Preparation method of solid-free workover fluid resistant to polyvalent metal cations at ultrahigh temperature

A polyvalent metal, ultra-high temperature technology, applied in the fields of oil exploration, oilfield chemistry and oilfield polymers, can solve the problem of weakening the lithology of washing sand, reducing filtration loss, affecting the anti-aging performance of workover fluid, and loss of viscosity increase, etc. problems, to achieve the effect of inhibiting cross-linking and salt effect, enhancing rigidity, and preventing bacterial growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

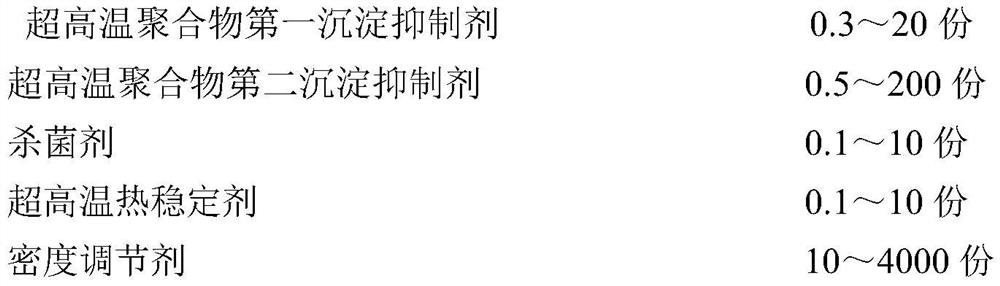

Method used

Image

Examples

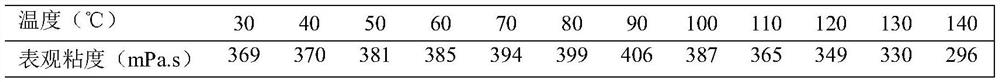

Embodiment 1

[0025] At room temperature, slowly pour 4 grams of Welan gum and 6 grams of Diyou gum into 1000 grams of water under stirring, and then continue to stir until they are completely dissolved. During the stirring process, the prepared thickener solution First add 6 grams of propynyl alcohol and 1 gram of 2-butyne-1,4-diol, then add 5 grams of tetrasodium edetate, 20 grams of sodium formate, 40 grams of potassium formate and 30 grams of potassium propionate, stir for 1 hour, add 0.6 gram of formaldehyde and 0.2 gram of phenol respectively in the stirring process, and continue to stir evenly, then continue to add 0.5 gram of sodium bisulfite and 0.4 gram of thiourea, and mix evenly, finally add 165 gram of sodium chloride, 40 grams of calcium chloride, 3g / L magnesium chloride, 100mg / L ferric chloride and 20mg / L ferrous chloride are used to adjust the density of the workover fluid to obtain a density of 1.185g / cm 3 , Solid-free workover fluid resistant to multivalent metal cations a...

Embodiment 2

[0027] At room temperature, slowly pour 30 grams of welan gum into 1000 grams of water under stirring, and then continue to stir until it is completely dissolved. During the stirring process, add 9 grams of 3 -hexyne-2,5-diol, then add 2 grams of sodium hexametaphosphate, 2 grams of phenanthroline, 80 grams of sodium formate and 30 grams of potassium acetate, stir for 1 hour, and then add 1 gram of pentamyl Dialdehyde and 0.5 gram of sodium trichlorophenate, and continue to stir evenly, then continue to add 1 gram of sodium borohydride and 1 gram of sodium dithionite, and mix well, finally add 100 gram of sodium chloride and 50 gram of calcium chloride, use to adjust the density of the workover fluid to obtain a density of 1.188g / cm 3 , Solid-free workover fluid resistant to multivalent metal cations at ultra-high temperature.

Embodiment 3

[0029] At room temperature, slowly pour 3 grams of gellan gum and 10 grams of welan gum into 1000 grams of water under stirring, and then continue stirring until completely dissolved. During the stirring process, the prepared thickener solution First add 7 grams of 1-n-octyn-3-ol and 2 grams of 2-butyne-1,4-diol, then add 4 grams of triethanolamine, 5 grams of trisodium nitrilotriacetate, 130 grams of potassium formate and 30 1 gram of sodium propionate, stirred for 1 hour, then added 3 gram of succinaldehyde and 2 gram of resorcinol respectively in the stirring process, and continued to stir evenly, then continued to add 4 gram of sodium sulfite and 2 gram of o-xylylthiourea, And mix evenly, finally add 200 grams of sodium chloride and 800 grams of calcium bromide to adjust the density of the workover fluid to obtain a density of 1.725g / cm 3, Solid-free workover fluid resistant to multivalent metal cations at ultra-high temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com