Cutter coating process and equipment

A tool and process technology, applied in the field of tool coating technology and equipment, can solve the problems of tool edge dulling, etc., to achieve the effect of ensuring sharpness, reducing thickness, and avoiding dullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

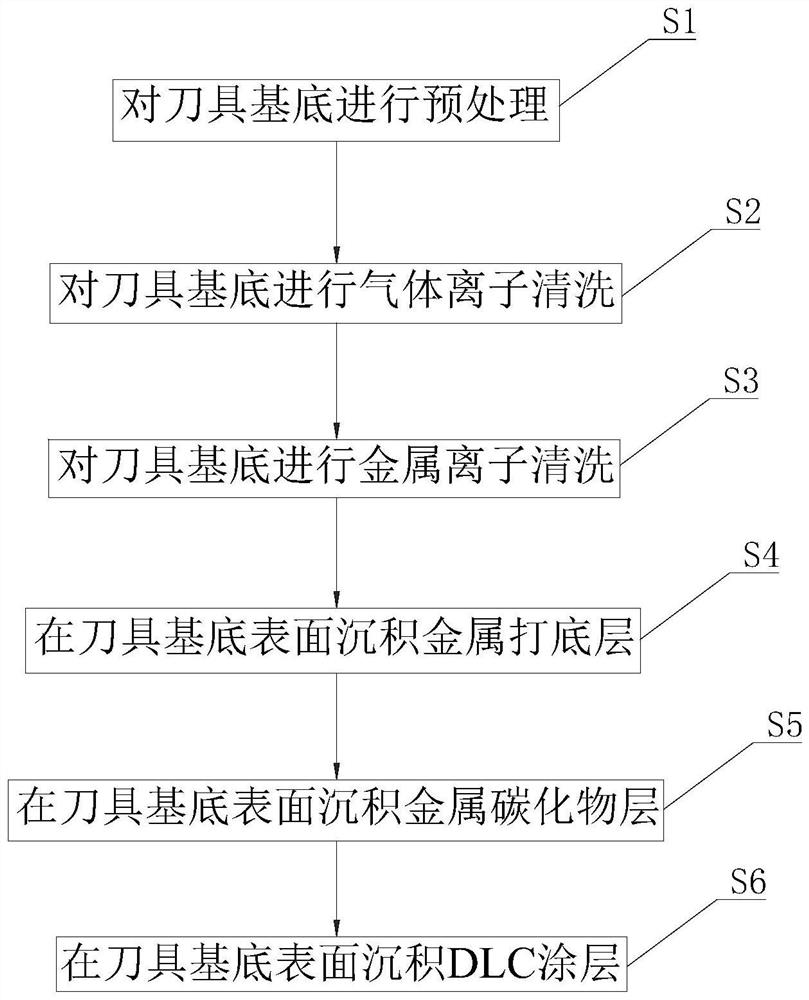

[0048] see figure 1 , the present embodiment provides a tool coating process for cutting tool base 500 (see Figure 5) to prepare a carbon film layer on the surface. In the present embodiment, the carbon film layer is a DLC (Diamond Like Carbon, diamond-like carbon) coating, and the tool coating process is a tool DLC coating coating process, comprising the following steps:

[0049] S1, perform pretreatment on the cutter base 500 .

[0050] Specifically, use the sharpened cutter as the cutter base 500, clean the cutter base 500 with alcohol and deionized water successively, then dry the cleaned cutter base 500 with a drying furnace, and place it in the drying furnace for use .

[0051] S2, cleaning the cutter base 500 with gas ions.

[0052] Specifically, the cutter base 500 is placed on the hanger in turn, and put into the turntable 100 in the DLC coating equipment with the hanger (see Figure 4 )superior. Evacuation of the DLC coating equipment and accompanying heating ...

Embodiment example

[0085] The specific implementation cases are compared as follows:

Embodiment

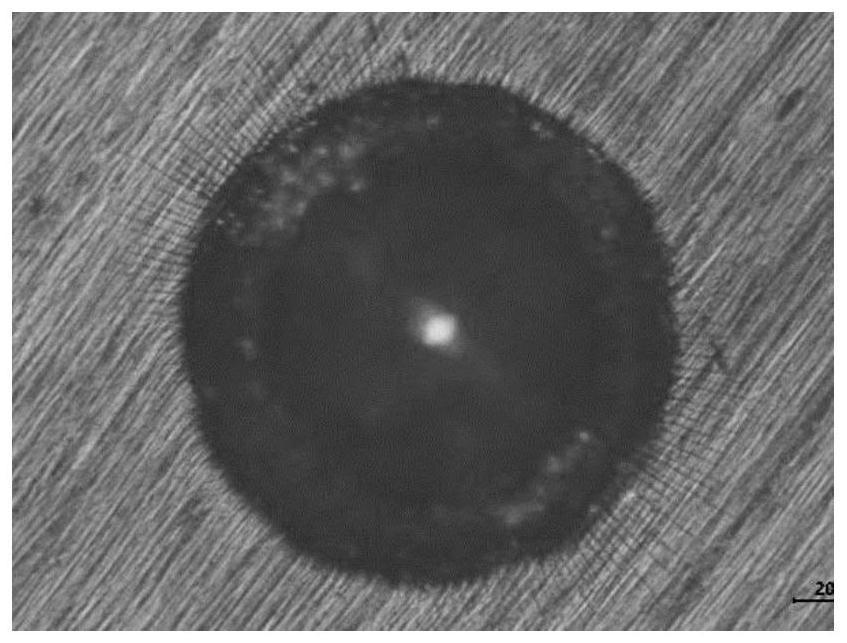

[0087] see figure 2, using the above tool DLC coating process to coat the DLC coating on the surface of the tool base 500, the hardness of the DLC coating was measured by a nanohardness tester to be 15Gpa, and the thickness of the DLC coating was measured by the ball pit method to be 0.6 μm. The adhesion of the DLC coating was measured by the indentation method. There were fine radial cracks around the indentation, but no coating peeling off, indicating that the DLC coating was well combined with the tool substrate 500, and the adhesion was H1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com