Gas supplementing device of tubular reactor

A tubular reactor and gas supply pipe technology, applied in electrical components, semiconductor devices, gaseous chemical plating, etc., can solve the problems of poor uniformity between sheets, unable to meet the requirements of improving the uniformity of coating thickness, etc., and achieve the optimal coating effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

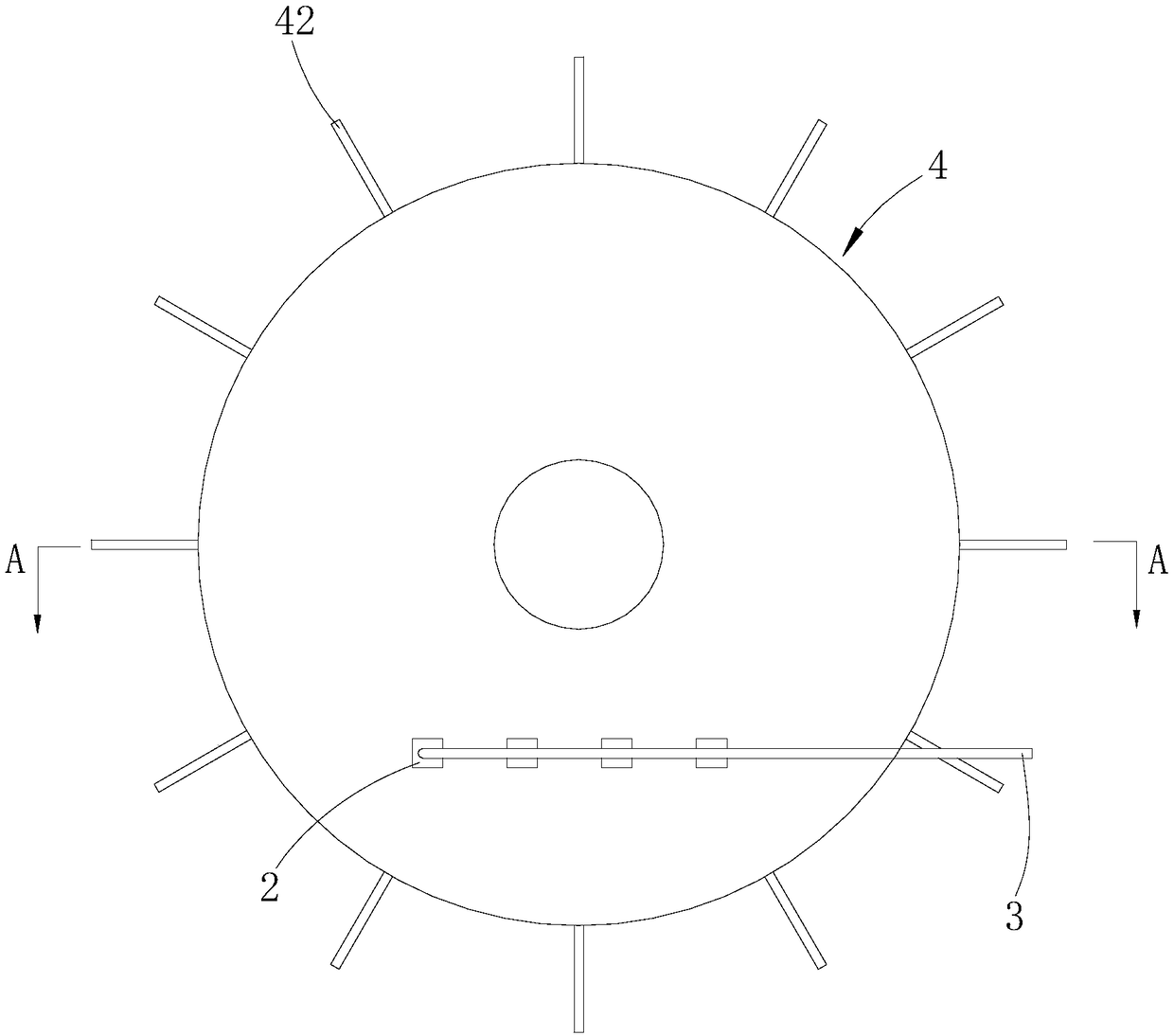

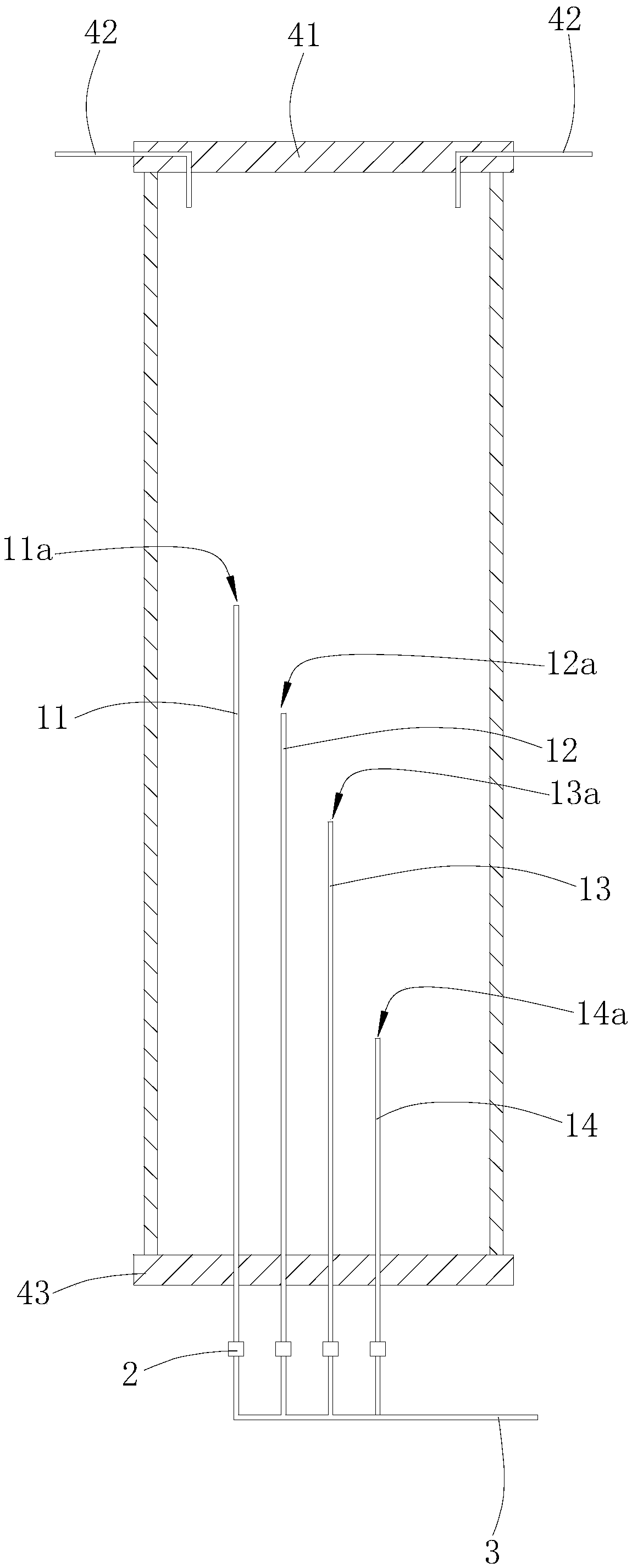

[0016] Such as figure 1 with 2 shown

[0017] The air supply device comprises four air supply pipes, a main pipe 3 and four flow control valves 2 .

[0018] The four air supply pipes are the first air supply pipe 11, the second air supply pipe 12, the third air supply pipe 13 and the fourth air supply pipe 14. The four air supply pipes have the same structure. Taking the first air supply pipe 11 as an example, the front end of the air supply pipe runs through The furnace tail cover plate 43 extends into the LPCVD tube furnace 4, and the rear end of the gas supply pipe stretches out from the rear side of the LPCVD tube furnace 4.

[0019] The distances between the four gas supply pipes extending into the LPCVD tube furnace 4 are all different. The front end of the first gas supply pipe 11 is the first air outlet hole 11a, and the length of the first air outlet hole 11a from the furnace tail cover plate 43 is equal to the axial length of the inner hole of the LPCVD tube furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com