Preparation method of asymmetric hollow porous composite material

A porous composite material, asymmetric technology, applied in the preparation/purification of carbon, chemical instruments and methods, carbon compounds, etc., can solve the problems of complicated steps, large environmental pollution, high cost, and achieve the effect of simple and easy method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]Pipette 200.0mL of deionized water into a 500mL round bottom flask, then add 14g of polystyrene balls, 0.6g of 3-methacryloyloxypropyltrimethoxysilane, 0.6g of sodium lauryl sulfate, 0.6 g of potassium persulfate and 0.3mL of ammonia water were mixed uniformly and reacted at 80°C for 8h. After taking it out, it is centrifuged, rinsed with water and ethanol respectively, and dried to obtain asymmetric structure organosilicon-polystyrene nanoparticles. Subsequently, 1 g of asymmetric structure silicone-polystyrene nanoparticles was added into 200 mL of 0.1 mol / L Tris hydrochloride solution, and reacted at 35° C. for 8 h. After taking it out, it is centrifuged, rinsed with water and ethanol respectively, and dried to obtain an asymmetric composite material coated with polydopamine. 1.0 g of polydopamine-coated asymmetric composite material was calcined at 650° C. for 2 h under nitrogen atmosphere to obtain an asymmetric hollow porous composite material.

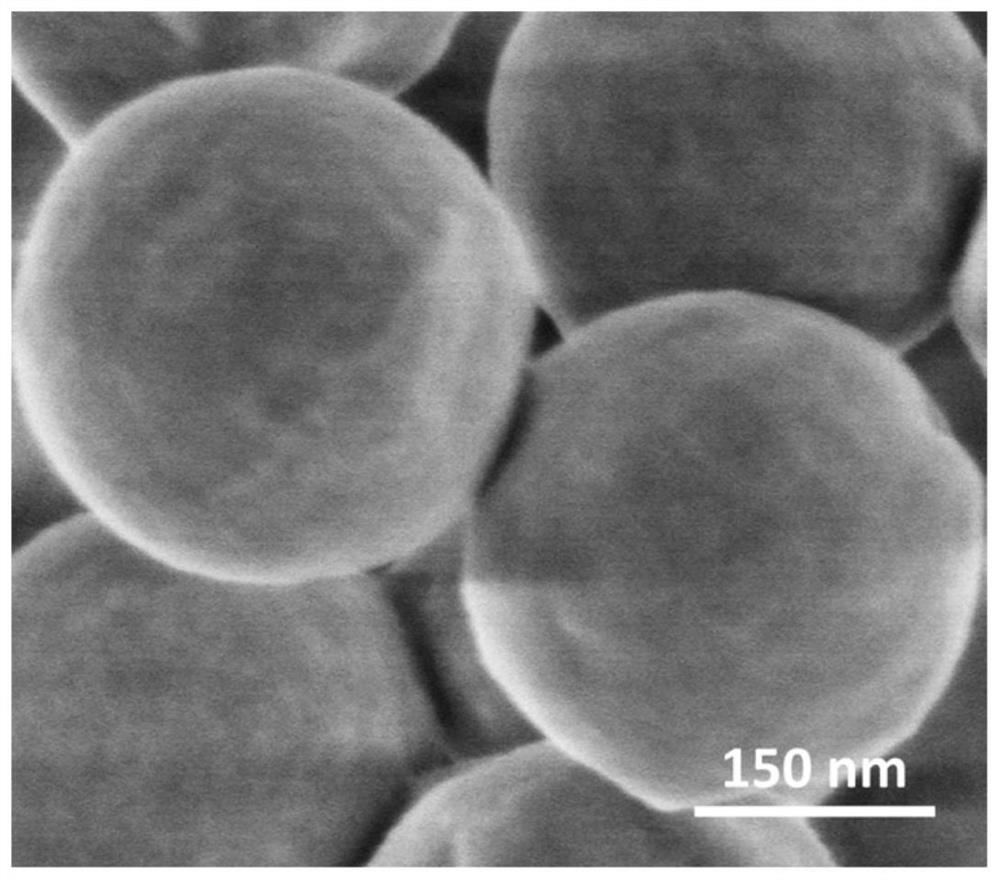

[0045] The scann...

