High-binding-force optical thin film of diamond crystal and preparation method of high-binding-force optical thin film

An optical thin film and diamond technology, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of diamond coating technology such as difficulty, low damage resistance, film instability, etc., to improve the film system Surface binding force, improve coating effect, improve stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

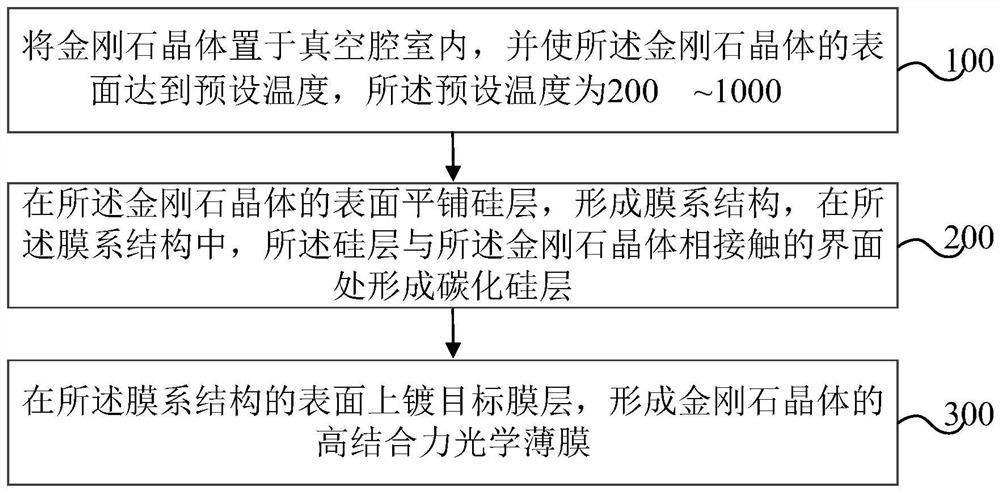

[0029] On the one hand, the present invention provides a kind of preparation method of the high cohesive force optical film of diamond crystal, please refer to figure 1 as shown, figure 1 It is a flow chart of a method for preparing a diamond crystal high-binding force optical film provided in an embodiment of the present invention. The preparation method includes the following steps:

[0030] Step 100, placing the diamond crystal in a vacuum chamber, and making the diamond surface reach a preset temperature, and the preset temperature is 200°C-1000°C.

[0031] In step 200, a silicon layer is spread on the surface of the diamond crystal to form a film structure, and in the film structure, a silicon carbide layer is formed at the interface between the silicon layer and the diamond crystal.

[0032] Step 300, coating a target film layer on the surface of the film structure to form a diamond crystal-based film structure.

[0033] In this step 300 , specifically, the step of pla...

Embodiment 1

[0046] In the present embodiment, the preparation method of the high bonding force optical film of diamond crystal comprises the following steps:

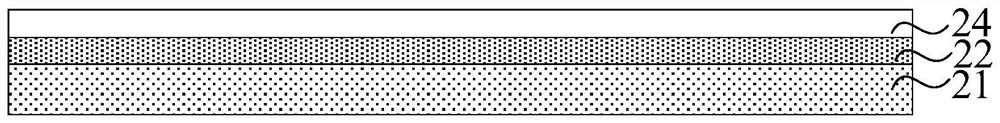

[0047] Place the diamond crystal 21 in the vacuum chamber 11 of the coating device and fix it on the stage 12. The working temperature is controlled by the pre-laying temperature controller 12 to 200°C, and the pre-laying silicon layer value of the thickness controller 15 is set. The thickness is 0.1nm, and the required silicon material is provided by the film tray 13, and a silicon layer is laid on the surface of the diamond crystal 21 by ion beam sputtering technology to form a film structure. During this process, the thickness controller 15 detects the thickness of the tiled silicon layer and feeds it back to the thickness controller 15. When the thickness of the tiled silicon layer reaches 0.1 nm, the laying of the silicon layer is stopped. During this process, the silicon carbide layer 23 is formed at the contact interface bet...

Embodiment 2

[0050] In the present embodiment, the preparation method of the high bonding force optical film of diamond crystal comprises the following steps:

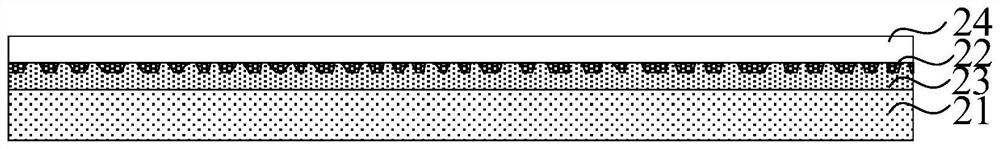

[0051] Place the diamond crystal 21 in the vacuum chamber 11 of the coating device and fix it on the stage 12. The working temperature is controlled by the pre-laying temperature controller 12 to 700°C, and the pre-laying silicon layer value of the thickness controller 15 is set. The thickness is 3nm, and the required silicon material is provided by the film tray 13, and three layers of silicon are laid on the surface of the diamond crystal 21 by electron beam evaporation technology to form a film structure. During this process, the thickness of the tiled silicon layer is detected by the thickness controller 15 and fed back to the thickness controller 15. When the thickness of the tiled silicon layer is 3 nm, the laying of the silicon layer is stopped. During this process, a silicon carbide layer 23 is formed at the interface where...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com