Magnesium-doped lithium iron phosphate/carbon composite microsphere with high tap density as well as preparation method and application of magnesium-doped lithium iron phosphate/carbon composite microsphere

A technology of tap density and lithium iron phosphate, applied in the direction of electrical components, circuits, battery electrodes, etc., can solve the problems of low electronic conductivity, low tap density, and low ion diffusion rate, and achieve electronic conductivity and ion diffusion High efficiency, high tap density, improved electronic conductivity and ion diffusivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

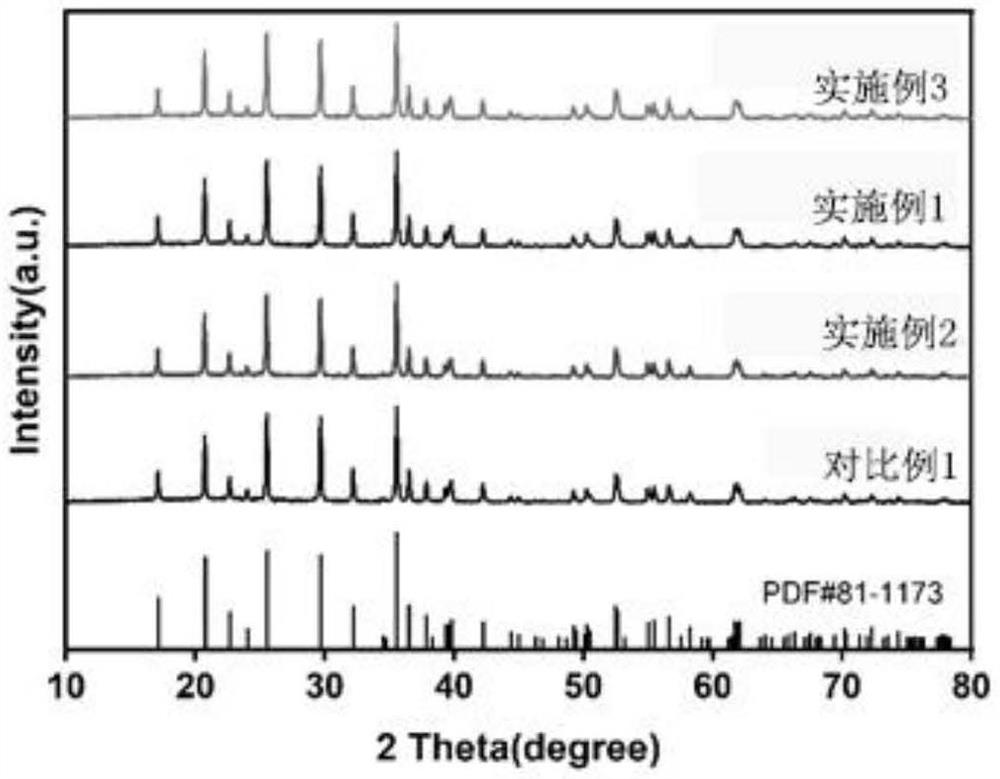

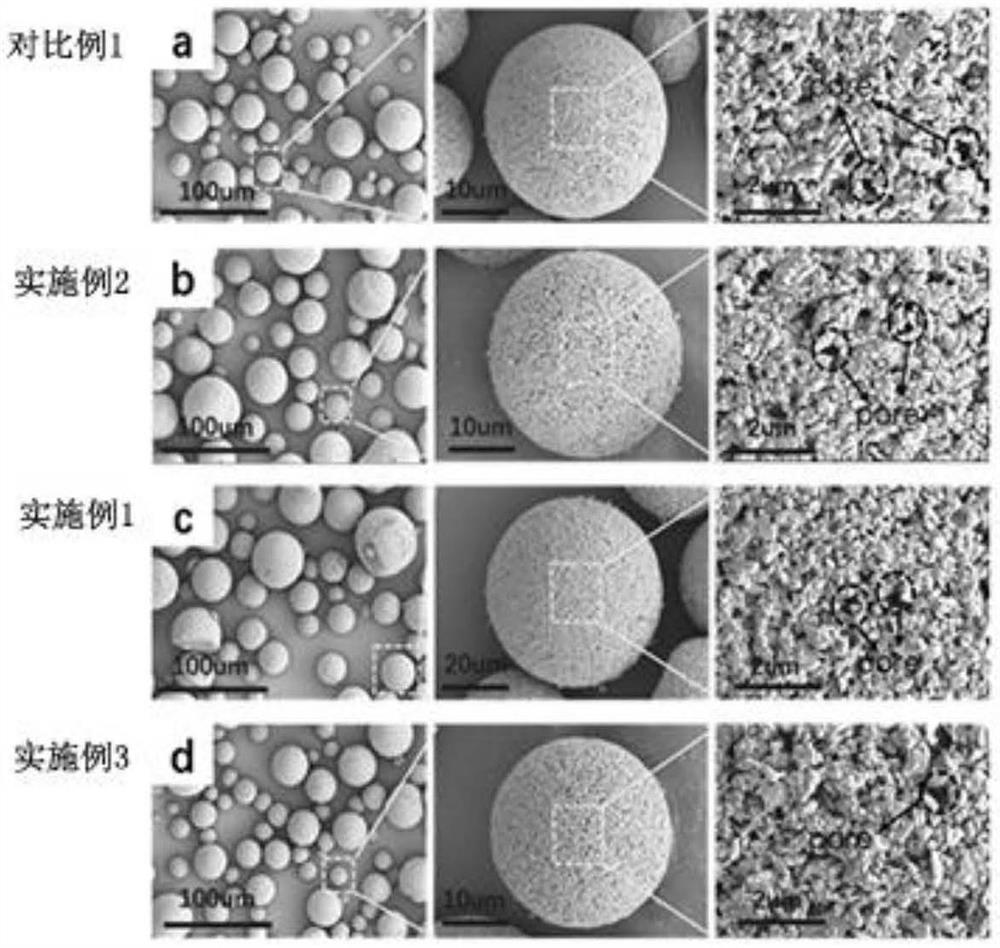

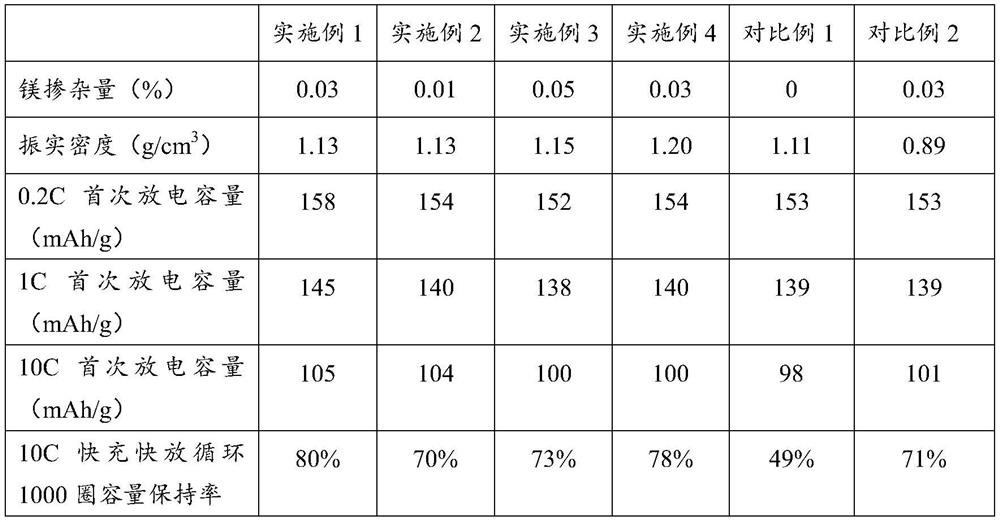

[0030] An embodiment of the present invention provides a method for preparing magnesium-doped lithium iron phosphate / carbon composite microspheres with high tap density, comprising the following steps:

[0031] (1) Weigh an appropriate amount of iron source, phosphorus source, lithium source, magnesium hydroxide, PEG-400, carbon source A and mix in solid phase to obtain a mixture, then add the mixture to deionized water containing zircon sand for ball milling, after ball milling Use a sieve to filter and separate the zircon sand to obtain a slurry; wherein, the molar ratio of iron, phosphorus, lithium and magnesium in the mixture is 1:1:1.01:0.01-0.05, and the mass of PEG-400 accounts for the mass of the mixture 2-5% of the mass of the carbon source accounts for 8-16% of the mass of the mixture.

[0032] (2) Spray drying the slurry obtained in step (1) to obtain a yellow-brown precursor powder;

[0033] (3) Place the yellow-brown precursor powder obtained in step (2) in a tub...

Embodiment 1

[0043] A magnesium-doped lithium iron phosphate / carbon composite microsphere with high tap density and a preparation method thereof, comprising the steps of:

