Lightweight SMD antenna module

An antenna module and lightweight technology, which is applied in the field of lightweight SMD antenna modules, can solve problems such as inconvenient automatic production, high cost of ceramic antennas, and complicated installation process, so as to facilitate automatic production, enhance processing effects, and improve product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

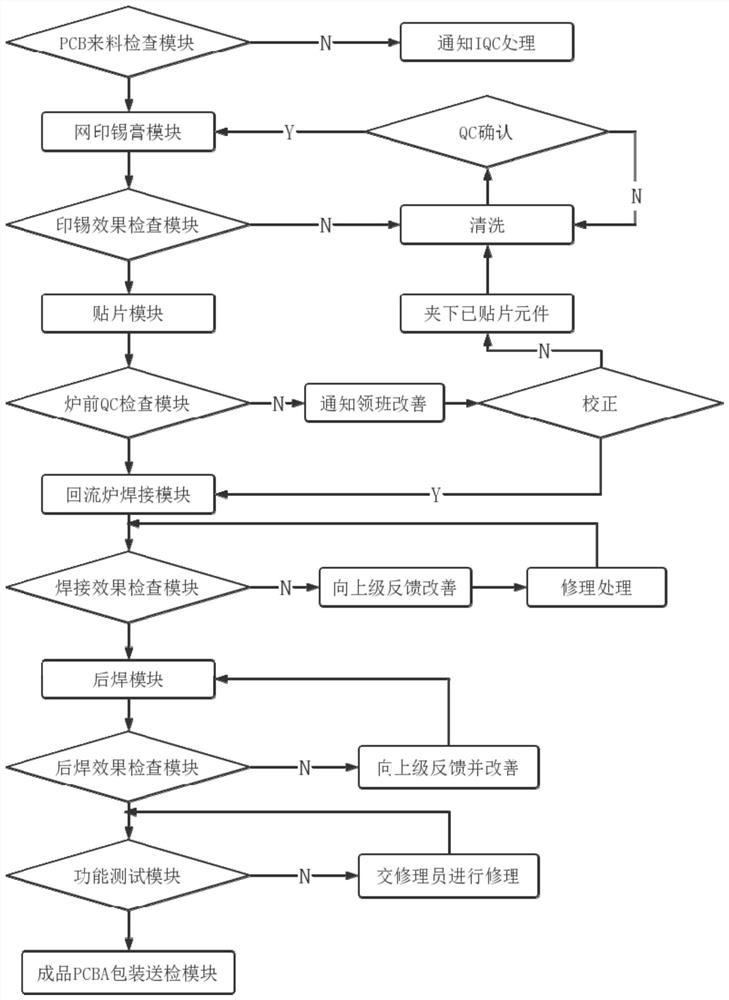

[0040] see figure 1 , a lightweight SMD antenna module, including a PCB incoming inspection module 1, the outer end of the PCB incoming inspection module 1 is provided with a screen printing solder paste module 2, and the outer end of the screen printing solder paste module 2 is provided with a tin printing effect inspection Module 3, the outer end of the tin printing effect inspection module 3 is equipped with a patch module 4, the outer end of the patch module 4 is equipped with a pre-furnace QC inspection module 5, and the outer end of the pre-furnace QC inspection module 5 is equipped with reflow furnace welding Module 6, the outer end of the reflow furnace welding module 6 is provided with a welding effect inspection module 7, the outer end of the welding effect inspection module 7 is provided with a post-welding module 8, and the outer end of the post-welding module 8 is provided with a post-welding effect inspection module 9 , the outer end of the post-soldering effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com