Control system and method for heat throwing load of steam extraction heat supply unit

A steam extraction heating unit and control system technology, applied in the control system, steam generation method using pressure combustion, control combustion, etc., can solve energy imbalance, heat compressor steam turbine load mismatch, and sudden drop in reheat steam temperature and other issues to achieve the effect of ensuring stable heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

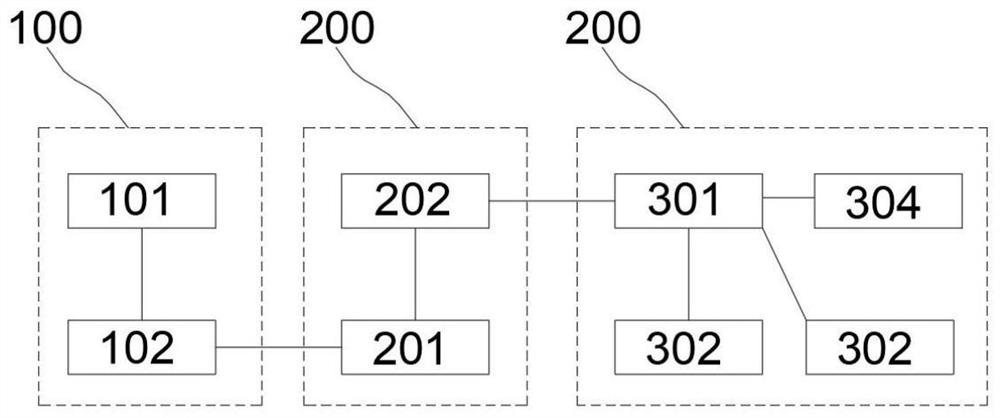

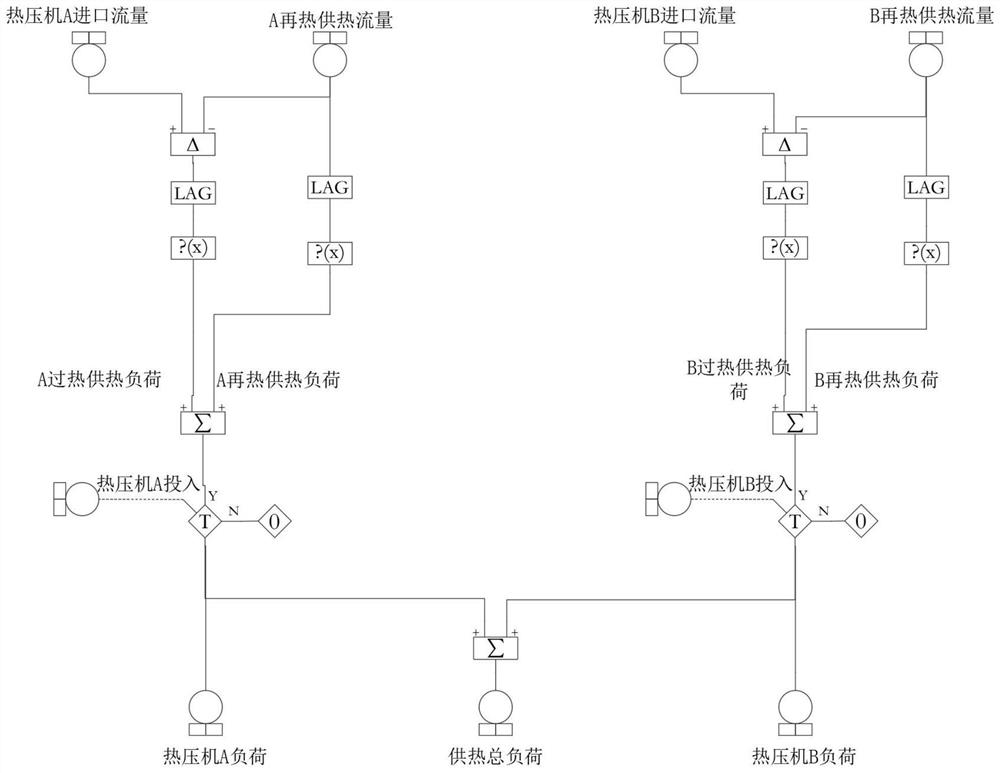

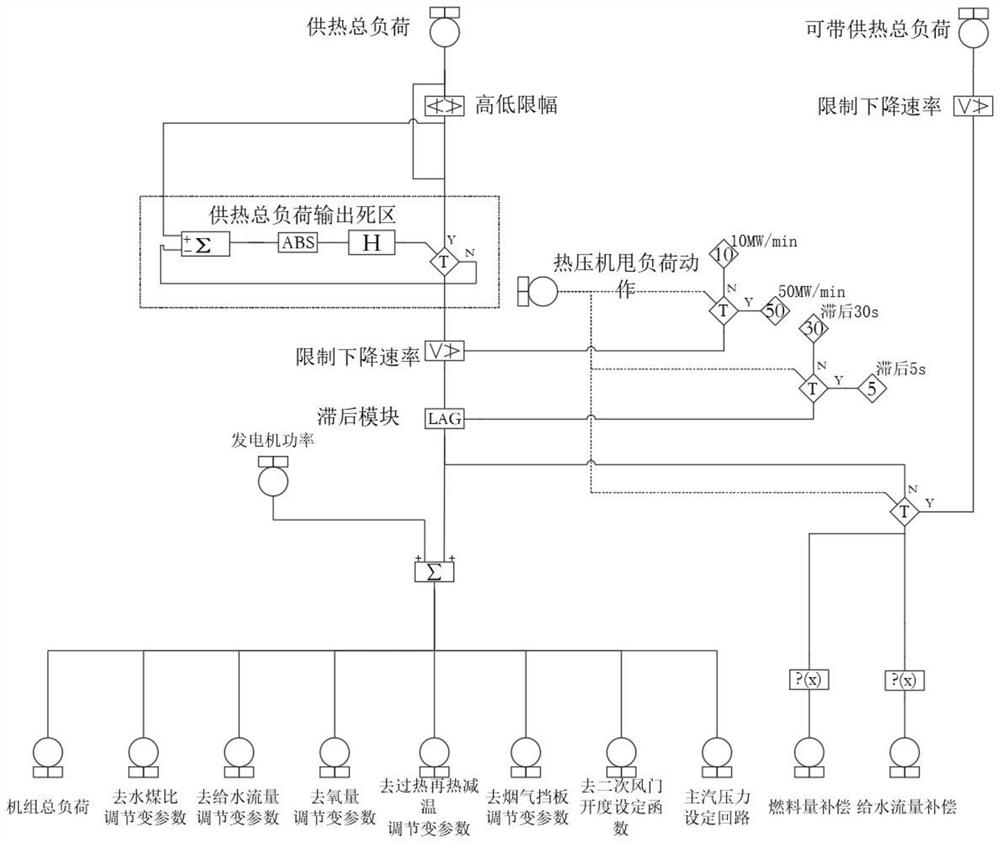

[0028] refer to figure 1 , 2 , which is the first embodiment of the present invention, this embodiment provides a control system and method for heat rejection of steam extraction and heating units, including an acquisition module 100, a control module 200 and an execution module 300, and the acquisition module 100 is used to acquire Enter the actual input flow value of the pulverized coal amount of the hot press, set the actual flow value as the first flow value, and set the rated pulverized coal input flow value of the hot press as the second flow value, and set the first flow value and The second flow value is converted into the first heat load value and the second heat load value. The actual input flow value of pulverized coal, the average calorific value of pulverized coal and the conversion power of the hot press can be calculated to obtain the actual output of the hot press. Provide heat.

[0029] The thermal load threshold is preset in the control module 200, and the ...

Embodiment 2

[0035] refer to Figure 3-6 , which is the second embodiment of the present invention, which is based on the previous embodiment, a control system for rejecting heat load of a steam extraction heating unit, which includes:

[0036] S1: collect the actual input flow value that enters the pulverized coal amount of the hot press by the acquisition module 100, and the actual flow value is set to the first flow value;

[0037] S2: The processing chip 102 calculates and obtains a first heat load value according to the first flow value;

[0038] S3: the processing chip 102 calls the internal second flow value, calculates the second flow value to obtain the second heat load value;

[0039] S4: Calculate the heat load difference between the first heat load value and the second heat load value through the subtractor 201.

[0040] S5: The rated pulverized coal input flow value of the hot press is set as a second flow value, and the first flow value and the second flow value are convert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com