Self-sealing connecting flange joint for double-wall corrugated pipeline

A technology for corrugated pipes and connecting flanges, which is used in hose connection devices, pipe/pipe joints/pipe fittings, flange connections, etc., and can solve problems such as difficult molding, deformation of rubber sealing rings, and difficult construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

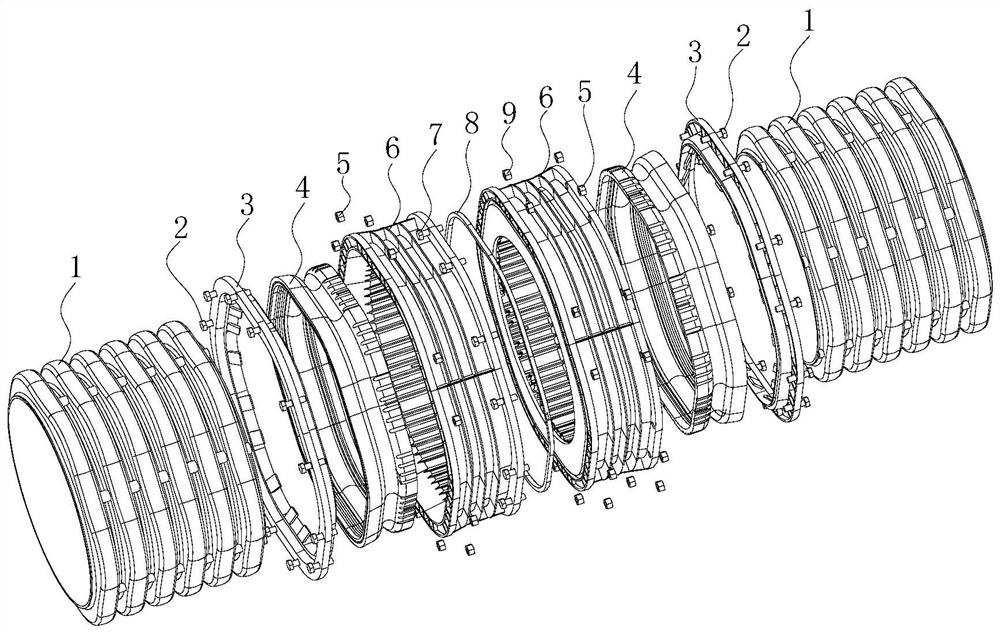

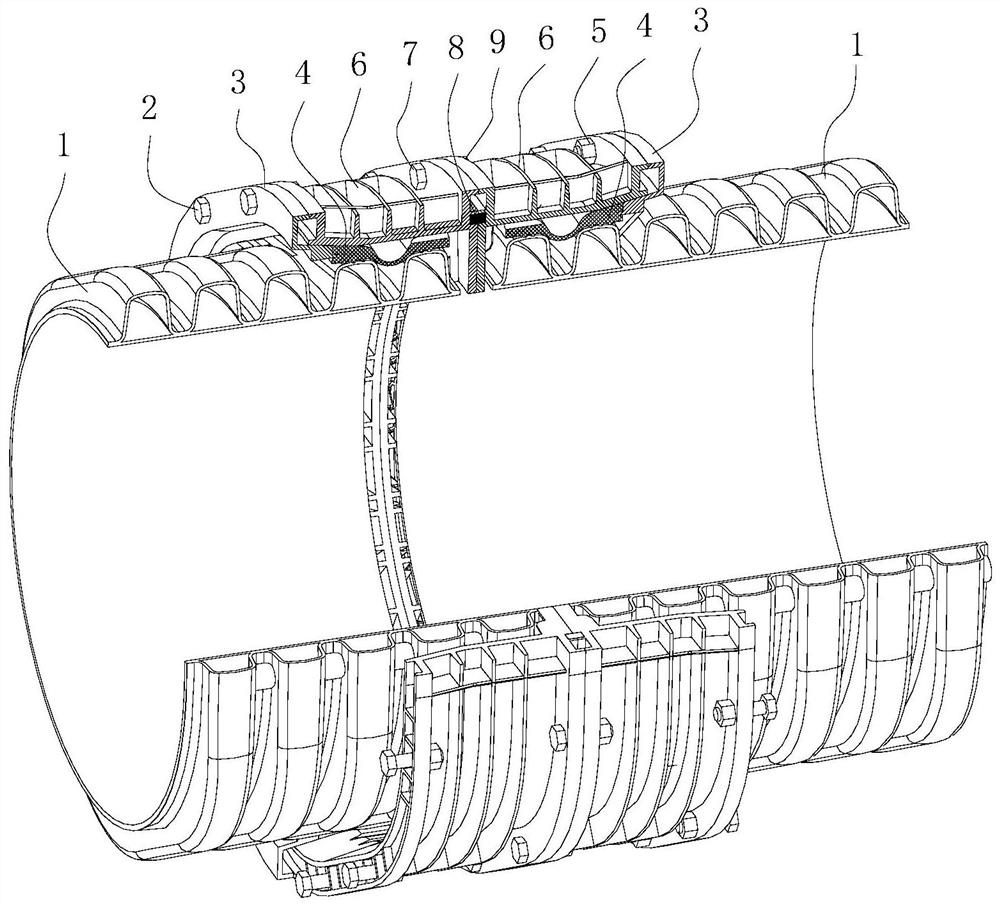

[0029] Embodiment 1 of the present invention: a double-wall corrugated pipe self-sealing connection flange joint, including an annular flange joint housing 6, a sealing ring 4 is arranged inside the flange joint housing 6, and the flange joint housing 6 An anti-off pre-tightening compression ring 3 is provided at the entrance, and the anti-off pre-tightening compression ring 3 fixes the sealing ring 4 through the pre-tightening screw 2 and the nut 5, and a first On the bonding surface 29 , a circumferential groove 27 is provided on the back of the first bonding surface 29 . The silt in the pipe network accumulates in the circumferential groove 27 through the silt flow channel, and the accumulated silt compresses the circumferential groove 27 in a circumferential direction, and the squeezed circumferential groove 27 clings to the plastic double-wall corrugated pipe The side wall of the trough realizes the self-sealing of the axial equal pressure at this position.

