Preparation method of molybdenum disulfide pattern

A molybdenum disulfide and patterning technology, applied in gaseous chemical plating, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of high cost and unstable film preparation, and achieve the effect of preventing the loss of molybdenum source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

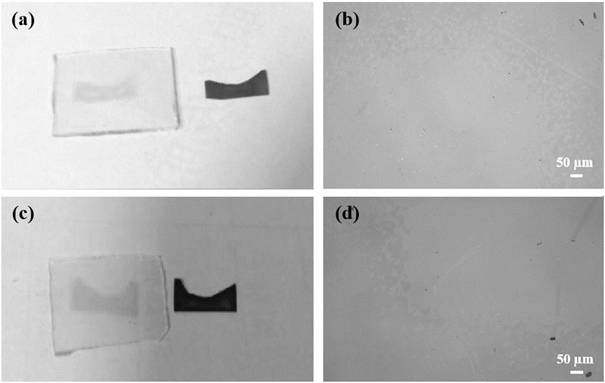

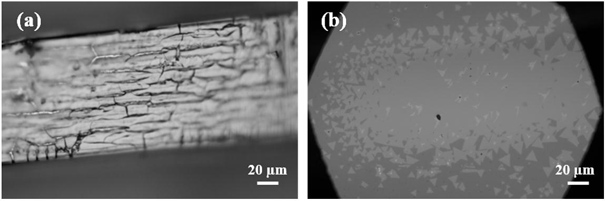

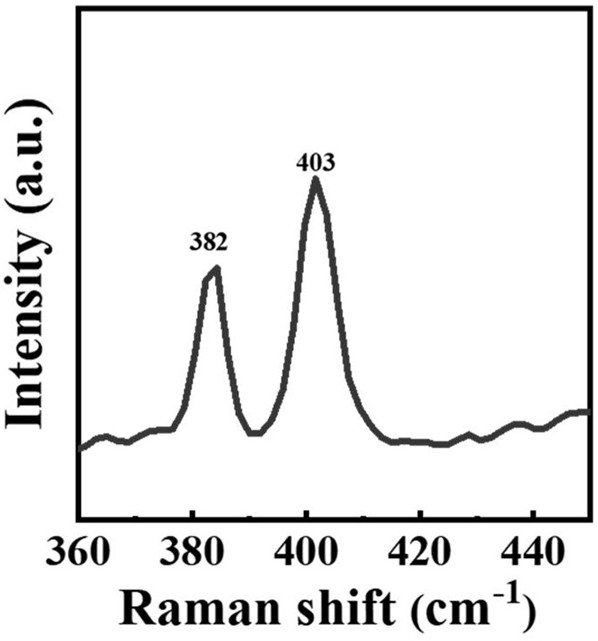

Embodiment 1

[0024] (1) Cut the custom-made Mo foil with specific graphics into a shape of suitable size, and ultrasonicate twice in absolute ethanol and water, each time for about 10 min, to remove impurities such as organic pollutants on the surface of the Mo foil;

[0025] (2) Pretreatment of Mo foil: The cleaned Mo foil was oxidized by electrochemical anodic oxidation, and the whole oxidation process was carried out in a three-electrode oxidation system, with Mo foil as the working electrode, platinum sheet as the counter electrode, and calomel electrode as the reference The specific electrode is oxidized in a special electrolyte solution, the electroplating voltage is about 0.52V, and the electroplating time is about 15 minutes. After electroplating, the oxidized Mo foil was taken out from the electrolyte, soaked in deionized water, cleaned and then dried naturally; wherein, the composition of the electrolyte was 0.15 mol / L H 2 C 2 o 4 • 2H 2 O, 0.1 mol / L Na 2 SO 4 and 0.01 mol / L...

Embodiment 2

[0029] (1) Cut the custom-made Mo foil with a specific pattern into a rectangle of 15×20 mm, and ultrasonicate it in absolute ethanol and water for about 10 min each time to remove impurities such as organic pollutants on the surface of the Mo foil;

[0030] (2) Pretreatment of Mo foil: The clean Mo foil is oxidized by electrochemical anodic oxidation method, and the whole oxidation process is carried out in a three-electrode oxidation system, Mo foil is used as the working electrode, platinum sheet is used as the counter electrode, and calomel electrode is used as the reference The electrode is oxidized in a special electrolyte solution, the electroplating voltage is about 0.58V, and the electroplating time is about 10 min. After electroplating, the oxidized Mo foil was taken out from the electrolyte, soaked in deionized water, cleaned and then dried naturally; wherein, the composition of the electrolyte was 0.15 mol / L H 2 C 2 o 4 • 2H 2 O, 0.1 mol / L Na 2 SO 4 and 0.01 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com