Coating system for improving coating quality of mold core

A coating and core technology, applied in the direction of tools, manufacturing tools, casting molding equipment, etc., can solve the problems of many spray coatings, increase costs, increase labor costs, etc., achieve uniform casting surface, reduce production costs, and improve coating effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

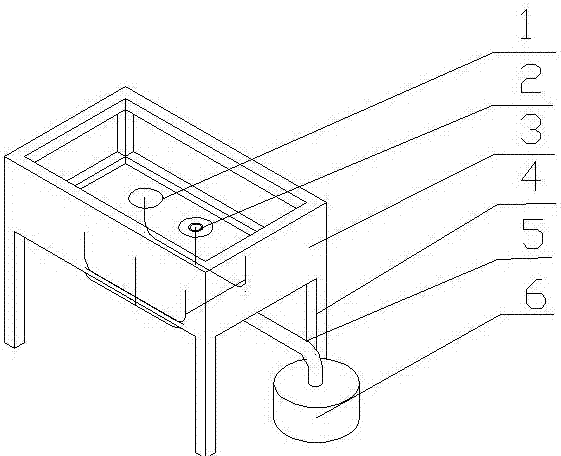

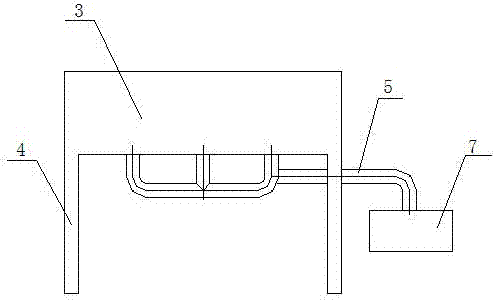

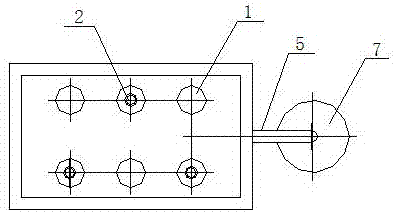

[0017] Such as Figure 1 to Figure 3 A kind of coating system that improves mold core coating quality as shown, comprises agitating fan 1, air nozzle 2, coating pool 3, frame 4, air duct 5 and air compression device 7; Described coating pool 3 bottoms are provided with There is a frame 4, and the paint pool 3 is provided with an air spray head 2 and a stirring fan 1. The air spray head 2 and the stirring fan 1 include multiple and are evenly distributed at the bottom of the paint pool 3. The air spray head 2 passes through the air duct 5 is connected with air compressor 7.

[0018] Preferably, in order to filter the paint and coat the casting more evenly, the air spray head 2 and the stirring fan 1 are arranged coaxially, and 4-8 are evenly arranged.

[0019] Such as Figure 4 Schematic diagram of the structure of the air compression ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com