Flue gas, oil gas and dust separation and recycling system of asphalt mixing station

An asphalt mixing, separation and recovery technology, applied in separation methods, solid separation, dispersed particle separation, etc., can solve problems such as environmental pollution, and achieve the effects of reducing environmental pollution, rational design, and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

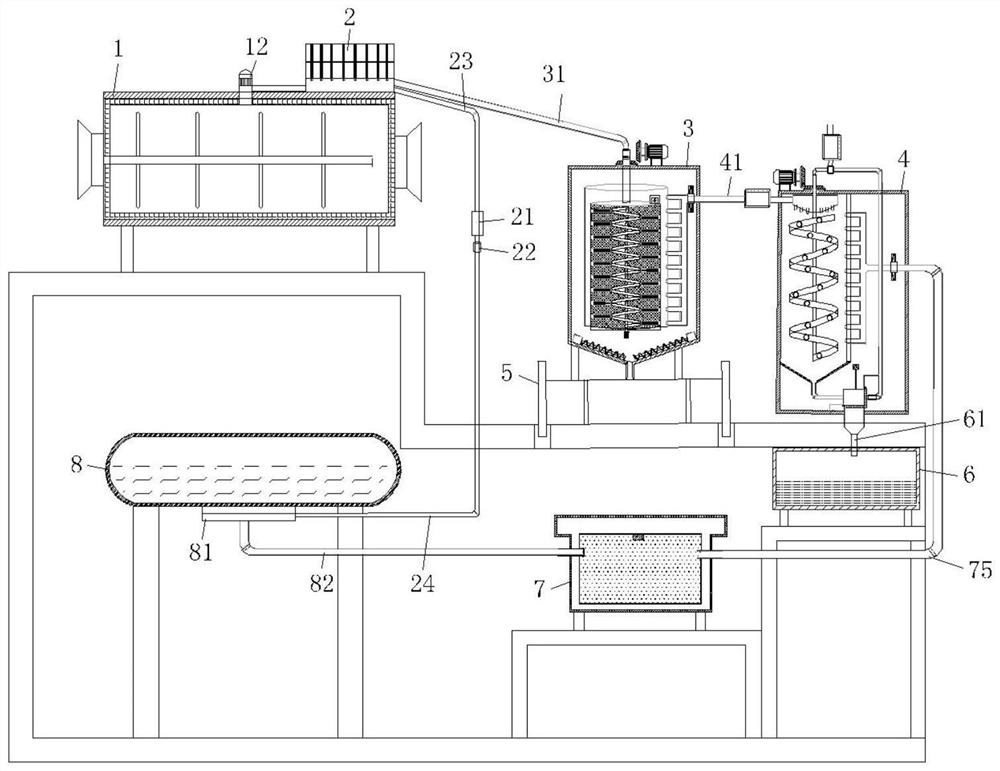

[0026] refer to figure 1 , a smoke oil gas dust separation recovery and reuse system of an asphalt mixing station, including a working box, a mixing bin 1 is installed on one side of the top surface of the working box body, and an electrical appliance is installed on the top side of the mixing bin 1 The tar catcher 2, a suction pump 12 is connected between the smoke outlet at the top of the mixing bin 1 and the input end of the electric tar catcher 2, and the oil outlet of the electric tar catcher 2 is connected to an oil collection tank 21 through a pipeline, so An oil pump 22 is installed on the lower side of the oil collecting tank 21, an asphalt tank 8 is fixed on the bottom surface of the working box close to the mixing chamber 1, and a burner 81 is installed at the bottom of the asphalt tank 8, and the output end of the oil pump 22 passes through a pipeline Connected to the oil supply end of the burner 81, the collected tar is collected in the asphalt tank burner for hea...

