Scratch-resistant stain-resistant interior wall coating and preparation method thereof

A technology for interior wall coating and stain resistance, applied in coating and other directions, can solve the problems of inconvenient construction and high operation requirements, and achieve the effects of improving scratch resistance, simple production process and convenient coating construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

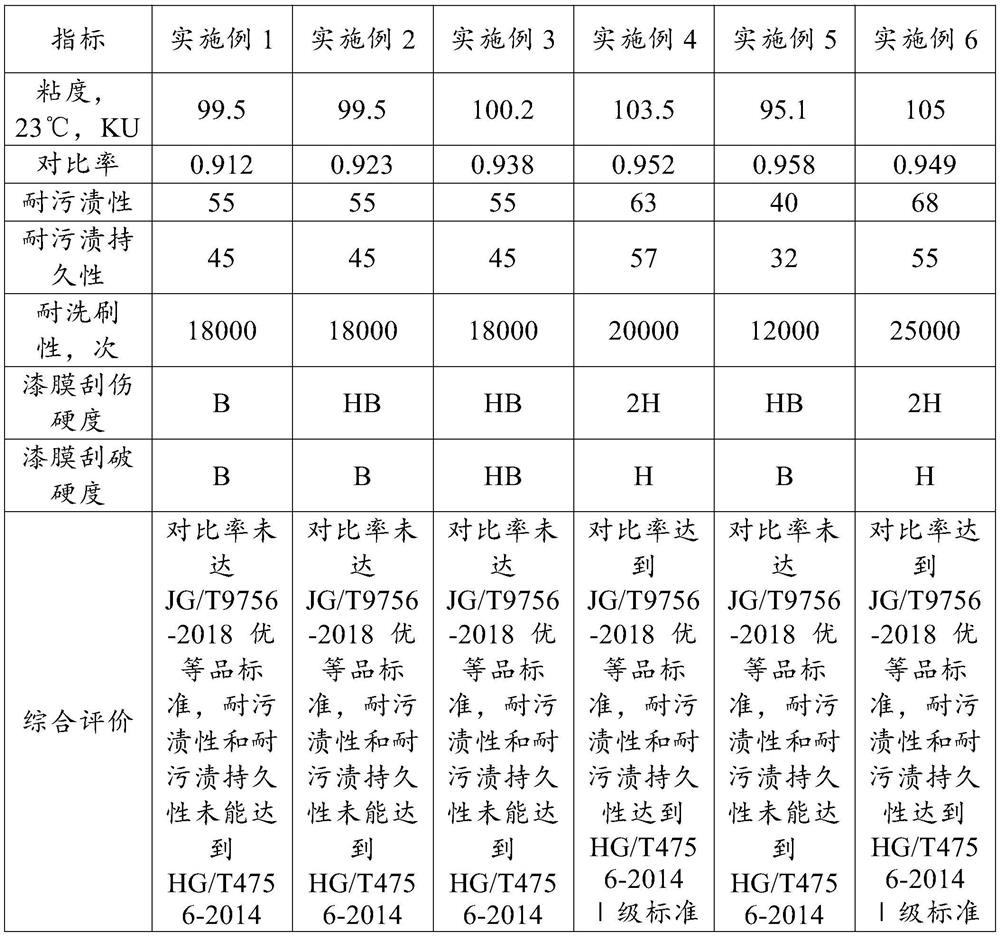

Examples

Embodiment 1~6

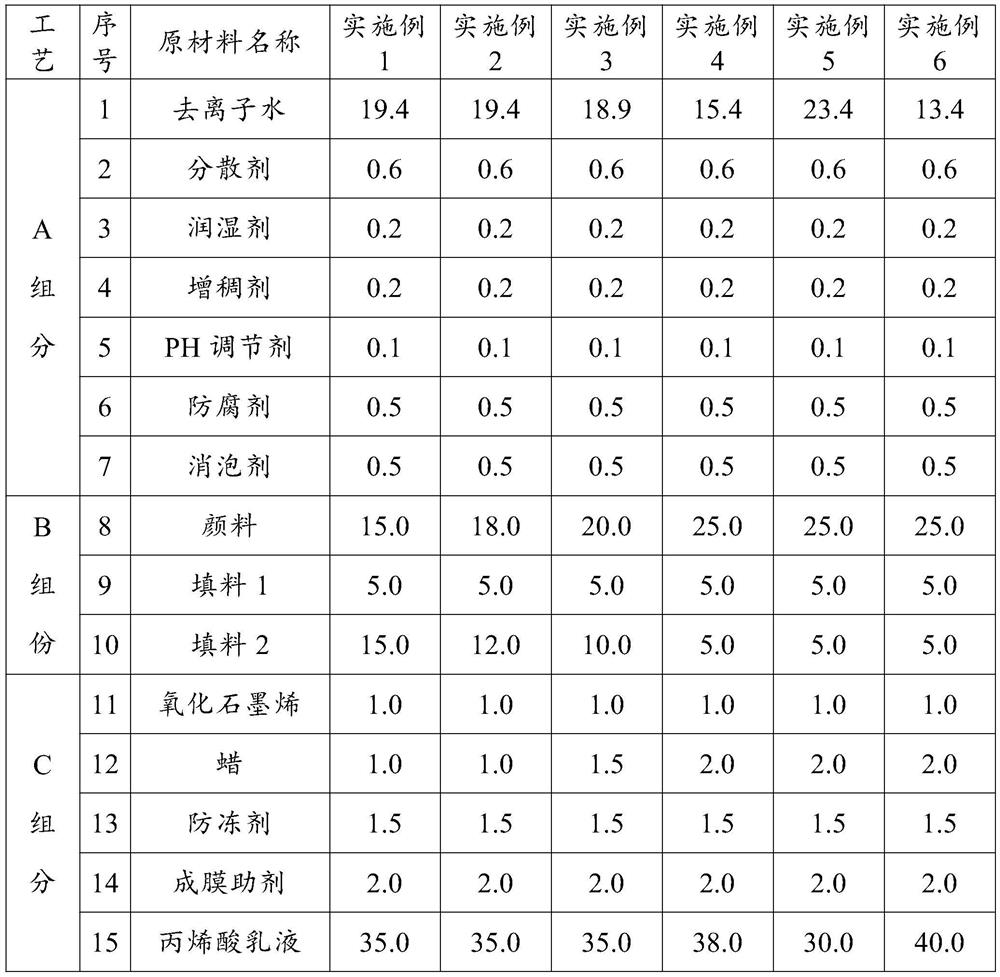

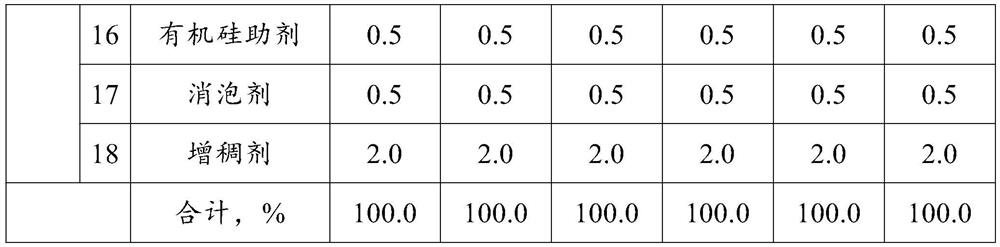

[0031] The anti-scratch and stain-resistant interior wall coatings of Examples 1-6, the raw material ratio is listed in Table 1, and its preparation process includes the following steps:

[0032] S1. Add deionized water into the mixing container, turn on the high-speed disperser, adjust the dispersion speed to 200r / min, and then add component A (dispersant, wetting agent, thickener, pH regulator, preservative , defoamer) into the stirring container, then adjust the dispersion speed to 400r / min, stir and disperse for 5min to make it uniform;

[0033] S2. Adjust the dispersion speed to 1200-1500r / min, then add component B (pigment and filler) into the stirring container in turn, stir and disperse for 30 minutes to make the fineness reach ≤40um;

[0034] S3. Adjust the dispersing speed to 500-800r / min, and sequentially mix component C (graphene oxide, wax, antifreeze, film-forming aid, acrylic emulsion, silicone additive, the remaining defoamer and thickener agent) into the mixi...

Embodiment 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com