A kind of separator comprising graphene/cellulose composite material and preparation method thereof

A composite material and composite material layer technology, applied in the field of separators containing graphene/cellulose composite materials and their preparation, can solve the problem of limiting the service life of lithium-ion batteries, energy density and theoretical capacity, lithium-ion battery energy density and actual capacity. low, threatening personal safety and other problems, to achieve the effect of increasing charge-discharge cycle performance, high liquid absorption, and increasing safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] Preparation of the positive electrode sheet: 85 parts of the positive active material lithium cobaltate, 5 parts of acetylene black, 5 parts of conductive graphite, and 5 parts of PVDF are fully mixed with N-methylpyrrolidone to obtain the positive electrode slurry, which is evenly coated on the surface of the aluminum foil current collector to complete Positive sheet preparation.

[0053] Preparation of negative electrode sheet: 87 parts of conductive graphite, 5 parts of acetylene black, 5 parts of hydroxymethylcellulose sodium binder, and 3 parts of styrene-butadiene rubber binder are fully mixed with ethanol-water mixed solution to obtain negative electrode slurry Material, evenly coated on the surface of the copper foil current collector, to complete the preparation of the negative electrode sheet.

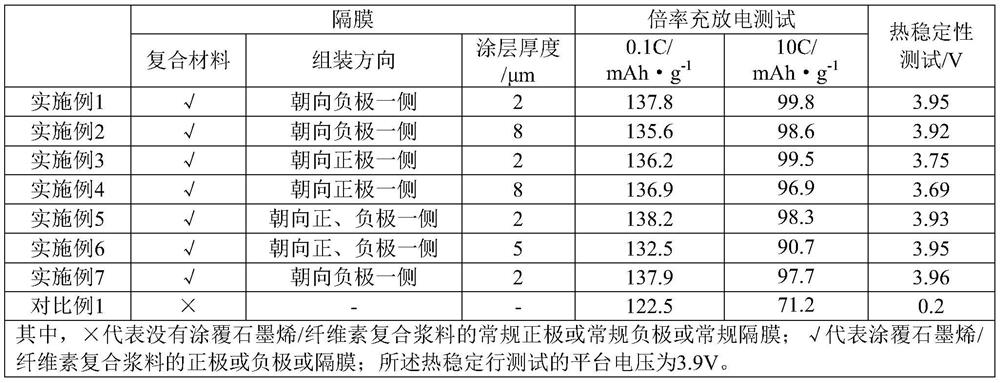

Embodiment 1

[0055] Step 1) fully mix natural flake graphite 60g and methyl cellulose 100g, and ball mill 15h at room temperature to obtain composite graphene cellulose material powder;

[0056] Step 2) Sodium dodecylbenzene sulfonate 25g is dissolved in 460mL water, then the graphene cellulose material 160g obtained in step (1) is dissolved in the above water, fully stirred, and the graphene cellulose mixed slurry is obtained;

[0057] Step 3) applying the mixed slurry scraper of step 2) to one side of the polypropylene diaphragm base layer;

[0058] Step 4) Dry the diaphragm base layer coated with the mixed slurry in step 3) in a vacuum oven at 40° C. for 2 hours to prepare the diaphragm comprising graphene / cellulose composite material; the graphene / cellulose The thickness of the composite coating is 2 μm.

[0059] Step 5) the lithium-ion battery is assembled:

[0060] Put the graphene / cellulose composite diaphragm obtained in step 4) between the positive electrode and the negative ele...

Embodiment 2

[0063] Repeat embodiment 1, difference is:

[0064] Step 1) fully mix natural flake graphite 30g and ethyl cellulose 100g, and ball mill 5h at room temperature to obtain composite graphene cellulose material powder;

[0065] Step 2) dissolving 15g of methyl amyl alcohol in 1500mL water, then dissolving 145g of the graphene cellulose material obtained in step (1) in the above-mentioned water, fully stirring to obtain a graphene / cellulose composite slurry;

[0066] In step 4), the thickness of the graphene / cellulose composite coating is 8 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com