Method for preparing vanadium electrolyte for all-vanadium redox flow battery

A technology for all-vanadium redox flow batteries and electrolytes, which is applied in the field of preparing vanadium electrolytes for all-vanadium redox flow batteries, which can solve the problems of increasing the transportation cost of vanadium electrolytes and relatively large restrictions on vanadium electrolytes, so as to reduce incomplete conversion , low cost, small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

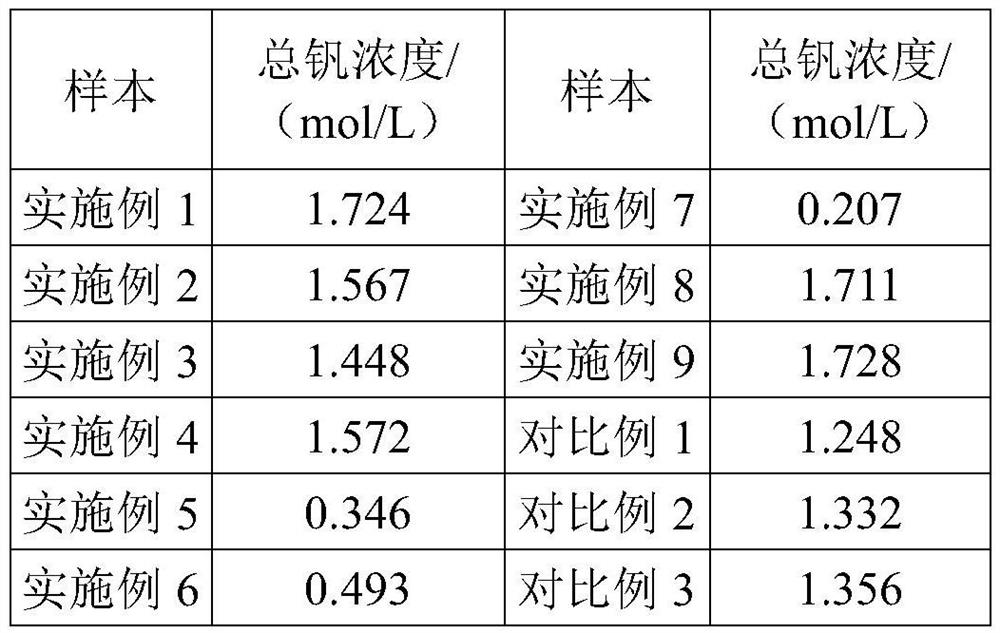

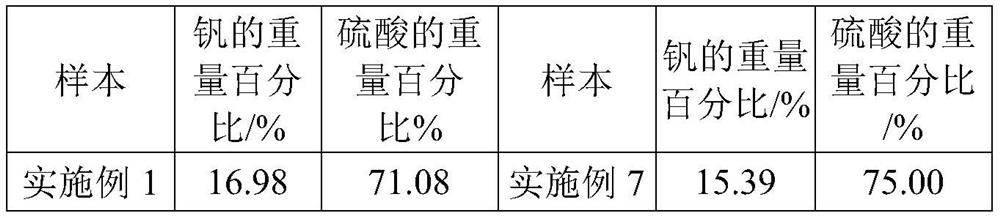

Examples

Embodiment 1-5

[0036] Example 1 is taken as an example for description below.

Embodiment 1

[0038] In embodiment 1, vanadium electrolyte is prepared according to the following steps:

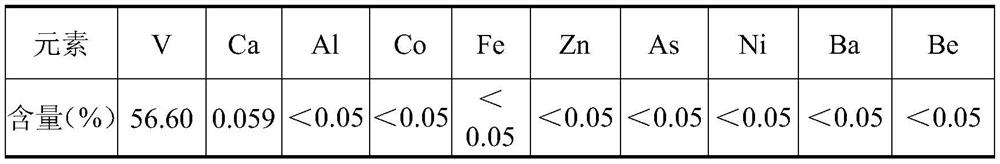

[0039] (1) Take 10g of high-purity vanadium pentoxide, put it into a crucible, put the crucible into a heating device, heat it at 600°C for 4h, and pass hydrogen into the crucible at a rate of 250mL / min while heating , obtain calcine after heating, and calcine is low-valent vanadium oxide; The composition of metal element in high-purity vanadium pentoxide is as shown in table 1;

[0040] (2) Take 4g of low-valent vanadium oxide, put it into a glass dish, add a total of 12g of concentrated sulfuric acid to the glass dish, put the glass dish into a heating device, heat it at 300 ° C for 2h, and generate a yellow-green solid after the reaction is completed material, the yellow-green solid material is the vanadium-containing paste electrolyte; in this step, the mass fraction of concentrated sulfuric acid is 98%;

[0041] (3) The vanadium-containing paste electrolyte is mixed with water at...

Embodiment 2

[0045] The difference between this example and Example 1 is that the heating temperature in step (1) is 650° C., the heating time is 2 h, and the rate of hydrogen gas feeding is 200 mL / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com