Catalyst loading device for degrading macromolecular organic compound through electron beam irradiation

A technology of electron beam irradiation and organic compounds, applied in the direction of physical/chemical process catalysts, chemical/physical processes, water pollutants, etc., can solve the problems of high equipment investment costs, reduce investment and operation costs, reduce treatment costs, The effect of enhancing biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

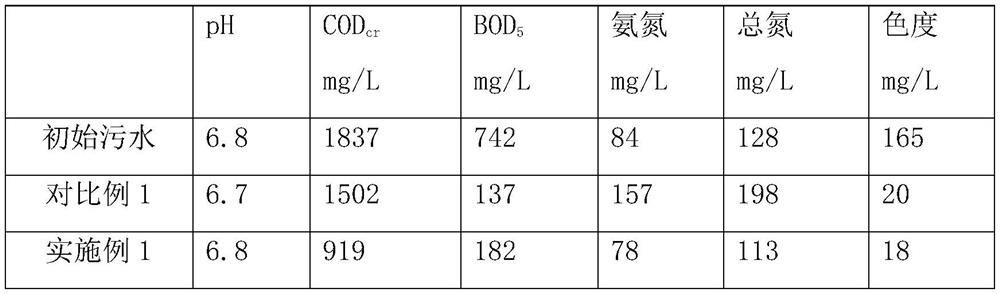

Embodiment 1

[0050] Catalyst-supported stainless steel mesh was prepared by the following process:

[0051] Weigh 8 mol of aluminum chloride and add it into 5 L of methanol and stir evenly to obtain solution A. Mix 1L of deionized water and 1L of methanol, add hydrochloric acid to adjust the pH to 3, add 0.8mol of copper sulfate, 1mol of nickel sulfate, and 1.5mol of urea solid powder for dissolution to obtain solution B. Solution A and solution B were mixed and sonicated for 1 hour to form a gel. Dry at 80°C for 24 hours to obtain a xerogel. After being processed into powder with a grinder, it was placed in a muffle furnace and calcined at 450°C for 5 hours to obtain a dry powder. Mix 50g of acrylic powder with dry powder and stir evenly, then put it into an electrostatic powder spraying chamber, and spray the charged powder onto the surface of a 30-mesh stainless steel mesh under a pressure of 1.1 atmospheres to form a coating. Treat at 180°C for 30 minutes to obtain a stainless steel...

Embodiment 2

[0062] Catalyst-supported stainless steel mesh was prepared by the following process:

[0063] Weigh 10 mol of aluminate and add into 5L of absolute ethanol and stir evenly to obtain solution A. Add 1 mol of manganese acetate, 1 mol of copper chloride, 1 mol of nickel sulfate, and 2 mol of ammonium carbonate solid powder into a mixed solution of 2 L of deionized water and 2 L of absolute ethanol (add hydrochloric acid to adjust the pH to 3) and dissolve to obtain solution B. Solution A and solution B were mixed and sonicated for 1.5 hours to form a gel. Dry at 80°C for 24 hours to obtain a xerogel. After being processed into powder with a grinder, it was placed in a muffle furnace and calcined at 480 °C for 5 hours to obtain a dry powder. Mix 60g of epoxy resin powder with dry powder and stir evenly, then put it into an electrostatic powder spraying chamber, and spray the charged powder onto the surface of a 30-mesh stainless steel mesh under a pressure of 1.1 atmospheres to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com