Integral spiral non-magnetic drill rod and preparation method thereof

A non-magnetic drill pipe, spiral technology, applied in drill pipe, drilling equipment, drill pipe and other directions, can solve the problems of narrow surface adapting to stratum conditions, weak powder discharge ability, etc., to improve drilling efficiency, low construction noise, The effect of pore wall stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

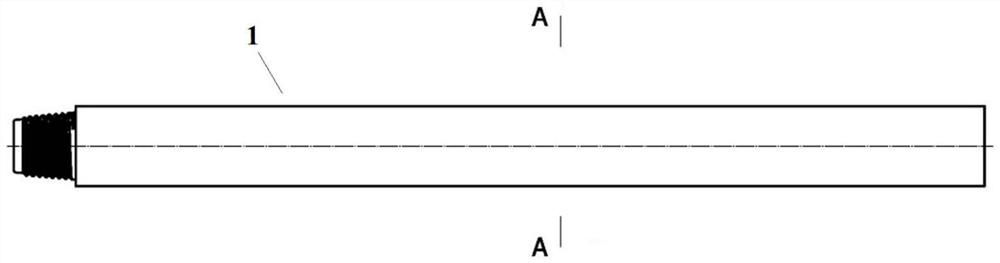

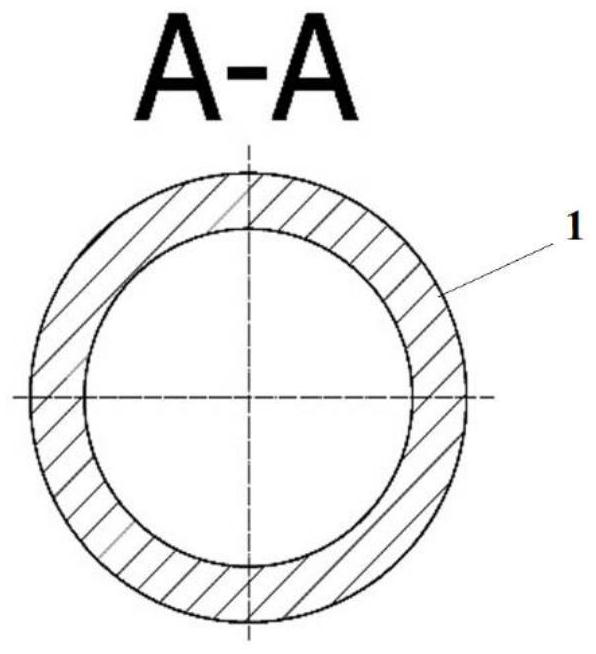

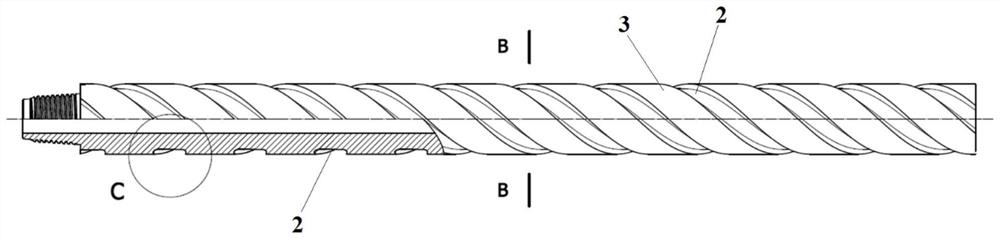

[0050] This embodiment provides a kind of integral helical non-magnetic drill rod, such as Figure 3 to Figure 5 As shown, it includes an outer flat non-magnetic drill rod 1, the outer surface of the outer flat non-magnetic drill rod 1 has a plurality of spiral grooves 2, and spiral fins 3 are formed between the spiral grooves 2;

[0051] The depth H1 of the spiral groove 2 is 5-10mm;

[0052] The width W of the spiral groove 2 is 15-25mm.

[0053] As a preferred solution of this embodiment, there are 1 to 3 spiral grooves 2 .

[0054] As a preferred solution of this embodiment, the flattened non-magnetic drill pipe 1 includes a non-magnetic male joint 101 , a non-magnetic drill pipe body 102 and a non-magnetic female joint 103 arranged coaxially in sequence.

[0055] As a preferred solution of this embodiment, the flat outer non-magnetic drill rod 1 is a hollow structure.

[0056] In this example, if figure 1and figure 2 It can be seen that the surface of the flat non-m...

Embodiment 2

[0060] This embodiment provides a kind of preparation method of integral helical non-magnetic drill rod, and this method comprises the following process:

[0061] Step one, such as Figure 6 As shown, the non-magnetic male joint 101, the non-magnetic drill pipe body 102 and the non-magnetic female joint 103 are welded together by friction welding to form an outer flat non-magnetic drill pipe 1;

[0062] Step two, such as Figure 7 As shown, the spiral groove 2 is milled on the basis of the outer flat non-magnetic drill rod 1, and the milling of the spiral groove 2 is carried out on a CNC milling machine, and the outer flat non-magnetic drill rod 1 is fixed in the Z-axis direction of the milling machine;

[0063] Step three, such as Figure 8 As shown, each helical groove 2 is correspondingly arranged with a milling cutter 4, and the pitch P corresponding to each helical groove 2 is set, and then processed to form, as follows: image 3 The integral helical non-magnetic drill...

Embodiment 3

[0065] This embodiment provides a method for preparing an integral helical non-magnetic drill pipe, which is basically the same as that of Embodiment 2, the only difference being that in step 1, the friction welding in this embodiment adopts the combination of continuous drive friction welding and electric field welding method, such as Figure 11 method shown. And friction welding adopts independent continuous drive friction welding method among the embodiment 2, promptly as Figure 9 method shown.

[0066] Specifically, such as Figure 11 and Figure 12 As shown, the specific process of friction welding using the combined welding method of continuous drive friction welding and electric field is: in this method, the non-magnetic male joint 101, the non-magnetic female joint 103 and the non-magnetic drill pipe body 102 are respectively connected by a friction welding machine tool. 5 Friction welding is completed;

[0067] An annular electrode 6 is set on the nonmagnetic dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com