[0044] (1) Weigh an appropriate amount of iron phosphate, lithium carbonate, magnesium hydroxide, glucose, and PEG-400 in solid phase to mix to obtain a mixture, then place the mixture in deionized water containing zircon sand for ball milling, and ball mill at a frequency of 50Hz for 30min After the ball milling, the zircon sand is filtered and separated by a sieve to obtain a slurry, wherein the molar ratio of iron, phosphorus, lithium and magnesium in the mixture is 1:1:1.01:0.03, and the mass of PEG-400 is the mixture 2% of the mass, the mass of glucose is 10% of the mass of the mixture, the mass ratio of deionized water to the mixture is 1.5:1, and the mass ratio of zircon sand to the mixture is 12:1.

[0045] (2) Spray drying the slurry obtained in step (1) at a feed rate of 30mL / min, an atomization disc frequency...

Embodiment 2

[0048] A magnesium-doped lithium iron phosphate / carbon composite microsphere with high tap density and a preparation method thereof, comprising the steps of:

[0049] (1) Weigh an appropriate amount of iron phosphate, lithium carbonate, magnesium hydroxide, glucose, and PEG-400 in solid phase to mix to obtain a mixture, then place the mixture in deionized water containing zircon sand for ball milling, and ball mill at a frequency of 50Hz for 30min After ball milling, the zircon sand is filtered and separated with a sieve to obtain a slurry, wherein the molar ratio of iron, phosphorus, lithium and magnesium in the mixture is 1:1:1.01:0.01, and the mass of PEG-400 is the mixture 2% of the mass, the mass of glucose is 10% of the mass of the mixture, the mass ratio of deionized water to the mixture is 1.5:1, and the mass ratio of zircon sand to the mixture is 12:1.

[0050] (2) Spray drying the slurry obtained in step (1) at a feed rate of 30mL / min, an atomization disc frequency o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap