Industrial vehicle dynamic performance improvement method

A dynamic performance, industrial vehicle technology, applied in the direction of motor generator control, electromechanical brake control, electromechanical transmission device control, etc., can solve the problems of slow response, different response speeds of forklifts, and the feedforward effect is not optimal, etc., to achieve Reduce the burden, improve the current response curve, and optimize the effect of driving experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

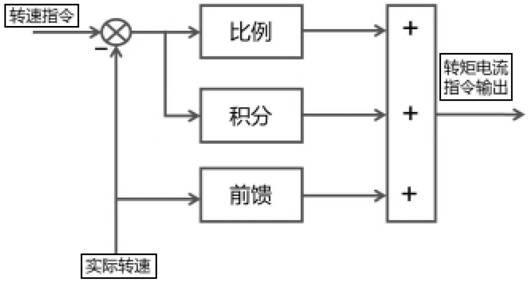

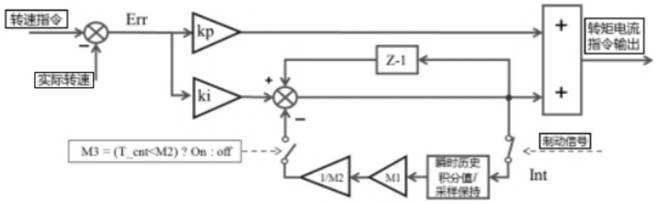

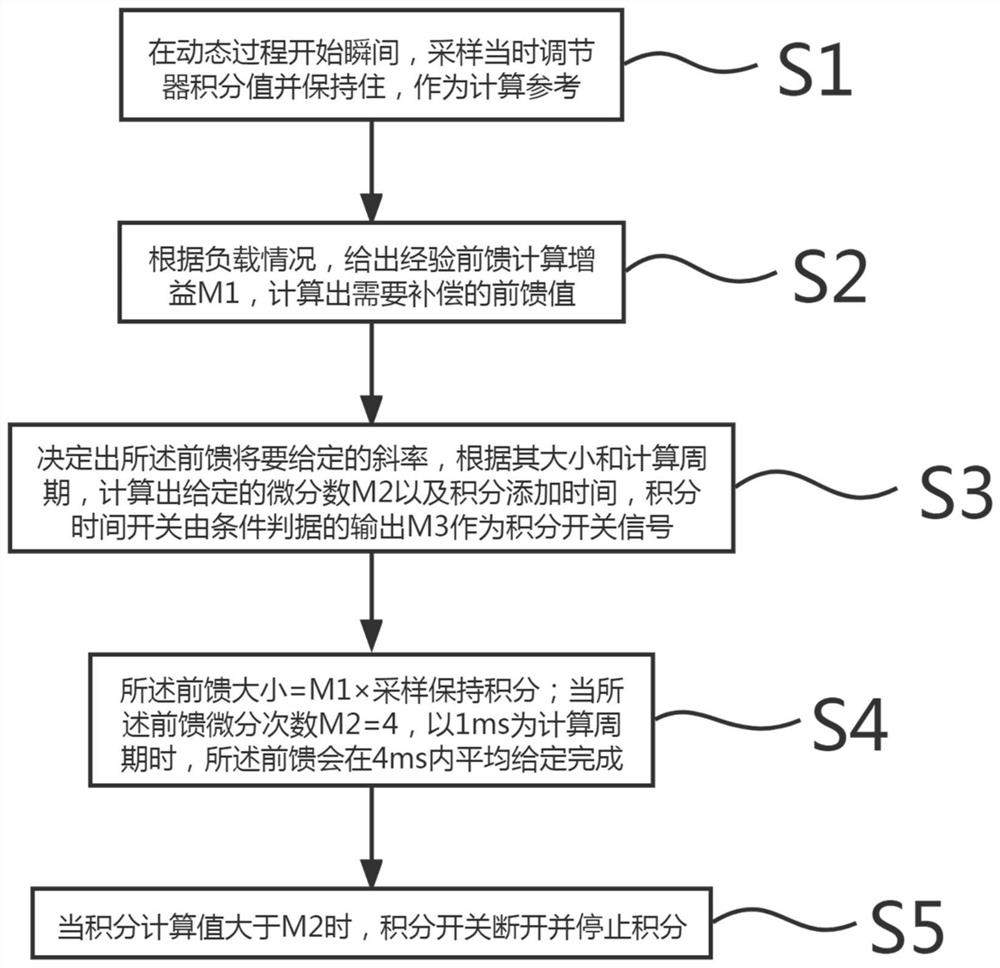

[0032] Such as figure 1 As shown in Fig. 1, a method for improving the dynamic performance of industrial vehicles, the traditional current command feed-forward given method is connected in parallel to the output terminal of the PI regulator in a biased manner.

[0033] Current command feedforward is a commonly used compensation method in the control loop. According to the load characteristics, it can be roughly divided into two types: acceleration feedforward and friction force feedforward. At present, a large number of literatures focus on the calculation of feedforward value. How to effectively give this problem is relatively rare, so if the above problems are solved, the effect of feedforward can be maximized.

[0034] In the speed-current double-closed-loop motor control system, in order to improve the speed response speed, it is often implemented by adding current command feedforward. The addition method is directly added to the output terminal of the PI regulator in the ...

no. 2 example

[0054] Combined with the actual use scenarios of industrial vehicles such as forklifts, since forklifts need to work forward with loads during driving, in the case of different road surfaces and loads, the forklifts need to set the feed-forward value during the actual braking process. The method is different. The control system in the forklift can further judge the saturation degree of the integral item by judging the load on the road surface, and then control the direction of adding the feedforward value, so as to obtain the optimal response result and improve the forklift driving. actual driving comfort.

[0055] An industrial forklift, which is suitable for the method for improving the dynamic performance of an industrial vehicle provided in the first embodiment, includes a forklift, the front end of the forklift is provided with a fork, and the top of the fork is provided with a weight sensor for detecting The weight of the fork.

[0056] Specifically, the position of the...

no. 3 example

[0061] It can be seen from the second embodiment that when the load of the forklift reaches the set threshold, the feedforward value needs to be directly added to the integral item, so as to ensure that the accumulation of the negative feedforward value in the integral item can offset / reduce the original There is an integral value, which is equivalent to the effect of fast withdrawal of the integral, and it also increases the response speed of the current command. However, if the forklift’s load reaches the set threshold, but the driving condition of the forklift is poor, the road condition will affect the forklift. Apply a certain amount of braking force to ensure that the forklift can quickly withdraw points. If the method of adding the feedforward value is still judged only by the load value of the forklift, it will affect the actual driving situation, and further affect the braking force and driving experience of the vehicle. make an impact.

[0062] Both the front end and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com