Metal plate drilling equipment for intelligent workshop

A metal sheet and drilling equipment technology, applied in metal processing equipment, welding equipment, laser welding equipment and other directions, can solve the problems of sheet hole forming, impact, inconsistent upper and lower apertures, etc., to improve quality and reduce external factors. , to avoid the effect of resonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the objects and advantages of the present invention clearer, the present invention will be specifically described below in conjunction with examples. It should be understood that the following words are only used to describe one or several specific implementation modes of the present invention, and do not strictly limit the protection scope of the specific claims of the present invention.

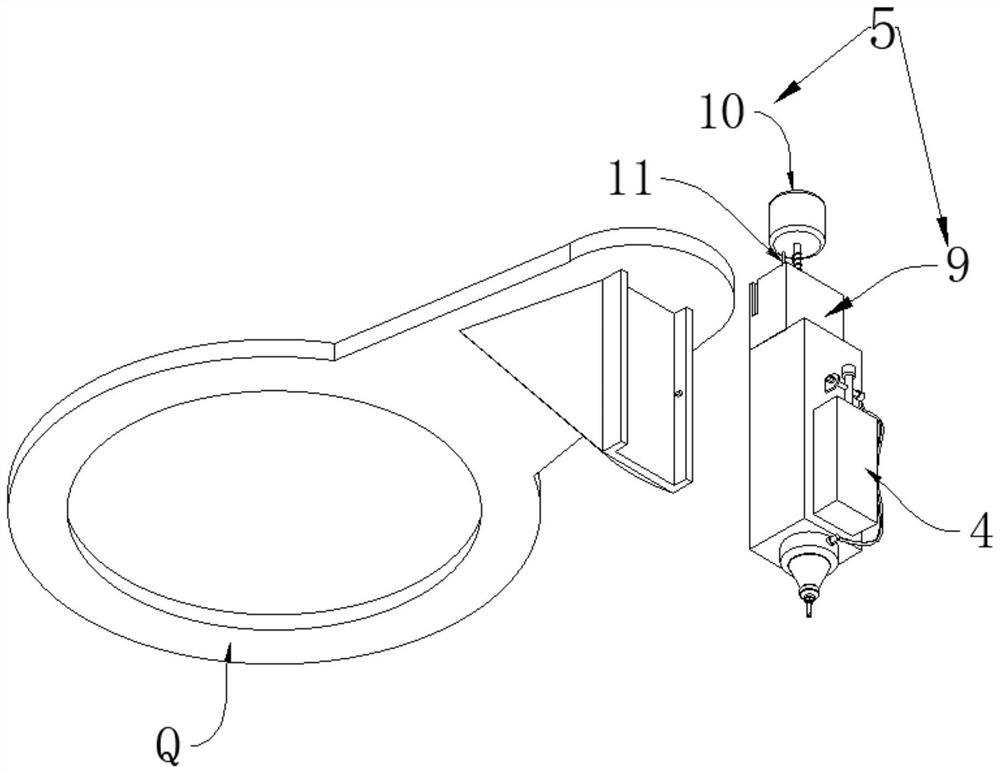

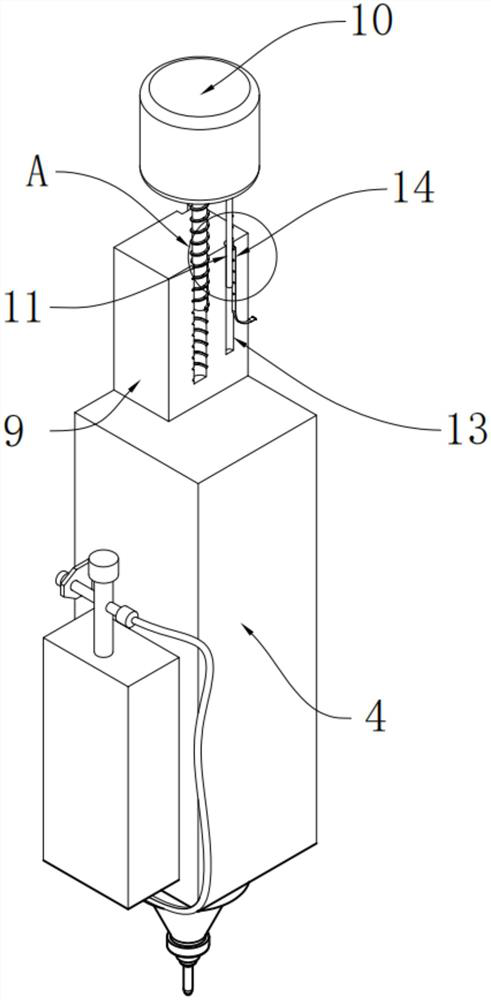

[0036] see Figure 1-11 , a sheet metal drilling equipment for an intelligent workshop, comprising a beam 1, a stroke arm 2 slidably mounted on the bottom of the beam 1, and a working machine tool 3 installed corresponding to the stroke arm 2, the bottom end of the stroke arm 2 can be A laser part 4 for hole extraction is provided in rotation, and a focusing mechanism 5 is provided on the top of the laser part 4 .

[0037] The top of the machine tool 3 is hollow and extends the chamber 6 provided inside. The inner cavity of the machine tool 3 is provided with a sink...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com