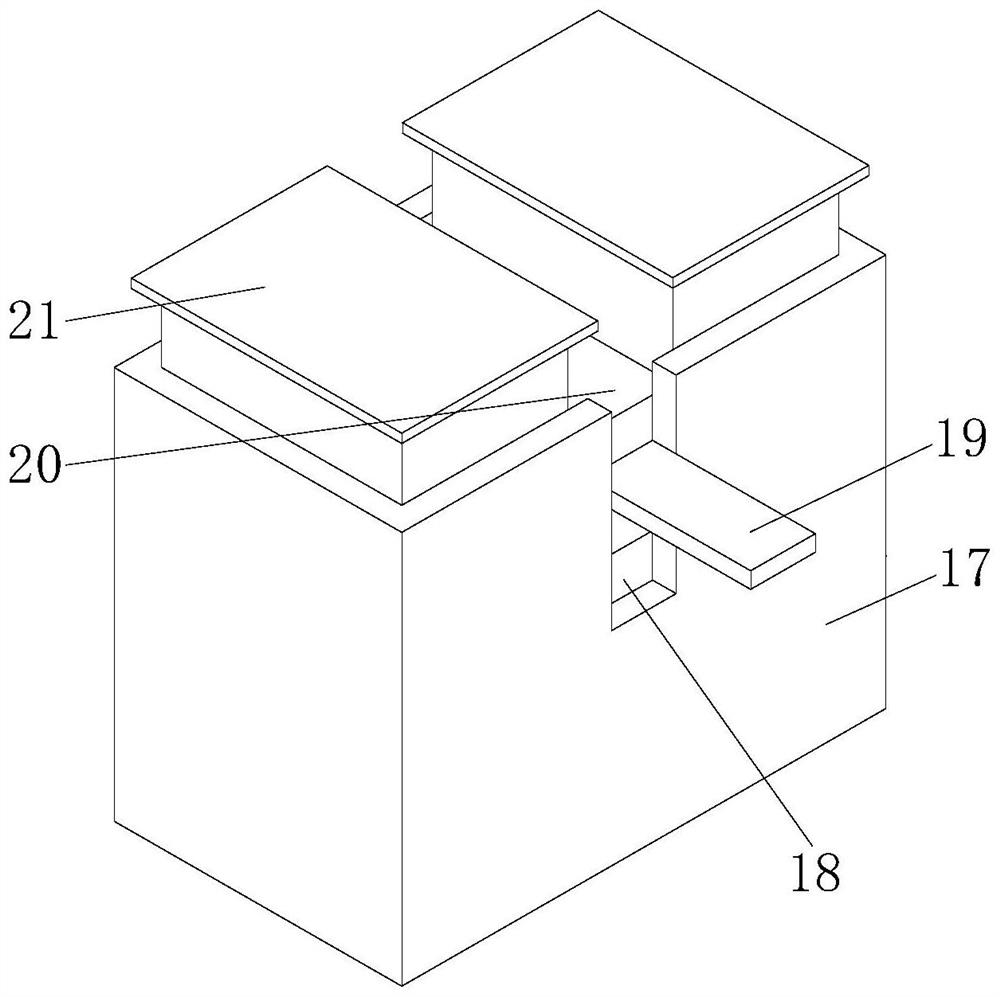

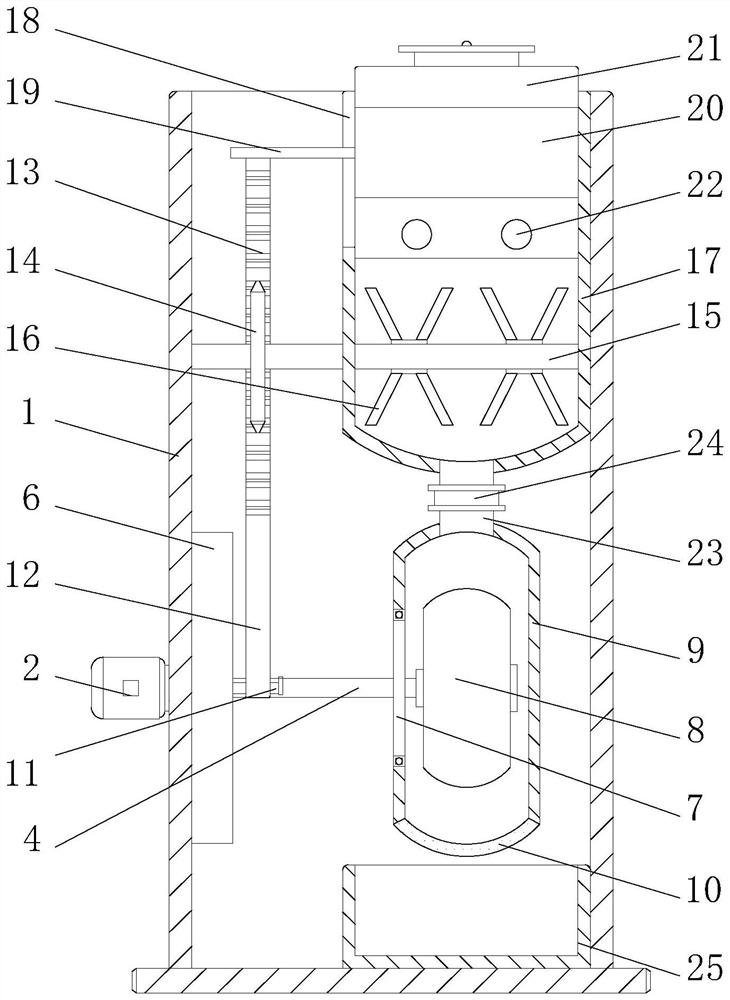

[0041] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

[0042] Such as Figure 1-9 As shown, a method for preparing high-purity magnesium silicide powder includes a device shell 1, a servo motor 2 is welded and fixed on the device shell 1, an connecting plate 3 is welded and fixed on the output shaft of the servo motor 2, and the other end of the connecting plate 3 is Rotationally connected with a fixed shaft 4, the fixed shaft 4 is welded and fixed with a first circular gear 5 and a grinding wheel 8, the first circular gear 5 is meshed with an internal gear 6, and the internal gear 6 and the grinding frame 9 are welded and fixed on the Inside the device housing 1, a protective plate 7 is rotatably connected to the fixed shaft 4.

[0043] Utilizing the interlocking cooperation between the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com