Embodiment 2

[0047] Pipette 200.0mL of deionized water into a 500mL round bottom flask, then add 14g of polystyrene balls, 0.1g of 3-methacryloyloxypropyltrimethoxysilane, 0.6g of sodium lauryl sulfate, 0.6 g of potassium persulfate and 0.3mL of ammonia water were mixed uniformly and reacted at 80°C for 8h. After taking it out, it is centrifuged, rinsed with water and ethanol respectively, and dried to obtain asymmetric structure organosilicon-polystyrene nanoparticles. Subsequently, 1 g of asymmetric structure silicone-polystyrene nanoparticles was added into 200 mL of 0.1 mol / L Tris hydrochloride solution, and reacted at 35° C. for 8 h. After taking it out, it is centrifuged, rinsed with water and ethanol respectively, and dried to obtain an asymmetric composite material coated with polydopamine. 1.0 g of polydopamine-coated asymmetric composite material was calcined at 650° C. for 2 h under nitrogen atmosphere to obtain an asymmetric hollow porous composite material.

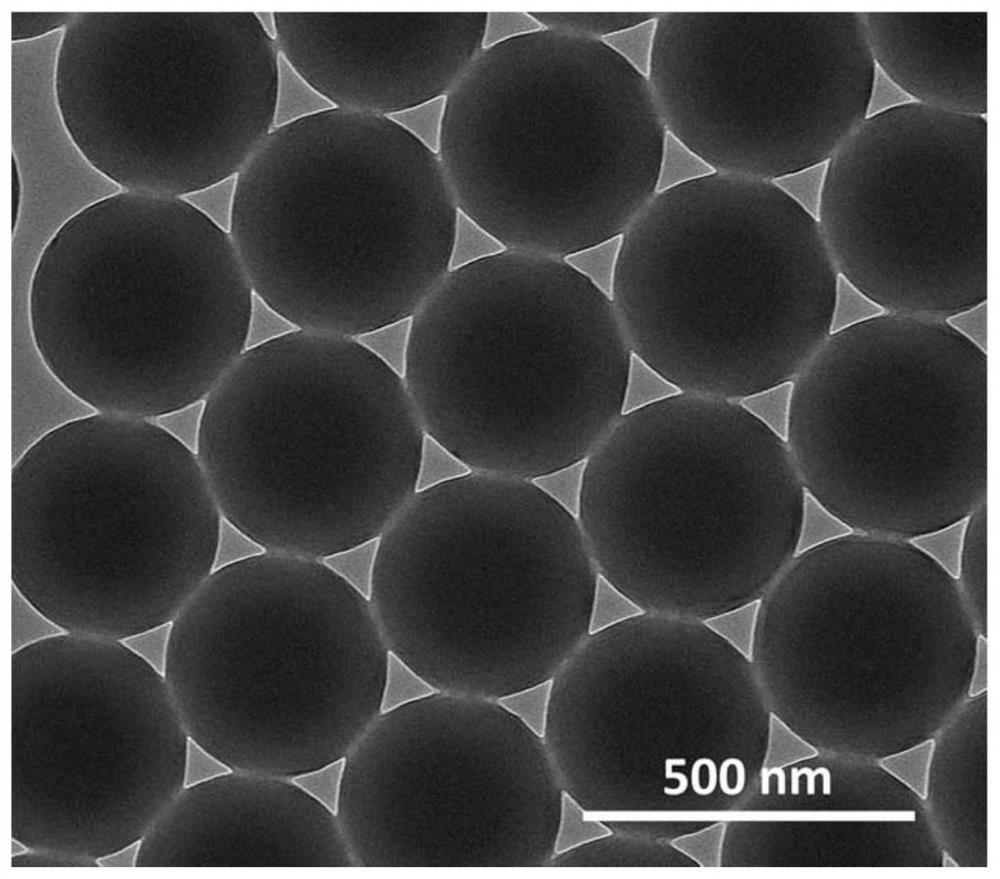

[0048] The SEM ...