Embodiment 2

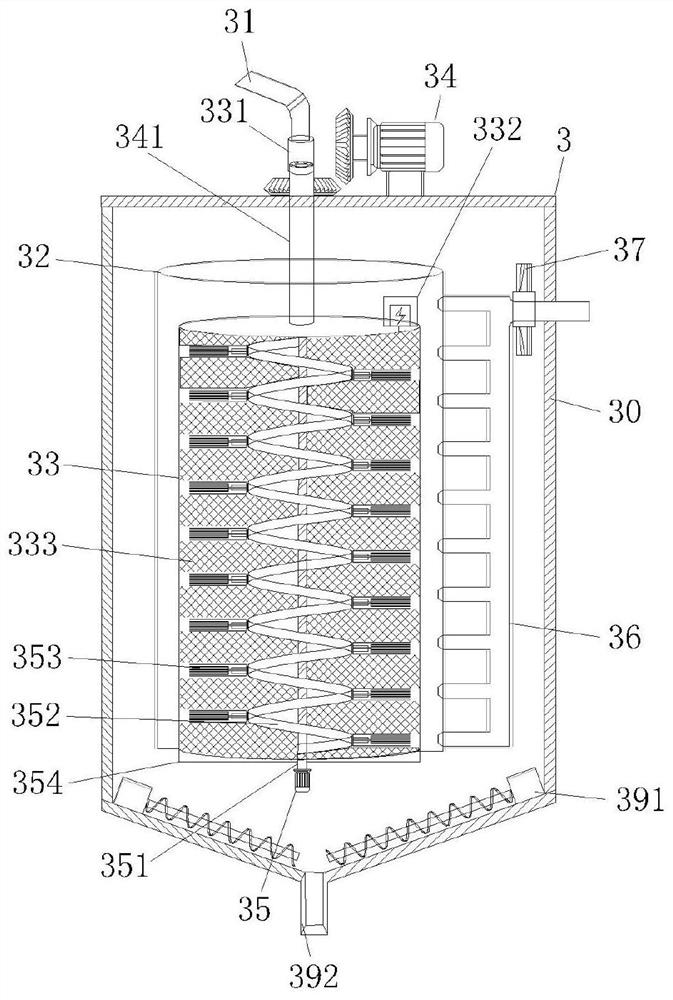

[0029] Such as figure 1 , 2 , 4 and 5, the present embodiment is basically the same as Embodiment 1. The dust screening mechanism 3 includes a screening cylinder body 30, and a large cylindrical barrel 32 and a small cylindrical barrel 32 are nested inside the screening cylinder body 30. Bucket 33, a drive motor I34 is installed in the middle of the outer top surface of the screening cylinder body 30, and a hollow rotating shaft 341 is fixed through the middle of the top of the small cylindrical barrel 33, and one end of the hollow rotating shaft 341 passes through the drive motor I34. The bevel gear set is rotationally connected, and the top end of the hollow rotating shaft 341 is connected to the dust guide pipe 31 through the rotary joint I331. A power supply assembly 332 is installed, a filter screen 333 is fixed on the side of the small cylindrical bucket 33, and a door 354 capable of opening and closing is installed at the bottom, the output end of the power supply asse...

Embodiment 3

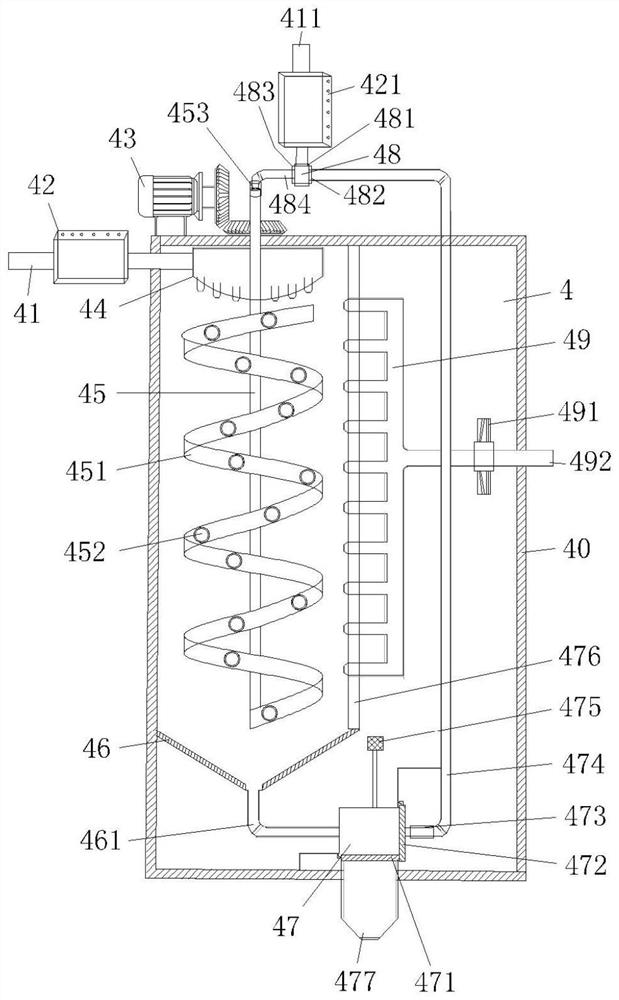

[0034] Such as figure 1 with 3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the circulating spray mechanism 4 includes a spray tank 40, a hollow shaft 45 runs through the top of the spray tank 40, and one side of the outer top surface of the spray tank 40 is fixed. There is a driving motor III 43, the output end of the driving motor III 43 is rotationally connected with the hollow shaft 45 through a bevel gear set, the hollow shaft 45 is sleeved on the outside and connected through a spiral conduit 451, and the top of the hollow shaft 45 is fixed with a rotary joint II 453, A water pipe 484 is fixed at one end of the swivel joint II 453, and a three-way valve 48 is installed on the water pipe 484. An electromagnetic flow valve I421 is connected to the upper side of the three-way valve 48, and one end of the electromagnetic flow valve I421 is connected to a water source 411. A gas flow divider 44 is provided, the inlet end of the gas flow divide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com