Pipeline inner wall poly-p-xylylene coating equipment and coating method

A technology of parylene and coating equipment, which is used in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problem that the protection process cannot be widely used, is inconvenient for the production of coating for long pipeline products, and is unfavorable for batch production. Production costs and other issues, to achieve the effect of facilitating transfer and cooperating with the nearest engineering site application, improving the effective utilization rate, and reducing the cost of coating production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

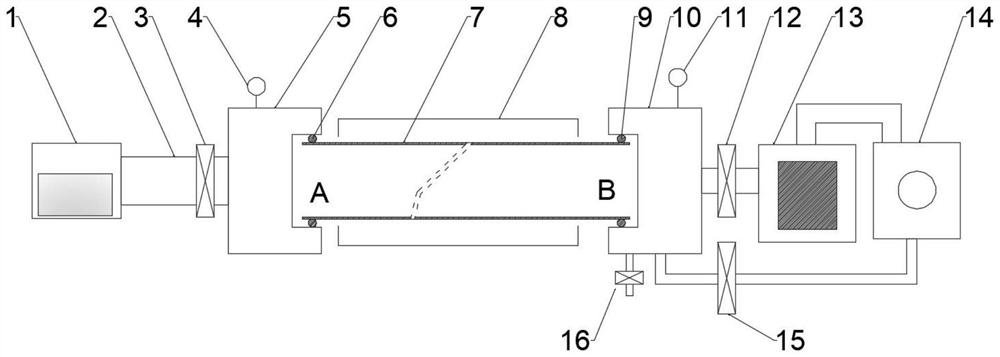

[0033] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0034] A kind of pipeline inner wall parylene coating equipment, this coating equipment is used for forming the parylene film on the inner wall of pipeline workpiece, especially long pipeline workpiece, such as figure 1 As shown, the coating equipment of the present invention comprises the pipeline workpiece 7 to be coated, and the pipeline workpiece 7 to be coated is the product to be coated, and it plays the effect of deposition chamber in the coating equipment, and forms a complete parylene together with other parts Coating equipment; the coating equipment of the present invention also includes evaporation furnace 1, cracking furnace 2, process valve 3, process vacuum gauge 4, first pipeline docking mechanism 5, first sealing rubber ring 6, pipeline cooling cover 8, second sealant Circle 9, second pipeline docki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com