NiS/graphene and carbon composite material as well as preparation method and application thereof

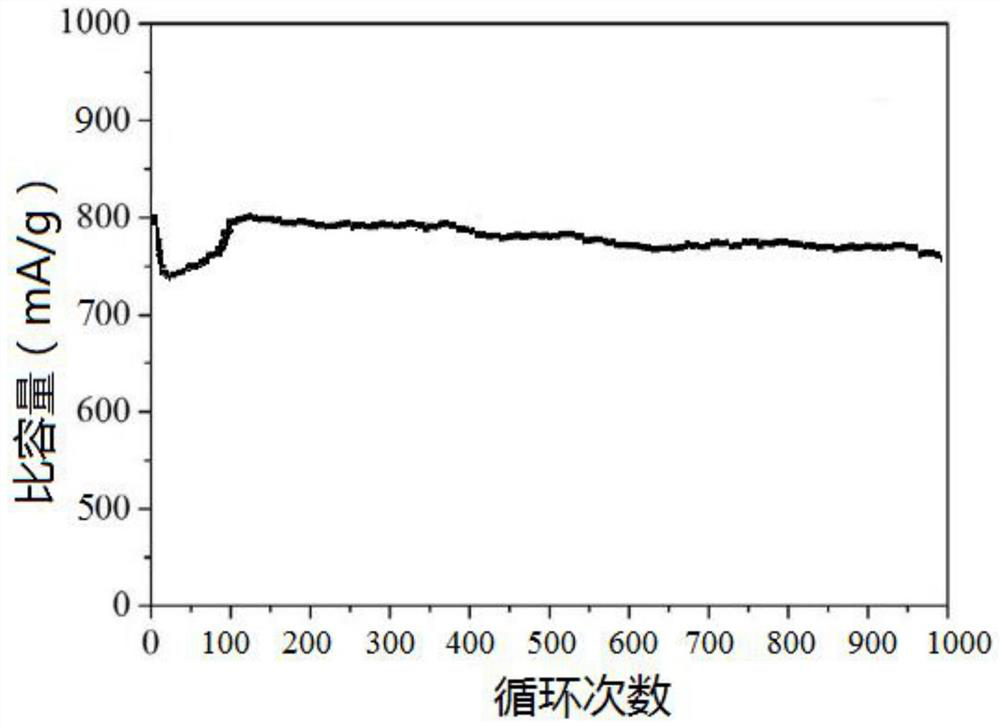

A carbon composite material, graphene technology, applied in electrical components, circuits, battery electrodes, etc., can solve problems such as unfavorable industrialized production, application limitations, poor conductivity, etc., to achieve self-healing ability, improve overall stability, improve The effect of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of NiS / graphene@carbon composite material, comprising the following steps:

[0033] (1) Take nickel nitrate, thiourea and trisodium citrate, then mix nickel nitrate, thiourea and trisodium citrate in methanol in a reaction kettle, and then keep warm at 170°C for 42 hours to perform solvothermal reaction , to obtain nickel sulfide;

[0034] Among them, the ratio of trisodium citrate, thiourea and nickel nitrate is 1:4:1;

[0035] (2) sodium alginate solution and graphene oxide are mixed uniformly, then the nickel sulfide prepared in step (1) is added, after fully mixing, residual bubbles are removed and solvent is evaporated to obtain nickel sulfide / graphene oxide gel;

[0036] Wherein, the mass ratio of sodium alginate and deionized water in the sodium alginate solution is 2:100, the mass ratio of sodium alginate and graphene oxide is 1:0.1, and the mass ratio of sodium alginate and nickel sulfide is 1 : 0.8;

[0037] (3) Add porogen KOH dropwise...

Embodiment 2

[0040] A preparation method of NiS / graphene@carbon composite material, comprising the following steps:

[0041](1) Get nickel chloride hexahydrate, thioacetamide and trisodium citrate, then in the reactor, nickel chloride hexahydrate, thioacetamide and trisodium citrate are mixed in ethylene glycol, then Insulate and react at 200°C for 36 hours, and perform solvothermal reaction to obtain nickel sulfide;

[0042] Wherein, the ratio of trisodium citrate, thioacetamide and nickel chloride hexahydrate is 2:3:1;

[0043] (2) sodium alginate solution and graphene oxide are mixed uniformly, then the nickel sulfide prepared in step (1) is added, after fully mixing, residual bubbles are removed and solvent is evaporated to obtain nickel sulfide / graphene oxide gel;

[0044] Wherein, the mass ratio of sodium alginate and deionized water in the sodium alginate solution is 4:100, the mass ratio of sodium alginate and graphene oxide is 1:0.08, and the mass ratio of sodium alginate and nic...

Embodiment 3

[0048] A preparation method of NiS / graphene@carbon composite material, comprising the following steps:

[0049] (1) Take the hydrate of nickel acetate, L-cysteine and trisodium citrate, and then in the reaction kettle, dissolve the hydrate of nickel acetate, L-cysteine and trisodium citrate in deionized water Mix, then heat-preserve and react at 230°C for 18 hours, and perform solvothermal reaction to obtain nickel sulfide;

[0050] Among them, the ratio of trisodium citrate hydrate, L-cysteine and nickel acetate is 3:2:1;

[0051] (2) Potassium alginate solution and graphene oxide are mixed uniformly, then add the nickel sulfide that step (1) makes, after fully mixing, remove residual bubble and evaporate solvent, obtain nickel sulfide / graphene oxide gel;

[0052] Wherein, the mass ratio of potassium alginate and deionized water in the potassium alginate solution is 6:100, the mass ratio of potassium alginate and graphene oxide is 1:0.05, and the mass ratio of potassiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com