[0030] The ...

Embodiment 2

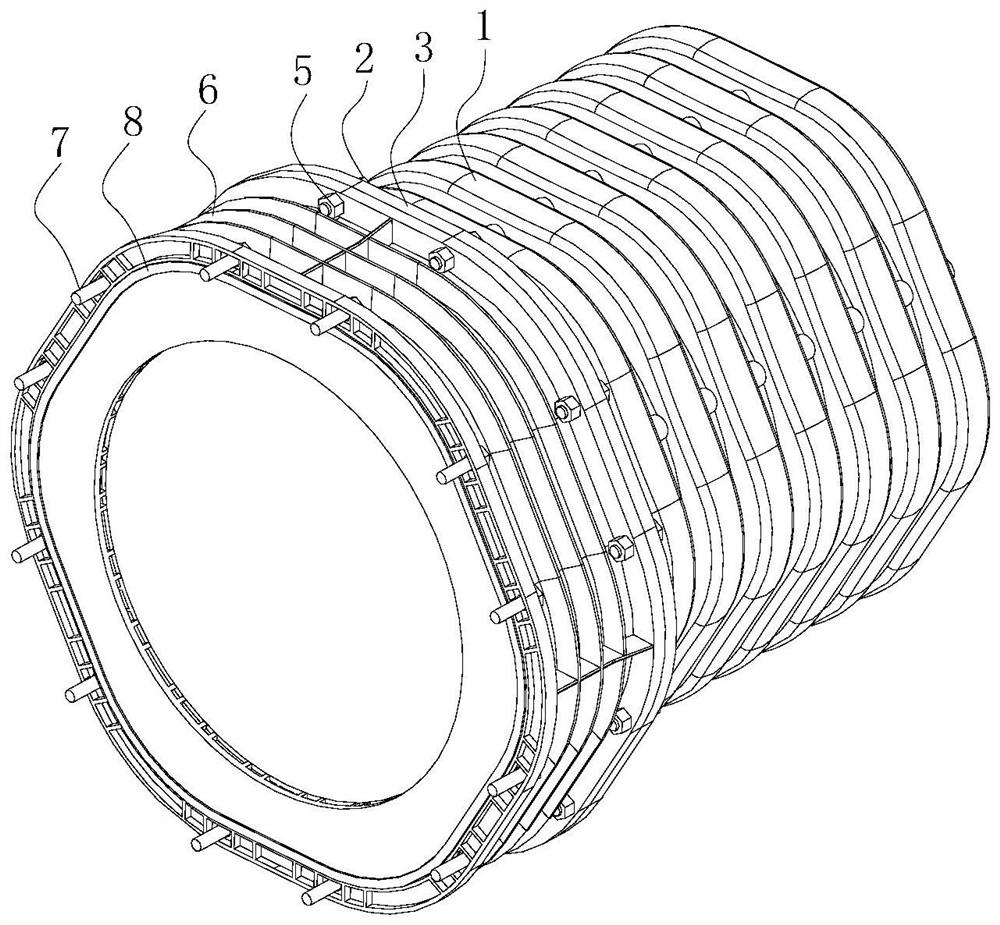

[0044] Embodiment 2: Another preferred solution of the present invention is to adapt to a circular plastic double-wall corrugated pipe. The composition and sealing principle of the joint parts are the same as those described in Embodiment 1 of the present invention. The flange joint housing 6, The sealing ring 4 and the anti-loosening pre-tightening pressure ring 3 are suitable for circular plastic double-wall corrugated pipes in shape, that is, the flange joint housing 6 and the sealing ring 4 are circular cylindrical structures, and the anti-loosening pre-tightening pressure ring 3 is circular ring structure.

[0045] A self-sealing flange joint for double-wall corrugated pipes, including an annular flange joint housing 6, a sealing ring 4 is provided inside the flange joint housing 6, and an anti-slip prevention device is provided at the entrance of the flange joint housing 6. Tighten the compression ring 3, the anti-off pre-tightening compression ring 3 fixes the sealing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com