Water-permeable concrete

A permeable concrete and raw material technology, applied in the field of concrete, can solve the problems that the fluidity of permeable concrete cannot meet the requirements of tank truck transportation, etc., and achieve the effects of reducing pore water content, reducing water use, and reducing bleeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

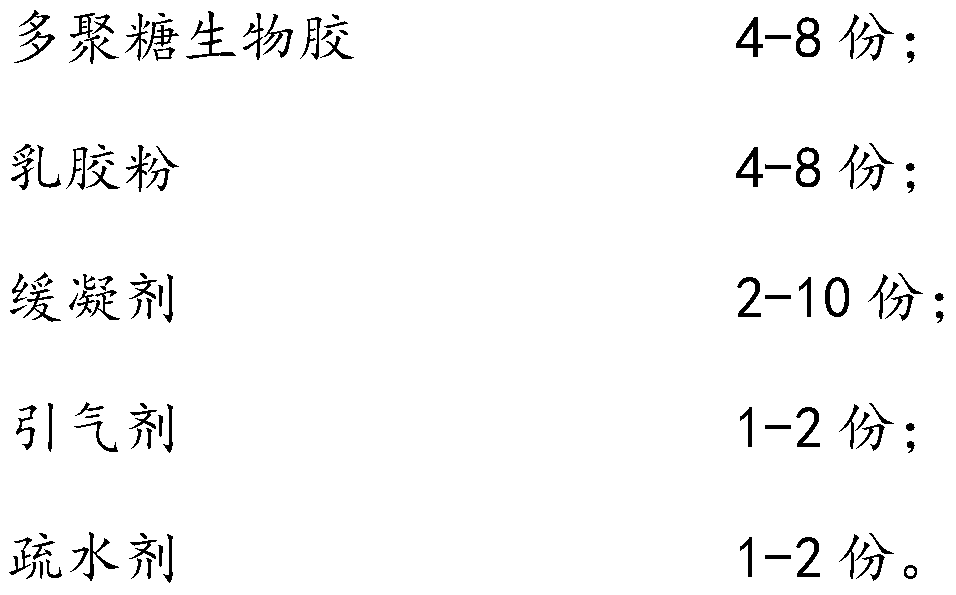

[0065] The invention discloses a permeable concrete, which comprises the following raw materials in parts by weight:

[0066]

[0067] Wherein, reinforcing agent comprises the raw material of following parts by weight:

[0068]

[0069] Wherein, accelerator comprises the raw material of following weight percent:

[0071] Sodium Fluosilicate 14%.

[0072] in,

[0073] The water is local drinking water, the gravel is 5-10mm in particle size; the cement is Jiangnan Onoda brand P.042.5 Portland cement; the silica fume is silica fume from Shanghai Shengkuo Building Materials Co., Ltd. Its specific surface area is greater than or equal to 20000m 2 / kg.

[0074] The polysaccharide biological glue adopts BRGY-300 biological glue of Shijiazhuang Lanyan Building Material Technology Co., Ltd.; the latex powder adopts the latex powder produced by Wacker Company of Germany; the retarder adopts sodium gluconate; the air-entraining agent adopts Qingda...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com