Device system and process for cracking and recycling high-carbon alcohol waste liquid

A high-carbon alcohol and process technology, which is applied in the preparation of organic compounds, chemical/physical/physical chemical processes, organic chemistry, etc., can solve the problems of low utilization rate of waste liquid, increased production cost, complicated process, etc., and achieve the realization of Effects of clean conversion and efficient utilization, increased production, and improved energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

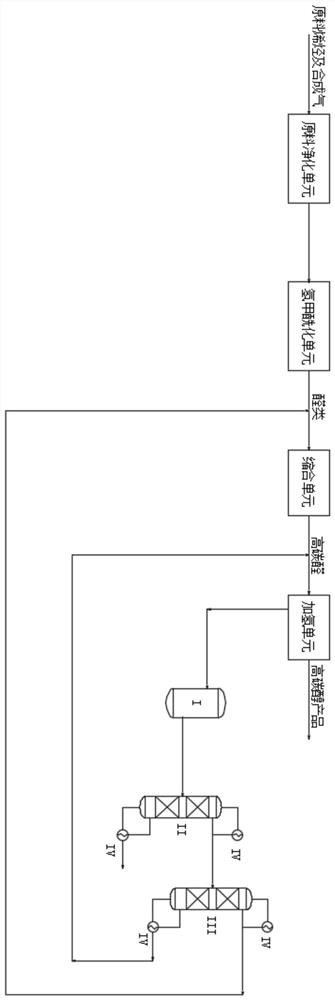

[0039] This embodiment provides a means system for a high carnol waste liquid cracking, such as figure 1 As shown, the device system includes a raw material purification unit, a hydroformation unit, a condensation unit, a hydrogenation unit, a cleavage unit I, and a rectification unit;

[0040] The rectification unit is a first distillation column and a second distillation column in series;

[0041] The waste alcohol outlet of the hydrogenation unit is connected to the inlet of the lysis unit I;

[0042] The outlet of the cleavage unit 1 is connected to the inlet of the first distillation column II;

[0043] The outlet of the top of the first distillation column II is connected to the inlet of the second distillation column III;

[0044] The second distillation column III column top of the tower is connected to the inlet connection of the condensation unit;

[0045]The restructuring of the second distillation column III tower is connected to the inlet of the hydrogenation unit;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com