High-heat-dissipation multilayer high-frequency copper-based microwave signal plate and preparation process thereof

A microwave signal, high heat dissipation technology, applied in the direction of multilayer circuit manufacturing, non-metallic protective layer coating, structural connection of printed circuits, etc., can solve the problem of anti-soldering blistering, cracking, etc. problem, to achieve the effects of enhanced microwave signal stability, reduced high temperature impact, and large amount of information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

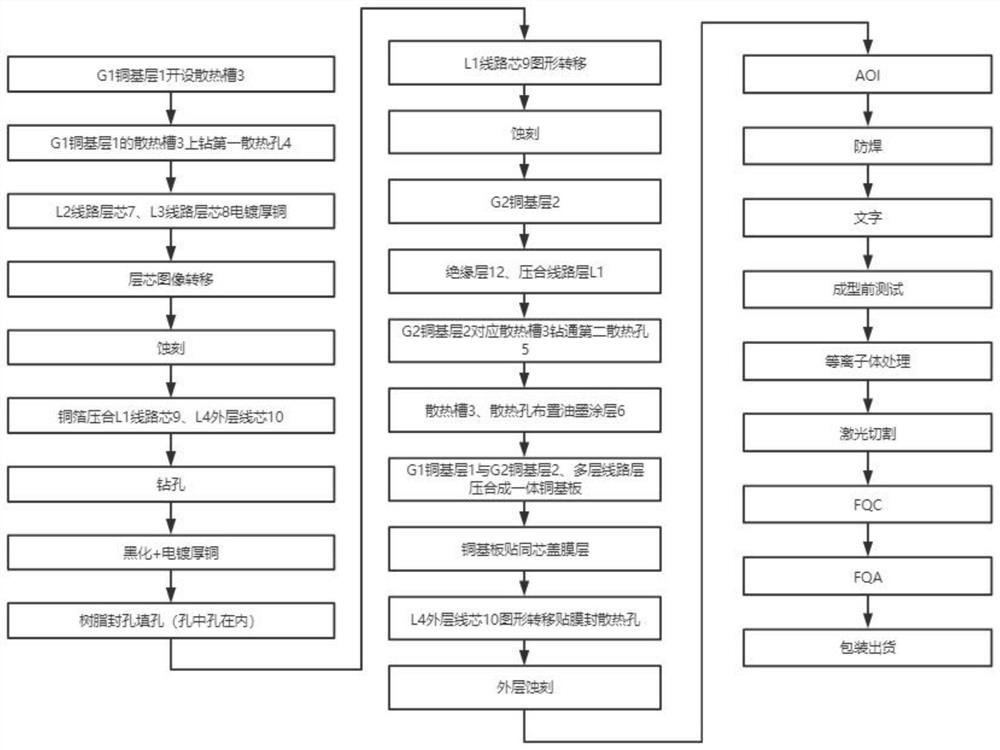

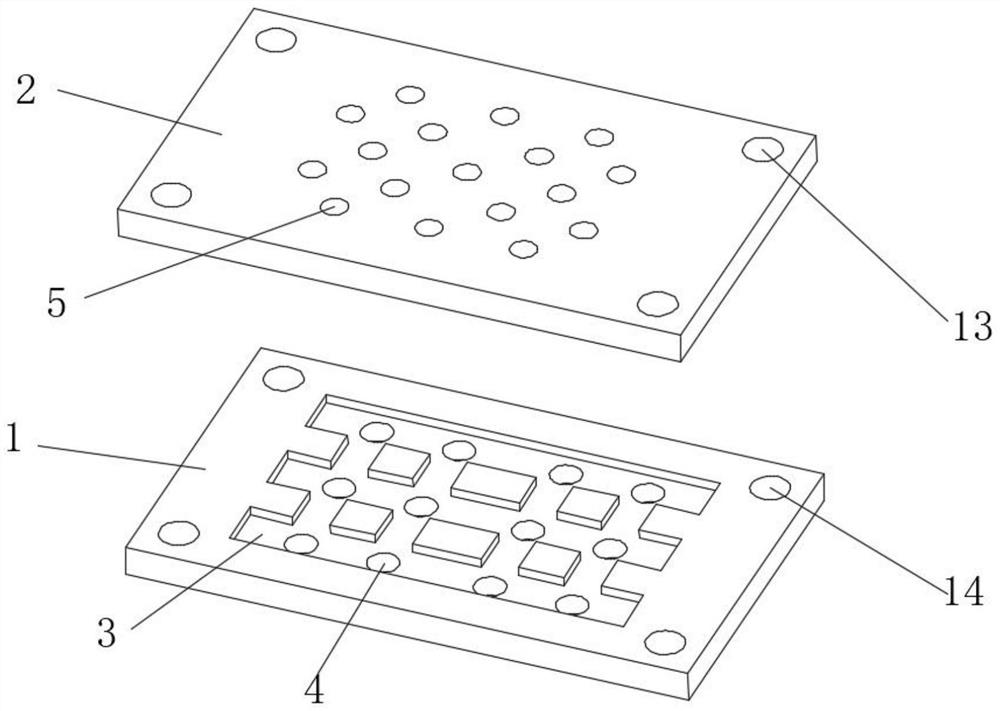

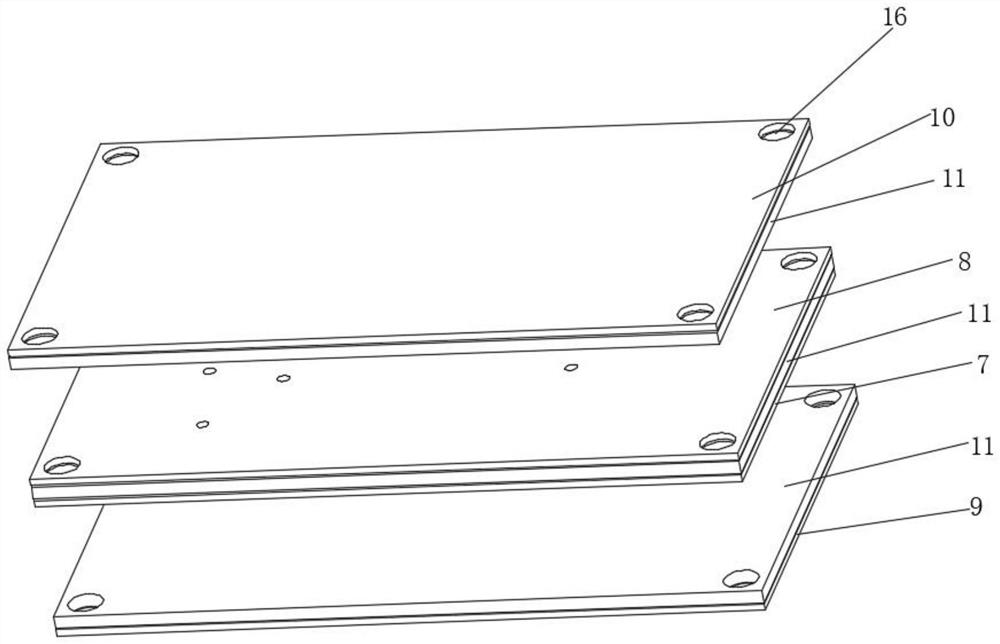

[0054] see Figure 1-9 , a multi-layer high-frequency copper-based microwave signal board with high heat dissipation, including a copper base material 18 and a multi-layer circuit layer, the copper base material 18 includes a G1 copper base layer 1 and a G2 copper base layer 2 bonded through a dielectric layer 11, and more The layer circuit layer is set on the side of the G2 copper base layer 2 away from the G1 copper base layer 1, and the side opposite the G1 copper base layer 1 to the G2 copper base layer 2 is provided with a plurality of horizontally distributed heat sinks 3, and the heat sink 3 is provided with a number of penetrating And the vertically arranged first heat dissipation holes 4, the G2 copper base layer 2 is provided with a number of penetrating and vertically arranged second heat dissipation holes 5, the first heat dissipation holes 4 and the second heat dissipation holes 5 are arranged alternately and the two are projected horizontally They are all located...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com