Method and system for enhancing sludge air flotation concentration reduction and harmlessness by utilizing ozone

An air flotation and sludge technology, which is applied in the direction of oxidation treatment of sludge, chemical instruments and methods, sludge treatment, etc., can solve the problems of low sludge concentration efficiency, high moisture content of concentrated sludge, and a large number of metal catalysts. Achieve the effects of reducing the risk of secondary pollution, reducing material consumption costs, and improving energy consumption and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

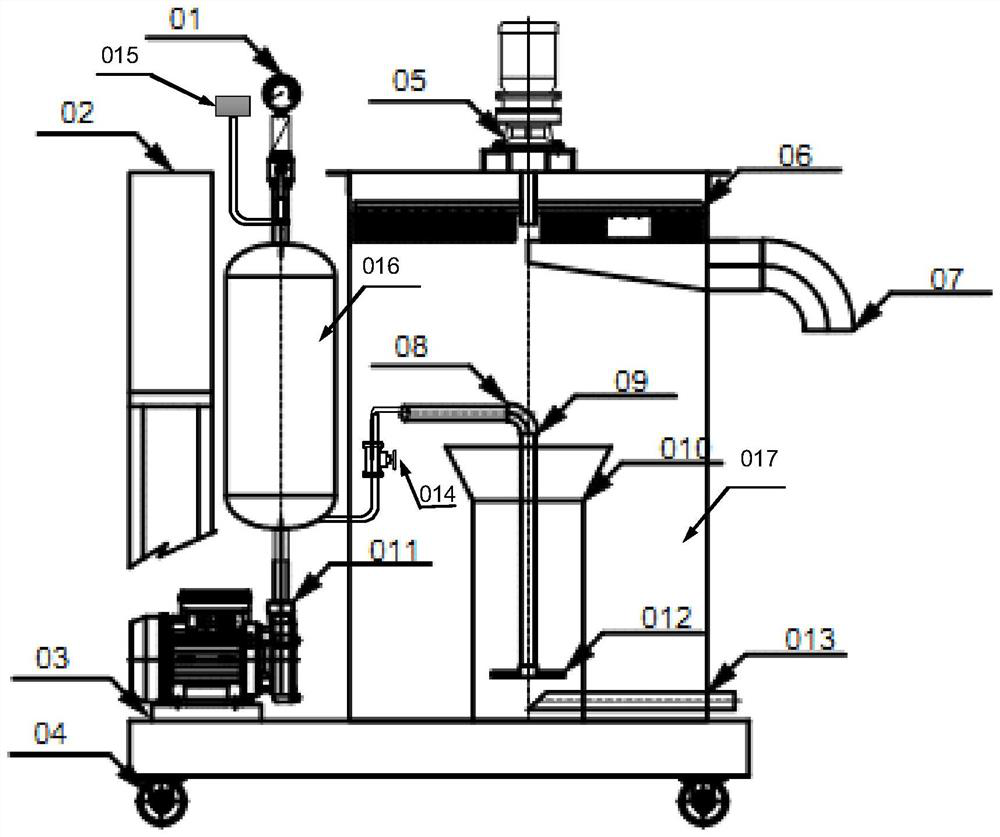

[0044] like figure 1 , a system that uses high-concentration ozone to strengthen sludge air flotation concentration reduction and harmlessness, the system includes a gas-liquid mixing pump installed on a flat base with wheels, a pressure dissolved air tank, an air flotation concentration tank, and a slag scraper , Circuit control panel 02, the whole set of equipment can move smoothly;

[0045] The gas-liquid mixing pump and its base 03 are set on the movable flatbed 04, the outlet is connected to a piston, and then vertically connected to the bottom inlet 011 of the pressure dissolved gas tank;

[0046] The pressure dissolving gas tank is oval, with an outlet at the bottom and an upper part, the upper and lower ends of the bottom are hollow hemispheres, the middle part is a hollow cylinder, and the upper part is connected with a pressure gauge, an air release valve integrated device 01 and a gas collection device 015 ;

[0047] The air flotation concentration pool 017 is a c...

Embodiment 2

[0058] A method of utilizing high-concentration ozone to strengthen sludge air flotation concentration reduction and harmlessness, the steps are as follows:

[0059] (1) Mix the mixed powder of polyacrylamide powder and polyaluminum chloride with birnessite (MnO 2 ) powder is mixed at a mass ratio of 10:1 to become an air-flotation concentrated medicament;

[0060] (2) Add 0.5‰ of air flotation concentration agent in sludge dry weight to the sludge with 98% water content and 30% mass ratio of volatile solids to total solids, mix in the air flotation concentration tank and pass through the gas-liquid The mixing pump enters the pressure container tank, and the high-concentration ozone (300mg / L) with a total dose of 1mg / g sludge dry weight passes through the micro-nano bubble generation unit to generate micro-nano bubbles with a diameter of 1um, and then enters the pressure container tank through the gas-liquid mixing pump , so that the sludge, air flotation concentration agent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com