Polyphenol-silk fibroin-polyethylene glycol medical tissue adhesive as well as preparation method and application thereof

A technology of silk fibroin and polyethylene glycol, which is used in the preparation of biomedical materials and biomedical applications, can solve the problems of low adhesion strength on wet surfaces, obstacles to wide application, poor antibacterial performance, etc., and achieve excellent biocompatibility, Excellent antibacterial properties, the effect of increasing cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A. Weigh 2g of shredded silkworm cocoons, put them into a sodium carbonate solution with a mass fraction of 2%, bath ratio 1:50, temperature 100°C, time 30min, degumming 3 times. Wash the degummed silk fibroin repeatedly with deionized water, and dry it in an oven at 60°C. Weigh an appropriate amount of silk fibroin and dissolve it in LiBr solution, place it in a 60°C water bath for 6 hours, and shake it slightly every hour to make it dissolve evenly. Pour the dissolved silk fibroin solution into a dialysis bag (molecular weight cut-off 7000), dialyze with deionized water for 3 days, replace the deionized water every 8h, and obtain a silk fibroin solution with a concentration of 40mg / ml.

[0029] B. Add carboxyl activator (0.16g NHS, 0.12g EDC) to 5ml silk fibroin solution, keep stirring for 30min under water bath conditions of 40°C, then add 2ml polyethylene glycol (20000Da ) solution continued to stir for 30min to obtain a mixed solution.

[0030] C. Weigh 10g of ta...

Embodiment 2

[0032] A. Weigh 2 g of shredded cocoons, put them into sodium bicarbonate with a mass fraction of 4%, bath ratio 1:50, temperature 100°C, time 30 min, degumming 3 times. Wash the degummed silk fibroin repeatedly with deionized water, and dry it in an oven at 60°C. Place an appropriate amount of dried silk fibroin in a ternary system solution with a molar ratio of CaCl2 / C2H5OH / H2O of 1:2:8, place it in a water bath at 60°C for 3 hours, and shake it slightly every hour to dissolve it uniform. Pour the dissolved silk fibroin solution into a dialysis bag (molecular weight cut-off 70000), dialyze with deionized water for 3 days, and change the deionized water every 8 hours to obtain a silk fibroin solution with a concentration of 40mg / ml.

[0033] B. Add carboxyl activator (0.16g NHS, 0.12g EDC) in 5ml silk fibroin solution, under keeping 40 ℃ of water bath conditions, stir 30min, then add 1.2ml concentration and be the polyethylene glycol of 0.1g / ml ( 20000Da) solution was stirr...

Embodiment 3

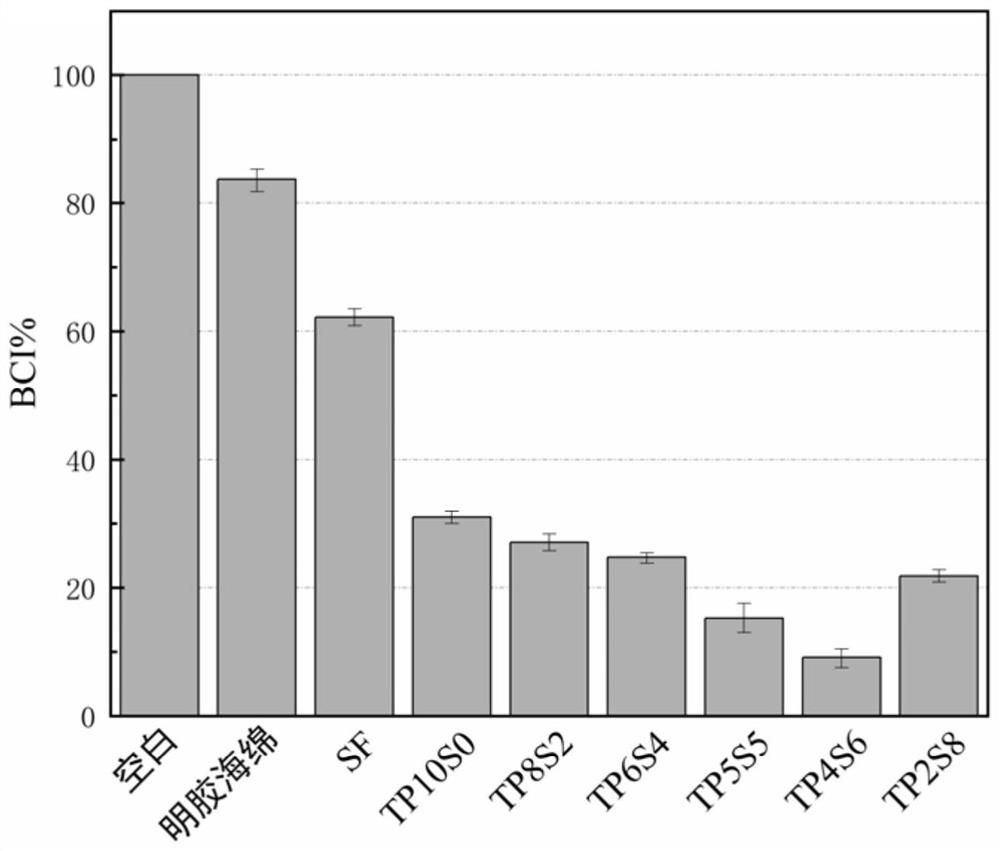

[0036] (1) Under the joint action of polyethylene glycol and polyphenolic compounds, silk fibroin rapidly precipitates from the solution, and forms the first layer of network structure with polyphenolic compounds under the action of hydrophobic-hydrogen bonds, while polyethylene glycol and polyphenolic compounds Polyphenolic compounds form the second layer of network structure through strong hydrogen bonds. At the same time, silk fibroin undergoes self-crosslinking under the action of carboxyl activators, which increases the cohesive force of the adhesive, thereby obtaining a multi-layer adhesive with adhesive properties. Phenol-Silk Fibroin-Polyethylene Glycol Medical Tissue Adhesive.

[0037] (2) The specific preparation steps of a polyphenol-silk fibroin-polyethylene glycol medical tissue adhesive are as follows:

[0038] A. Preparation of silk fibroin solution: under 100°C water bath heating condition, degumming process is carried out to silk with weak lye; after drying, dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com