Embodiment 3

[0050] Pipette 200.0mL of deionized water into a 500mL round bottom flask, then add 14g of polystyrene balls, 1.2g of 3-methacryloyloxypropyltrimethoxysilane, 0.6g of sodium lauryl sulfate, 0.6 g of potassium persulfate and 0.3mL of ammonia water were mixed uniformly and reacted at 80°C for 8h. After taking it out, it is centrifuged, rinsed with water and ethanol respectively, and dried to obtain asymmetric structure organosilicon-polystyrene nanoparticles. Subsequently, 1 g of asymmetric structure silicone-polystyrene nanoparticles was added into 200 mL of 0.1 mol / L Tris hydrochloride solution, and reacted at 35° C. for 8 h. After taking it out, it is centrifuged, rinsed with water and ethanol respectively, and dried to obtain an asymmetric composite material coated with polydopamine. 1.0 g of polydopamine-coated asymmetric composite material was calcined at 650° C. for 2 h under nitrogen atmosphere to obtain an asymmetric hollow porous composite material.

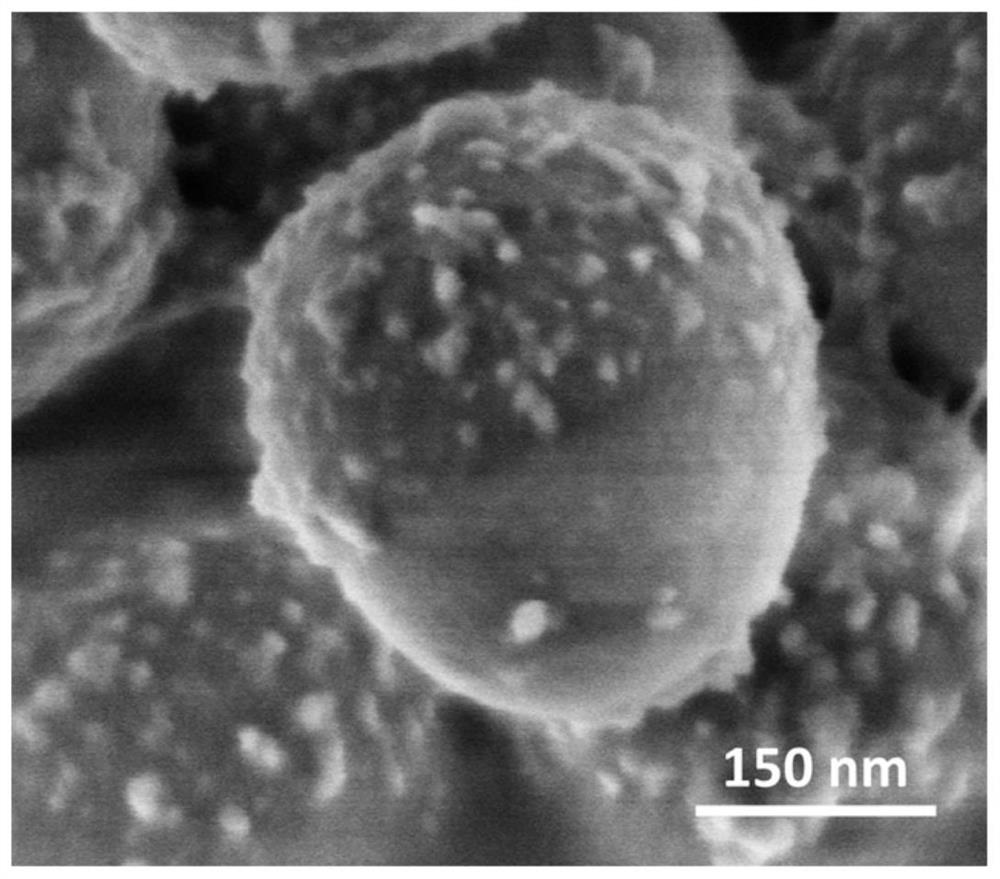

[0051] The SEM ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com