Anti-corrosion coating, heat exchanger applying anti-corrosion coating and coating method

An anti-corrosion coating and heat exchanger technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of complex construction process, insufficient anti-corrosion performance, and no functionality, achieve good overall uniformity, and ensure the overall coating. The effect of uniformity and corrosion resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

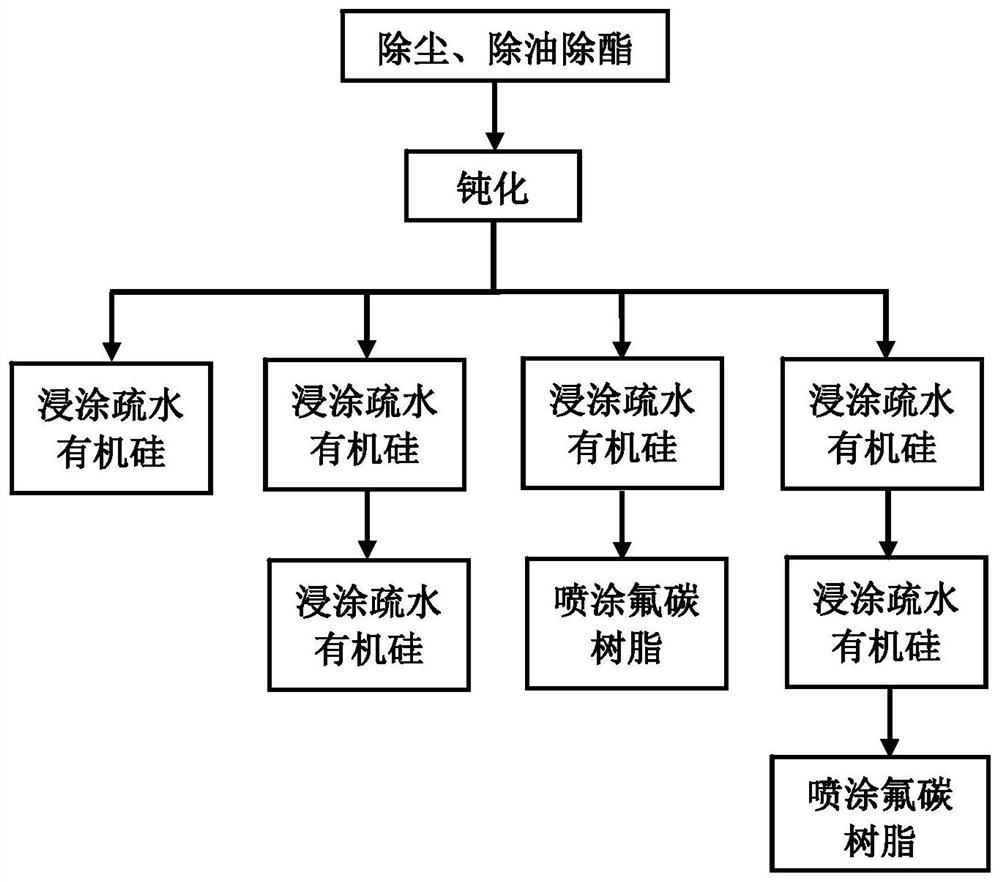

[0051] (1) Pretreatment of heat exchanger:

[0052] The heat exchanger 100 is subjected to dedusting, degreasing and degreasing and passivation treatment respectively;

[0053] (2) Coating:

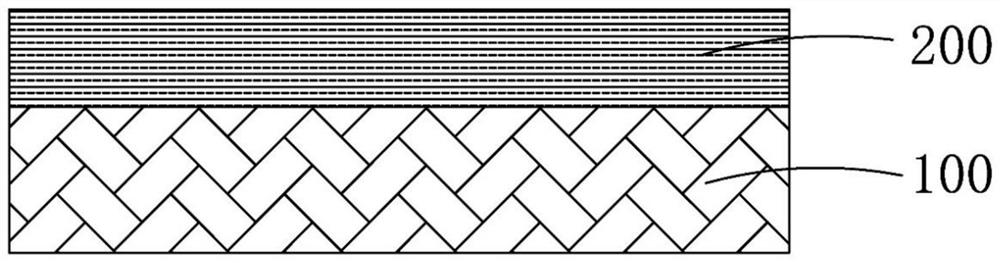

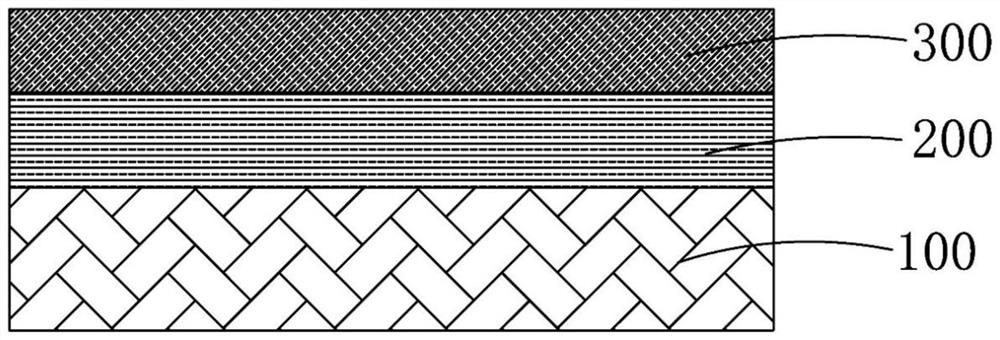

[0054] Immerse the heat exchanger 100 as a whole in the solution of the hydrophobic silicone nano-coating 200 with a concentration of 20%, let it stand for 10-30 seconds, take out the heat exchanger 100 and remove the liquid on its surface, and place the heat exchanger 100 at 100- In an oven at 150°C, let it stand still for 5-10 minutes; repeat the above actions, and then place the heat exchanger 100 in an oven at 150-200°C, and let it stand for 10-30 minutes, so that the hydrophobic silicone nano-coating 200 is cured, and then heat exchange The surface of the heat exchanger 100 is sprayed with a fluorocarbon resin coating 300, and after the fluorocarbon resin coating 300 is cured, the heat exchanger 100 is taken out and allowed to stand at room temperature.

[0055] Preferably, the fil...

Embodiment 2

[0057] (1) Pretreatment of heat exchanger:

[0058] The heat exchanger 100 is subjected to dedusting, degreasing and degreasing and passivation treatment respectively;

[0059] (2) Coating:

[0060] Immerse the heat exchanger 100 as a whole in the solution of the hydrophobic silicone nano-coating 200 with a concentration of 30%, let it stand for 10-30 seconds, then take out the heat exchanger 100 and remove the liquid on its surface, and place the heat exchanger 100 in Stand in an oven at 150-200°C for 10-30 minutes to cure the hydrophobic silicone nano-coating 200, then take out the heat exchanger 100 and let it stand at room temperature.

Embodiment 3

[0062] (1) Pretreatment of heat exchanger:

[0063] The heat exchanger 100 is subjected to dedusting, degreasing and degreasing and passivation treatment respectively;

[0064] (2) Coating:

[0065] Immerse the heat exchanger 100 as a whole in the solution of the hydrophobic silicone nano-coating 200 with a concentration of 20%, let it stand for 10-30s, then take out the heat exchanger 100 and remove the liquid on its surface, and place it at 100-150°C In the oven, let it stand for 5-10 minutes; repeat the above actions, then place the heat exchanger 100 in an oven at 150-200 ° C, and let it stand for 10-30 minutes to cure the hydrophobic silicone nano-coating 200, then take out the heat exchanger 100 Let stand to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com